Tuesday July-08 2025 17:46:07

Soil sieve analysis is a soil particle size determination method based on the principle of mechanical separation. It is mainly used to analyze the content and distribution of coarse particles (usually larger than 0.075 mm or 0.063 mm) in the soil. By classifying soil samples through sieves with different apertures, the proportion of sand (0.05–2 mm), silt (0.002–0.05 mm) and clay (<0.002 mm) is determined to reveal the soil texture and structural characteristics.

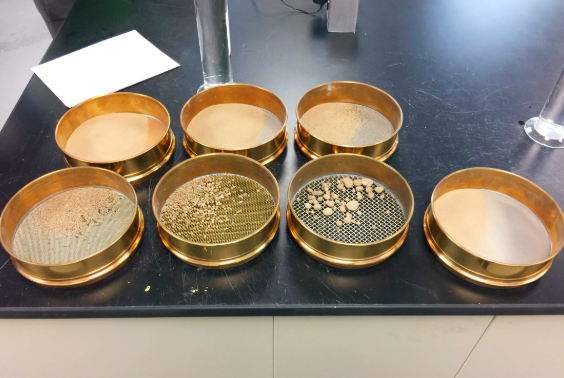

Its core feature is to use a series of standard sieves with gradually decreasing apertures to separate and retain soil particles of different sizes on the sieve surface through vibration, thereby achieving classification according to particle size.

Soil sieving analysis is a simple and effective method for determining the particle size distribution of soil particles. Its working principle is mainly to use sieve holes of different sizes to separate soil samples into different particle size components. When a dry soil sample passes through a series of sieves with apertures arranged from large to small, soil particles of different sizes will pass through or stay on a specific sieve due to gravity and vibration.

Soil sieving analysis is a commonly used soil particle size analysis method, which is mainly used to determine the content of particles larger than a certain particle size (usually 0.063 mm or 0.075 mm) in the soil. Based on the principle of mechanical separation of particle size. The particles in the soil sample are classified according to their size through a series of standard sieves with gradually decreasing apertures. When the particle size is smaller than the sieve hole, they will pass through the sieve hole; when the particle size is larger than the sieve hole, they will be retained on the sieve surface.

|

Texture category |

sand (1~0.05mm) |

silt (0.05~0.002mm) |

clay (<0.002mm) |

|

Sand |

>80% |

<10% |

<10% |

|

Loam |

40%~80% |

30%~45% |

10%~30% |

|

Clay |

<40% |

<40% |

>30% |

Understand the composition of soil particles: Soil is composed of particles of different sizes, such as sand, silt, clay, etc. Sieving analysis can determine the relative content of these different particle size components.

Determine the soil particle size distribution: Understand the content of sand (0.05–2 mm), silt (0.002–0.05 mm) and clay (<0.002 mm) in the soil.

Evaluate soil properties: Particle composition directly affects the physical properties of the soil, such as water permeability, water retention, aeration, fertility, etc., which in turn affects the engineering properties and agricultural production performance of the soil.

Soil sieve mesh sizes range from a few millimeters to tens of microns to meet different analytical and experimental needs. The following are some common soil sieve mesh sizes and their typical uses:

Coarse sieve (large aperture): 10mm, 20mm, 40mm, 60mm, etc.

Purpose: Mainly used to remove larger impurities in the soil, such as stones, plant residues, debris, etc., to prepare for subsequent fine screening.

Medium sieve (medium aperture): 1mm, 2mm, 2.5mm, 3mm, 4.75mm (No.4 sieve)

Purpose: Used to distinguish between coarse sand, fine sand and other particle sizes. In soil physical property analysis, 4.75mm (No.4 sieve) is usually used as the boundary to distinguish between coarse aggregate and fine aggregate.

Fine sieve (small aperture, high mesh): 0.075mm (No.200 sieve), 0.15mm (100 mesh), 0.25mm (60 mesh), 0.5mm (35 mesh)

Purpose: This is the most commonly used sieve size in soil particle size analysis.

|

Model number |

screen frame diameter |

screen frame height |

screen mesh number (Mesh) |

screen hole size (mm) |

screen frame material |

screen material |

|

TS200-4.75 |

200 mm |

50 mm |

4 mesh |

4.75 mm |

stainless steel |

stainless steel |

|

TS200-2.00 |

200 mm |

50 mm |

10 mesh |

2.00 mm |

stainless steel |

stainless steel |

|

TS200-0.85 |

200 mm |

50 mm |

20 mesh |

0.85 mm |

stainless steel |

stainless steel |

|

TS200-0.425 |

200 mm |

50 mm |

40 mesh |

0.425 mm |

stainless steel |

stainless steel |

|

TS200-0.25 |

200 mm |

50 mm |

60 mesh |

0.25 mm |

stainless steel |

stainless steel |

|

TS200-0.15 |

200 mm |

50 mm |

100 mesh |

0.15 mm |

stainless steel |

stainless steel |

|

TS200-0.075 |

200 mm |

50 mm |

200 mesh |

0.075 mm |

stainless steel |

stainless steel |

|

TS200-Blank |

200 mm |

50 mm |

no hole (bottom plate) |

/ |

stainless steel |

/ |

Soil sieving analysis is divided into dry sieving method and wet sieving method. Choose the appropriate method according to the soil type and analysis requirements.

① Dry sieving method: suitable for soils with low water content and weak viscosity (such as sandy soil).

Collect soil samples, air dry or oven dry (usually at 105℃), and remove organic matter, roots and impurities. Weigh a certain mass of dry soil sample (usually 100-500g). Place the soil sample on a standard sieve group (arranged in order from large to small apertures, such as 2mm, 1mm, 0.5mm, 0.25mm, 0.1mm, etc.). Sieve by manual or mechanical vibration, usually for 5-10 minutes. Weigh the mass of soil remaining on each sieve separately and calculate the percentage of each particle size range. According to the sieving results, draw a particle size distribution curve or calculate the proportion of each particle size.

② Wet sieving method: suitable for soils with more clay or silt, because dry sieving may cause particle agglomeration.

Soak the soil sample in water and add a dispersant (such as sodium hexametaphosphate) to disperse the clay particles. Rinse the soil sample through the sieve with water flow to separate larger particles (such as sand particles). For fine particles (silt and clay) that pass through the smallest sieve holes, they are usually further analyzed in combination with sedimentation methods (such as hydrometer method or pipette method). The particles on each sieve are dried and weighed to calculate the ratio of each particle size.

Soil sieves are widely used in various fields, and their core use is to separate and classify soil according to particle size. In agricultural production, soil sieves are used to analyze soil texture, which directly affects the permeability, aeration and fertilizer retention capacity of crops, and helps farmers choose appropriate planting methods and fertilization strategies. For example, by screening to understand the ratio of sand, silt and clay in the soil, it can be determined whether the soil is sandy, loam or clay, and thus determine whether the soil needs to be improved.

In addition, in the field of civil engineering, soil sieves can be used to analyze the particle size of roadbeds, foundations and fillers, evaluate their bearing capacity, permeability and compaction, and ensure the stability and safety of engineering structures such as roads, buildings and dams. For example, when building a highway, the roadbed materials will be strictly screened to meet the grading requirements of the design and avoid later settlement or deformation.

Sample preparation: Spread the air-dried soil sample flat on a clean wooden board and crush it with a pestle with a rubber head (to avoid damaging the soil particles). Pass the 2mm sieve, grind the soil sample on the sieve and pour it back into the 2mm sieve, and use the soil sample under the sieve as the sample to be tested. Weigh the mass of the soil sample on the sieve (m₁), calculate its percentage of the total soil sample, and use it as the coarse particle content.

Sieving analysis

① Coarse sieving analysis (>0.075mm particles): Weigh the soil sample that passes the 2mm sieve (m₂), pour it into the top sieve (2mm sieve) of the sieve group stacked from top to bottom according to the aperture size (such as 2mm, 1mm, 0.5mm, 0.25mm, 0.10mm, 0.05mm sieve), place it on a vibrating sieve machine for 10 minutes, and then sieve it one by one on a clean shallow plate according to the sieve sequence, starting from the sieve with the largest aperture, until the sieve out per minute does not exceed 1% of the total sample. The particles that pass through are added to the next sieve and sieved together with the sample in the next sieve, in order, until all the sieves are sieved. Weigh the mass of the sample on each sieve to an accuracy of 0.1g. The sum of the sieve residue of each sieve and the remaining amount in the bottom plate and the total amount of the sample before sieving shall not differ by more than 1%.

② Fine sieve analysis (<0.075mm particles): If it is necessary to determine the composition of particles smaller than 0.075mm, the sieve residue of each sieve after sieving and the remaining soil sample in the bottom plate can be combined, further ground with a mortar, and then the fine particle content can be determined by sedimentation method (such as hydrometer method) or laser particle size analyzer.

Result calculation: With the cumulative content of soil particles smaller than a certain particle size as the ordinate and the particle size as the abscissa, draw a particle size distribution curve on semi-logarithmic coordinate paper, and find out the percentage of soil particles smaller than a certain particle size in the total mass according to the curve to determine the soil particle composition.

Soil sieving analysis is used to show the mass distribution and cumulative passing rate of soil on each sieve aperture, which is commonly seen in laboratory soil particle grading tests.

|

Serial number |

sieve hole size (mm) |

sieve number (ASTM) |

mass per sieve (g) |

cumulative mass on sieve (g) |

cumulative mass under sieve (g) |

cumulative percentage under sieve (%) |

|

1 |

4.75 |

No. 4 |

15.0 |

15.0 |

985.0 |

98.5% |

|

2 |

2.00 |

No. 10 |

60.0 |

75.0 |

925.0 |

92.5% |

|

3 |

0.85 |

No. 20 |

120.0 |

195.0 |

805.0 |

80.5% |

|

4 |

0.425 |

No. 40 |

250.0 |

445.0 |

555.0 |

55.5% |

|

5 |

0.25 |

No. 60 |

180.0 |

625.0 |

375.0 |

37.5% |

|

6 |

0.15 |

No. 100 |

140.0 |

765.0 |

235.0 |

23.5% |

|

7 |

0.075 |

No. 200 |

80.0 |

845.0 |

155.0 |

15.5% |

|

8 |

Chassis |

- |

155.0 |

1000.0 |

0.0 |

0.0% |

The soil sample must be fully air-dried, and the wet soil sample must be dried before being crushed to avoid particle adhesion affecting the screening results. Avoid excessive force to damage the soil particles during the screening process, especially for soils with strong structure.

The screening time of the vibrating screen can be adjusted according to the properties of the soil sample, and the screening time of clay soil needs to be appropriately extended. When analyzing fine particles, if the soil sample contains organic matter or calcium carbonate, it must be pretreated first (such as removing organic matter with hydrogen peroxide and removing calcium carbonate with hydrochloric acid).

In short, soil sieving analysis is an indispensable first step in understanding the physical properties of soil and conducting engineering classification. It is a classic and important method for determining the physical properties of soil. Through standardized operation and accurate data processing, it can provide reliable particle size information for soil science, engineering practice and environmental management.

What is the wet sieving process?

Wet sieving process is a sieving process assisted by a liquid (usually water or a solution containing a dispersant) to more effectively...

Fines content tester can be defined as an instrument used to quantitatively determine the content of fines powder components of a specific fineness...

Micro silica powder particle size analysis test sieve

Micro silica powder, also known as silica fume, is an ultrafine active silica material with a very small particle size, usually between 0.1-0.3 microns, which...

Agricultural gruesos Test sieves

Agricultural gruesos test sieves are experimental equipment used for particle size analysis, grading and testing of agricultural soil, gruesos...

Stainless steel frame and woven cloth

The test sieve is a laboratory equipment used for particle size analysis. Its core components usually include a stainless steel frame and woven cloth (also called a sieve)...

ASTM standard soil analysis sieves with pan and cover

ASTM standard soil analysis sieve is a special test sieve manufactured according to the American Society for Testing and Materials (ASTM) E11 standard, mainly used to...

Jul 08, 2025

Soil sieving analysis uses dry or wet sieving to separate soil particles by size. Dry sieving is suit...

Jul 08, 2025

Powder test sieve is a device used to analyze the particle size distribution of powdered materials. I...

Jul 07, 2025

Top impact sieve for particle size inspection

Top impact sieve for particle size inspection is set with 2-5 layers of screens. Mesh size of each la...

Jul 07, 2025

Standard Test Method for Particle-Size Analysis of Soils

Soil particle size analysis mainly uses sieving method (applicable to coarse-grained soil, such as gr...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap