Wednesday May-07 2025 16:51:19

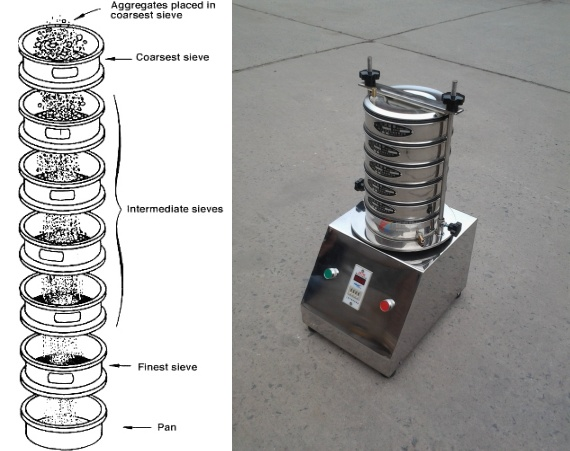

Stainless steel grain granule test sieve for lab is an important tool for analyzing the size distribution of grains, seeds, and granular materials, screening impurities or performing quality control. The sieve is made of 304 stainless steel, which is corrosion-resistant and easy to clean. The commonly used diameter is Φ200mm. The mesh size range is wide, and different specifications such as 4 mesh (4.75mm), 10 mesh (2.00mm), 20 mesh (0.85mm), and 40 mesh (0.425mm) can be selected. Users can use 5 to 8 layers of sieves according to the particle size of the material, and cooperate with the electric vibrating screen to achieve efficient and accurate particle classification. It is an indispensable tool for laboratory particle size testing.

Using a vibration motor as a vibration source, the vibration motor drives the sieve base to vibrate, and then transmits the vibration to the standard test sieve installed on the base. The grain particles are placed on the sieve. Under the action of vibration, particles smaller than the sieve holes pass through the sieve holes and fall to the lower sieve or the bottom of the sieve, while particles larger than the sieve holes remain on the sieve, thereby achieving the separation and screening of grain particles of different particle sizes, and achieving the purpose of particle size analysis and classification of grain particles.

Sieve frame: Common sieve frame diameters are 75mm, 100mm, 200mm, 300mm and 400mm. Smaller sieve frames are suitable for screening tests of small quantities of samples, while larger sieve frames can be used to process larger batches of grain particles.

Screen: Stainless steel wire mesh with apertures ranging from 0.045mm (325 mesh) to 25mm (0.98 inches).

Screen cover and chassis: Sealed design prevents material leakage, and the chassis can collect the finest particles.

Number of screen layers: Usually 6-12 layers, stacked from large to small according to aperture.

|

Mesh number (Mesh) |

Aperture (mm) |

Example of applicable grains |

|

4 mesh |

4.75 |

Separation of large grain corn and beans |

|

8 mesh |

2.36 |

Preliminary screening of wheat and brown rice |

|

12 mesh |

1.70 |

Grading of wheat impurities |

|

20 mesh |

0.85 |

Detection of broken rice grains |

|

40 mesh |

0.425 |

Flour particle size analysis (such as distinguishing whole wheat flour from refined flour) |

|

60 mesh |

0.25 |

Fine grain powder (such as rice flour, corn starch) |

|

100 mesh |

0.15 |

Ultrafine particles or impurity retention (need to be matched with a vibrating screen) |

Avoid the problem of grain particle adhesion: Grain particles are prone to adhesion due to surface humidity, static electricity, etc., which affects the screening effect. Stainless steel grain granule test sieve for lab is usually equipped with a vibration device, which separates the particles from each other through vibration of appropriate frequency and amplitude, prevents adhesion, and allows the particles to pass through the sieve smoothly.

Prevent grain particles from clogging the sieve holes: Grain particles are uneven in size and irregular in shape, which are easy to clog the sieve holes. The test sieve uses a special mesh weaving technology to make the mesh holes regular in shape and smooth in edges, reducing the chance of particles getting stuck in the mesh holes. Some sieves are designed as conical mesh holes with large inlets and small outlets, which help particles pass quickly and are not easy to get stuck.

Solve the problem of grain particle breakage: During the screening process, in order to avoid grain particles being broken due to excessive collision or extrusion, the stainless steel grain granule test sieve for lab adopts a relatively gentle screening method. The vibration intensity and frequency can be adjusted according to the characteristics of the grain particles to reduce the impact force between particles and between particles and the sieve, and reduce the particle breakage rate.

Dealing with the difficulty of irregular particle screening: Long strips (such as oats) or flat particles (such as buckwheat) are easy to get stuck or stay horizontally. Change the trajectory of particle movement through horizontal and vertical composite vibration. Special-shaped mesh holes can be customized, and rectangular holes (such as 2mm×5mm) are suitable for long particle directional screening. The screening time of irregular particles is extended to 15-20 minutes to ensure full classification.

The mesh size selection of stainless steel grain granule test sieve for lab use should be determined based on the particle size range of the grains or particles being tested. The following are the recommended mesh combinations for common types of grains, which are used for reference in particle size classification analysis:

|

Grain type |

Recommended mesh combination (mesh) |

Corresponding aperture (mm) |

Application description |

|

Corn kernels |

4 mesh, 6 mesh, 8 mesh, 10 mesh |

4.75 ~ 2.00 mm |

Preliminary classification of coarse grains, medium grains, and fine grains |

|

Wheat |

8 mesh, 10 mesh, 14 mesh, 20 mesh |

2.36 ~ 0.85 mm |

Analysis of whole grains, broken grains, and broken powder, etc. |

|

Paddy/rice |

6 mesh, 10 mesh, 14 mesh, 20 mesh, 30 mesh |

3.35 ~ 0.60 mm |

Judge the broken rice rate and whole rice rate |

|

Sorghum |

10 mesh, 16 mesh, 20 mesh, 30 mesh |

2.00 ~ 0.60 mm |

Conventional particle size distribution test |

|

Beans |

4 mesh, 6 mesh, 8 mesh, 10 mesh |

4.75 ~ 2.00 mm |

suitable for samples with larger particles such as soybeans and mung beans |

|

Coffee beans |

4 mesh, 6 mesh, 8 mesh |

4.75 ~ 2.36 mm |

sorting broken beans, whole beans, etc. |

|

Grain powder |

40 mesh, 60 mesh, 80 mesh, 100 mesh |

0.425 ~ 0.15 mm |

fine screening of flour and cereal powder |

1. Agricultural seed quality testing

Seed companies need to evaluate the physical properties of seed particles when breeding or selling grain seeds such as wheat, corn, and rice. Use 10 mesh to 30 mesh sieves to screen wheat or rice and distinguish between complete seeds and solid seed particles. Through particle size distribution analysis, judge seed consistency to ensure germination rate and planting quality. Detected (such as fragments, deformation), use 4 mesh to instantly produce large particles of debris.

2. Food processing quality control

Flour mills or food processing companies conduct particle size analysis of wheat, corn and other grains for grinding control. Use 8-20 mesh screens for wheat raw grains to evaluate grain size distribution and optimize milling processes. Use 40-200 mesh screens for finished flour to test powder fineness. Screen corn flour to separate coarse grains (>1mm) from fine powder (<0.25mm) for different foods (such as corn noodles).

3. Grain Processing Technology Optimization

Grain processing plants (such as rice finishing or oatmeal production) need to optimize crushing, milling or grading processes. In rice processing, use 10-40 mesh screens to separate whole rice grains and broken rice to evaluate rice mill performance. In oatmeal, 20-60 mesh screens are used for production grading to ensure uniform flake particles for ready-to-eat products.

4. Agricultural Research and Experimental Analysis

Colleges or research institutions study grain variety improvement, characterization or processing performance. Study the effect of wheat variety particle size on dough properties, use 30-100 mesh screens to analyze the water absorption and baking performance of flours of different particle sizes. Detect the particle breakage rate of corn in the instantaneous process, use 4-mesh to 20-mesh screens to evaluate the impact of instantaneous conditions on quality.

5. Import and export grain quality inspection

Customs or quality inspection agencies conduct detailed and meticulous inspections on imported grains (such as soybeans and corn). Use 4-mesh to 10-mesh screens to detect whether there are large particles (such as stones) mixed in the soybean batch. Screen imported wheat, 20-mesh to 60-mesh screens to evaluate the broken grain ratio and determine whether it meets food grade standards. For granular powder samples, use 100-mesh to 200-mesh screens to detect trace or additives.

Stainless steel grain granule test sieve for lab used in the laboratory is an important tool for analyzing grain particle size distribution, screening impurities or quality control. Through precise screening mesh (such as 4-200 mesh), the particle size distribution, overall content and processing characteristics of grain particles can be effectively analyzed, providing reliable support for agricultural production and food industry. If you need a recommended screening solution or supplier for a specific grain (such as wheat or corn), please provide more details and we can further design suggestions!

What is the wet sieving process?

Wet sieving process is a sieving process assisted by a liquid (usually water or a solution containing a dispersant) to more effectively...

Fines content tester can be defined as an instrument used to quantitatively determine the content of fines powder components of a specific fineness...

Micro silica powder particle size analysis test sieve

Micro silica powder, also known as silica fume, is an ultrafine active silica material with a very small particle size, usually between 0.1-0.3 microns, which...

Agricultural gruesos Test sieves

Agricultural gruesos test sieves are experimental equipment used for particle size analysis, grading and testing of agricultural soil, gruesos...

Stainless steel frame and woven cloth

The test sieve is a laboratory equipment used for particle size analysis. Its core components usually include a stainless steel frame and woven cloth (also called a sieve)...

Test sieve shaker for seed analysis

Test sieve shaker for seed analysis is an important equipment for separating and grading seeds in seed analysis, and is widely used in agricultural scientific research...

May 07, 2025

Stainless Steel Grain Granule Test Sieve for Lab

Stainless steel grain granule test sieve for lab is a key analytical tool. Through different mesh siz...

May 06, 2025

Test sieve shaker for seed analysis

The test sieve shaker for seed analysis is an important seed analysis equipment, widely used in agric...

Apr 30, 2025

Laboratory Special Fine Powder Screening Equipment

Laboratory special fine powder screening equipment is especially suitable for precise particle size c...

Apr 29, 2025

Resemary Chemical Reagent Standard Test Sieve

Rosemary Chemical Reagent Standard Test Sieves is a device dedicated to analyzing and grading rosemar...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap