![[field:title/]](/uploads/250401/2-2504011116054L.jpg)

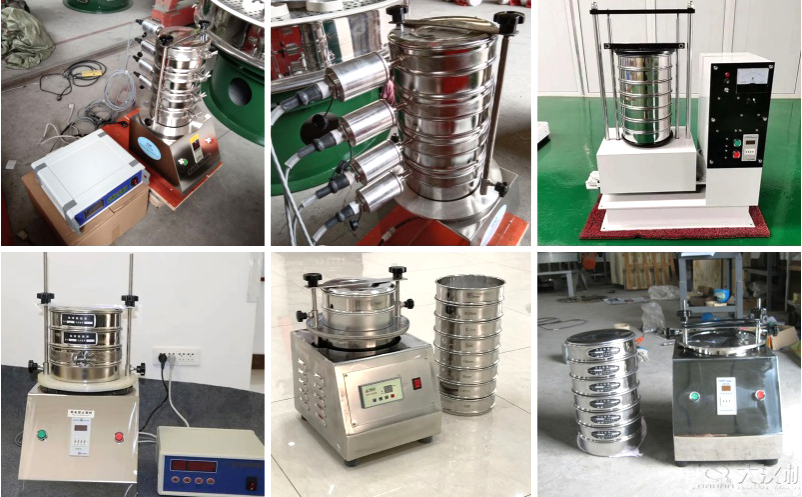

Stainless steel sieve shaker is a kind of equipment used for material screening, filtering and grading. It is made of stainless steel and has the characteristics of corrosion resistance, high temperature resistance and easy cleaning.

Sieve diameter:75mm, 100mm, 200mm, 300mm, 400mm, 500mm

Measuring range:20µm-125mm

Feeding amount:200g

Vibration frequency:1440times/min

Noise:less than50dB

Mesh size:2.36-0.02

Application scenario:Stainless steel test sieves are widely used in laboratory sampling and testing, and can also be used for screening and particle size detection of granular materials in industries such as abrasives, geotechnical engineering, metallurgy, pharmacopoeia, chemical building materials, etc.

Stainless steel sieve shaker is a kind of screening equipment made of stainless steel, specially used for screening and grading of granular materials. It is widely used in industries with high hygiene requirements such as food, medicine, and chemical industry. Stainless steel has the advantages of corrosion resistance, easy cleaning, non-toxic and harmless, which can effectively ensure the purity and safety of materials.

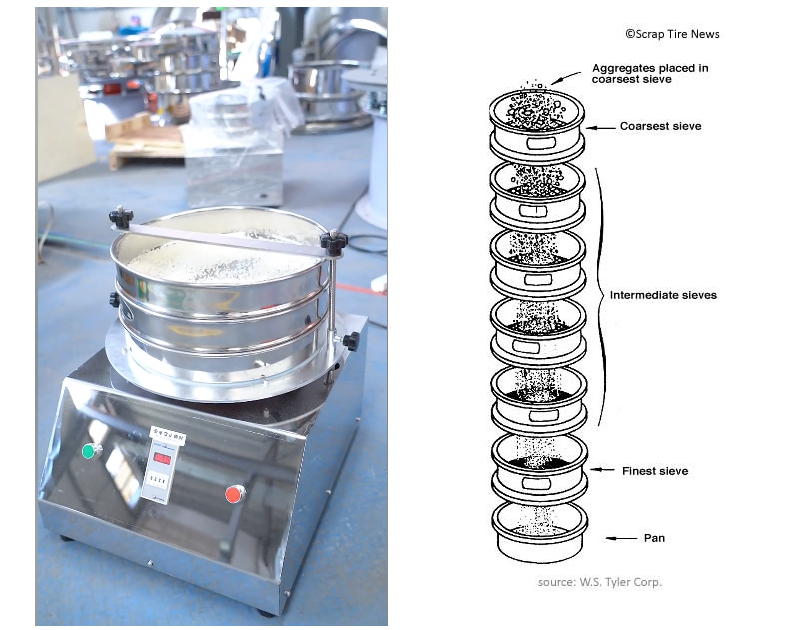

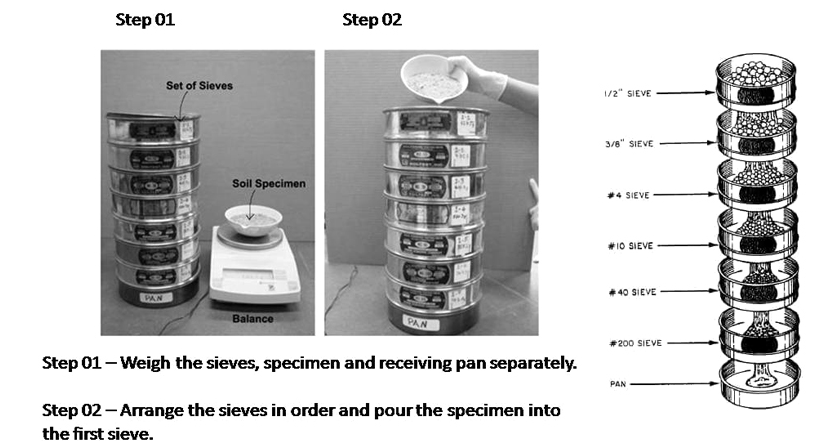

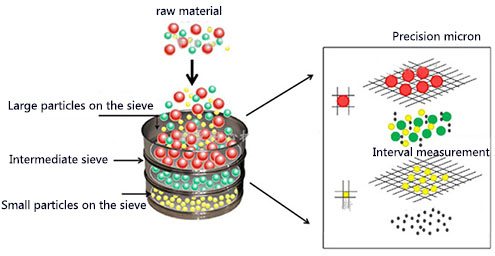

stainless steel sieve shaker mainly uses the high-frequency vibration generated by the vibration motor or exciter to make the screen frame and screen do reciprocating or circular motion. Under the action of vibration, the material constantly jumps, rolls and slides on the screen. The material particles smaller than the screen aperture will fall through the screen aperture to the lower layer or collection container, while the material particles larger than the screen aperture will be retained on the screen, thus realizing the graded screening of materials according to particle size.

Material: Usually 304 or 316 stainless steel is used, which has good corrosion resistance and wear resistance.

Screening accuracy: Screens of different mesh sizes can be selected according to needs, with high screening accuracy.

Structural design: The equipment has a compact structure, is easy to disassemble and clean, and meets hygiene standards.

Applicability: It is suitable for screening dry and wet materials, and can handle a variety of materials such as powders, particles, and liquids.

Automation level: Some equipment is equipped with vibration motors or ultrasonic devices to improve screening efficiency and accuracy.

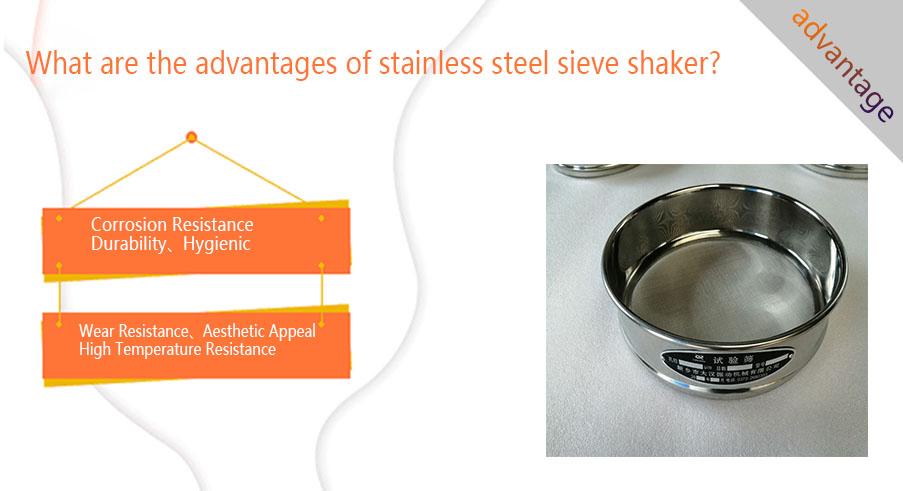

1、Corrosion Resistance: Stainless steel is highly resistant to corrosion, making it suitable for use in various industrial and laboratory environments where exposure to moisture or corrosive substances is common.

2、Durability: Stainless steel is a robust material that can withstand heavy use and harsh conditions. This durability ensures that the sieve shaker can maintain its performance over an extended period.

3、Hygienic: The smooth surface of stainless steel makes it hygienic and prevents the accumulation of bacteria, making it suitable for applications where cleanliness is a priority.

4、Wear Resistance: Stainless steel is resistant to wear and abrasion, ensuring that the sieve shaker maintains its integrity and performance even after prolonged use.

5、Aesthetic Appeal: Stainless steel has a modern and sleek appearance, which can enhance the overall look of the equipment and the workspace.

6、High Temperature Resistance: Stainless steel can withstand high temperatures, making it suitable for applications where heat is involved.

1. Screening and grading of granular materials: stainless steel sieve shakers are often used in the screening and grading process of granular materials. Through the screening machine, the granular materials can be divided into different levels according to their size to meet the production needs of different particle size requirements.

2. Removal of impurities: In industrial production, granular materials are often mixed with impurities. stainless steel sieve shakeres can effectively remove these impurities and improve the quality and purity of products.

3. Screening of powdered materials: For powdered materials, stainless steel sieve shakers can screen them according to different particle sizes for grading and screening in the production process.

4. Drying of granular materials: In some processes, stainless steel sieve shakers can also be used for drying granular materials, removing moisture from the materials by vibration and other means.

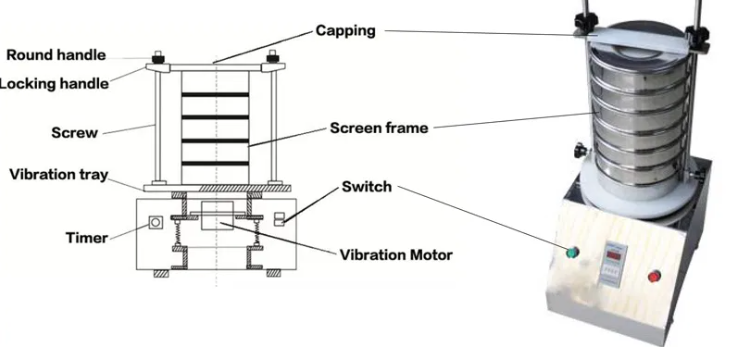

Screen frame: The screen frame is the main part of the stainless steel sieve shakers, usually welded from stainless steel plates, and has certain strength and stability.

Screen: The screen is the key component of the stainless steel sieve shakers, usually woven from stainless steel wire. The aperture size and shape of the screen will vary according to different screening requirements and the characteristics of the granular material.

Vibration device: Stainless steel sieve shakers is usually equipped with a vibration device, which allows the granular material to be screened on the screen through vibration to improve the screening efficiency.

Support structure: The support structure is used to support the stable operation of the entire stainless steel sieve shakers, and is usually also made of stainless steel.

Feed inlet and discharge port: The feed inlet and discharge port are used for the input and output of granular materials, and are usually designed at appropriate locations of the stainless steel sieve shakers to facilitate the entry and exit of materials.

Motor and control system: Stainless steel sieve shakers is usually equipped with a motor and control system to drive the vibration device and control the screening process to ensure the normal operation of the equipment.

1、Food industry: used for screening flour, starch, milk powder, powdered sugar, condiments, tea and other materials, removing impurities and grading to ensure the quality and taste of food.

2、Pharmaceutical industry: screening of drug particles, powders, etc. to ensure uniform particle size of drugs, in line with production process and quality standards, while removing foreign matter to ensure the safety and effectiveness of drugs.

3、Chemical industry: widely used in screening of various chemical raw materials, intermediates, and finished products, such as plastic particles, rubber powder, pigments, dyes, fertilizers, etc., to achieve particle size grading and impurity removal of materials, and provide high-quality raw materials and products for chemical production.

The price of a stainless steel sieve shaker will vary depending on a number of factors, ranging from a few hundred dollars to several thousand dollars, depending on the specifications and quality of the equipment. To obtain an accurate price quote, it is recommended to contact the DAHAN supplier or manufacturer directly. We can provide you with detailed pricing information based on your specific requirements.

Stainless steel sieve shakers play an important role in industrial production, helping to improve production efficiency, ensure product quality, and meet the needs of different industries for particle material screening. If you have more questions or need further information about stainless steel sieve shakers or other related topics, please feel free to let me know.

Five Advantages of Rotap Sieve Shaker

Rotap Sieve Shaker is mainly composed of machine base, sieve and transmission mechanism. It can be equipped with special fixtures, which can be used to clamp 200 test sieves, as wel...

Slap Type Test Sieve is mainly used in laboratories within universities/research institutes/enterprises, with standard test sieves for particle size analysis and detection of granul...

Stainless steel corn grits test sieve

Stainless steel corn grits test sieve is a screening device specially used for particle size analysis and quality control, and is widely used in food, chemical, pharmaceutical and o...

Laboratory Lactose Stainless Steel Test Sieve

Laboratory lactose stainless steel test sieve is a device used to accurately determine the size distribution of lactose particles. It is often used for laboratory particle analysis ...

Industrial Ultrasonic Metal Powder Test Sieve

Industrial ultrasonic metal powder test sieve is mainly used in laboratories or small batch production to analyze and classify fine particle materials such as metal powder and alloy...

Vitamin powder slapping screen

Vitamin powder slapping screen is a device used to sieve vitamin powder. It achieves sieving through vibration and slapping action. It is often used to remove impurities, grade part...

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap