![[field:title/]](/uploads/250928/1-25092Q62410547.jpg)

Sugar Test Sieve is a kind of experimental equipment specially used to measure the particle size distribution of sugar products. It classifies sugar products according to particle size through sieving method, so as to evaluate their quality and suitability.

1. Automatically shut down at a fixed time to ensure test repeatability

2. A granule can be precisely separated into 2 to 7 particle segments at the same time

3. Sugar content test sieves are widely used in the food industry, sugar industry, laboratory research and other fields

Port: Any port in China (Mainland)or as you need.

|

Quantity(sets) |

1-2 |

>2 |

|

Delivery time(days) |

5 |

To be negotiated |

Sugar test sieve are often used with standard sieve sets in conjunction with mechanical vibrating screens and other devices. The screening particle size varies depending on the type of sugar and testing standards: refined sugars commonly use apertures of 850μm, 600μm, 500μm, and 355μm. White sugar testing generally covers a range of 0.28mm to 2.5mm. Powdered sugar screening can be refined to 212μm or even smaller. In terms of output, experimental equipment can process approximately 200g of sample at a time, and screening takes 10-20 minutes. Industrial-grade sugar sieves have higher outputs. High-flow screens can increase sugar production by 150%-170% compared to standard screens. Some vibrating screening equipment can reach over 100 tons per hour, which is affected by the screen aperture, porosity, vibration parameters, and sugar condition.

Sugar Test Sieve usually consists of a set of standard sieves, sieve frames, chassis and covers, which separate sugar products by particle size through mechanical vibration or manual operation. Its core function is to measure the particle size distribution of sugar products to ensure that they meet production or use requirements.

First, place the sugar product to be tested into the upper sieve to complete the loading. Then, mechanical vibration is used to make the sugar product move on the sieve, allowing fine sugar particles to pass through the sieve and fall into the lower layer, while coarse sugar particles remain on the sieve to achieve screening. Then, the different apertures of each sieve are used to classify the sugar products according to particle size. Finally, the sugar products on each sieve are taken out, weighed, and the particle size distribution is calculated to complete the weighing.

| Parameter name | Parameter range/example value | Remarks |

|---|---|---|

| Sieve aperture | 20 mesh~500 mesh | Select according to the particle size of sugar products |

| Sieve frame diameter | 100mm, 200mm, 300mm | The commonly used diameter in the laboratory is 200mm |

| Number of screening layers | 1~8 layers | Select according to the particle size classification requirements |

| Vibration frequency | 50Hz~60Hz | Used for mechanical vibration screening |

| Sieving time | 5min~15min | Determined according to the sample amount and particle size distribution |

| Material | Stainless steel, brass, plastic | Stainless steel is most commonly used, corrosion-resistant and easy to clean |

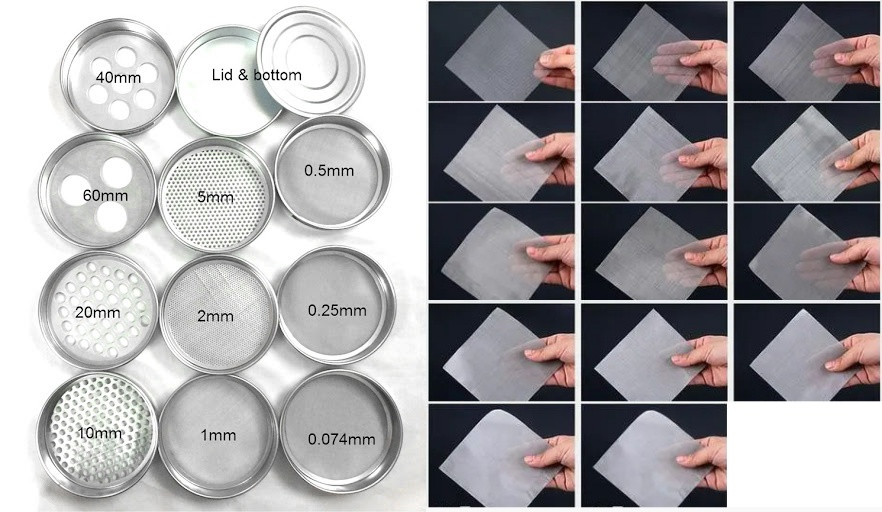

Mesh size: The mesh size of the test sieve is usually expressed in mesh or millimeter (mm). Common mesh sizes include 20 mesh (0.84 mm), 40 mesh (0.42 mm), 60 mesh (0.25 mm), 80 mesh (0.18 mm), 100 mesh (0.15 mm), etc.

Mesh specifications: The mesh of the test sieve usually uses standard specifications. There will be some slight differences in different standard specifications, but they usually provide a series of standardized mesh apertures and wire diameters.

Sieve frame size: The sieve frame of the test sieve usually has standard sizes, such as a round sieve frame with a diameter of 200 mm or 300 mm, or a square sieve frame with a side length of 200 mm or 300 mm.

| Shape | Diameter | Effective screen surface diameter | Height | |

|---|---|---|---|---|

| Min | Max | |||

| Round hole | 75mm | 75mm | 65mm | 25mm |

| 200mm | 200mm | 185mm | 25mm, 50mm | |

| 300mm | 300mm | 275mm | 75mm | |

| Square hole | 300mm | 300mm | 75mm | |

| Material type | Picture | features | disadvantages | applicable scenarios |

|---|---|---|---|---|

| Stainless steel sieve |

|

made of stainless steel (such as 304 or 316 stainless steel) | higher cost and heavier weight | scenarios that require high-precision screening, such as the sugar industry, food industry, and laboratory research |

| Brass sieve |

|

made of brass, with certain wear resistance and corrosion resistance | easy to oxidize, short service life | small-scale production or limited budget scenarios |

| Nylon sieve |

|

made of nylon material, light and not easy to rust | poor wear resistance, easy to deform, not suitable for high-precision screening | temporary screening or scenarios with low precision requirements |

| Alloy screen |

|

Made of special alloys (such as high manganese steel), with extremely high wear resistance and corrosion resistance | High cost, heavy weight | High-precision screening or scenes with extremely high wear resistance requirements. |

The screen is made of stainless steel or brass, with standard aperture sizes such as 20, 40, and 60 mesh. The screen frame, which secures the screen, is typically made of stainless steel or plastic. The bottom tray collects the powdered sugar after it passes through the finest sieve. A cover prevents splashing during the screening process. A vibrating device automates the screening process, improving efficiency and accuracy.

Sugar Test Sieve is used in food and beverage, agriculture, scientific research laboratories, and traditional Chinese medicine preparations to assist in impurity filtration, maturity determination, sample analysis, and drug quality control.

Food and beverage industry: In the process of fruit juice production, it is necessary to first use a sieve to filter out solid impurities such as pulp and peel, and then use a saccharimeter to measure the sugar content of the juice. Through sieves with different apertures, sugar test sieve can separate pulp particles of different sizes.

Agricultural field: In the process of fruit and vegetable cultivation, the maturity and quality of fruits or vegetables can be judged by measuring their sugar content. By measuring the sugar content of different varieties of fruits and vegetables through sugar test sieve, varieties with higher sugar content can be screened out for breeding and promotion.

Scientific research laboratory: In scientific research laboratories, sugar test sieve can be used to analyze various samples containing sugar, such as plant extracts, fermentation broth, etc. Through screening and sugar content measurement, the distribution, content and properties of sugar can be studied.

Traditional Chinese medicine preparations: In the traditional Chinese medicine preparation industry, some traditional Chinese medicine ingredients contain sugar, and sugar content needs to be tested through sugar test sieve to ensure the quality of the medicine.

| Number of mesh | mesh diameter (mm) | number of mesh | mesh diameter (mm) | number of mesh | mesh diameter (mm) |

|---|---|---|---|---|---|

| 2 mesh | 12.5 | 45 mesh | 0.4 | 220 mesh | 0.065 |

| 3 mesh | 8 | 50 mesh | 0.355 | 240 mesh | 0.063 |

| 4 mesh | 6 | 55 mesh | 0.315 | 250 mesh | 0.061 |

| 5 mesh | 6 | 60 mesh | 0.28 | 280 mesh | 0.055 |

| 6 mesh | 4 | 65 mesh | 0.25 | 300 mesh | 0.050 |

| 8 mesh | 3 | 70 mesh | 0.224 | 320 mesh | 0.045 |

| 10 mesh | 2 | 75 mesh | 0.2 | 325 mesh | 0.043 |

| 12 mesh | 1.6 | 80 mesh | 0.18 | 340 mesh | 0.041 |

| 14 mesh | 1.43 | 90 mesh | 0.16 | 360 mesh | 0.040 |

| 16 mesh | 1.25 | 100 mesh | 0.154 | 400 mesh | 0.0385 |

| 18 mesh | 1 | 110 mesh | 0.15 | 500 mesh | 0.0308 |

| 20 mesh | 0.9 | 120 mesh | 0.125 | 600 mesh | 0.026 |

| 24 mesh | 0.8 | 130 mesh | 0.112 | 800 mesh | 0.022 |

| 26 mesh | 0.71 | 140 mesh | 0.105 | 900 mesh | 0.020 |

| 28 mesh | 0.68 | 150 mesh | 0.100 | 1000 mesh | 0.015 |

| 30 mesh | 0.6 | 160 mesh | 0.096 | 1800 mesh | 0.010 |

| 32 mesh | 0.58 | 180 mesh | 0.09 | 2000 mesh | 0.008 |

| 35 mesh | 0.50 | 190 mesh | 0.08 | 2300 mesh | 0.005 |

| 40 mesh | 0.45 | 200 mesh | 0.074 | 2800 mesh | 0.003 |

The steps for testing sugar content using the Sugar Test Sieve typically include five routine steps: preparing the sample, preparing the juice, using the sugar test sieve, determining the sugar content, and interpreting the results.

Prepare the sample: Select fresh fruit or vegetable samples, wash and remove the skin, and keep the sample intact.

Prepare the juice: Chop or squeeze the sample to release the juice, and prepare the juice sample to be tested.

Use the sugar test sieve: Place the sugar test sieve on the container, pour the juice sample to be tested, and gently shake or press to make the juice pass through the sieve meshs.

Measure the sugar content: The juice flowing out through the sieve meshs contains plant cells, and the sugar molecules are small. The sweetness of the sample can be judged by measuring the sugar content in these juices.

Read the results: According to the test results, the sugar content of the sample can be judged.

The Sugar Test Sieve can process various types of sugar, including granulated sugar, brown sugar, rock sugar, and fructose. During operation, the sugar to be sieved is evenly placed on the top sieve, and sieves of different mesh sizes are stacked according to the desired particle size. After starting the sieve, the sugar passes through the sieve layer by layer under vibration or shaking. The finest sugar is discharged from the bottom outlet, while coarser particles remain on the upper sieves. Different types of sugar require different mesh sizes depending on the intended use; for example, granulated sugar commonly uses 40–80 mesh, brown sugar and rock sugar use 20–60 mesh, and fructose uses 60 mesh or higher to ensure uniform particle size and stable sieving results.

The disadvantages of the Sugar Test Sieve are its limited accuracy and susceptibility to temperature, humidity, and operating methods, leading to unstable results. Sieve aperture size and sample variations can also affect the measurement, requiring multiple repetitions.

Applicable products have limitations: The design and aperture size of sugar test sieve may not be suitable for all types of agricultural products, and some samples with special shapes or high viscosity may not be screened effectively.

There is a problem of insufficient screening accuracy: Sugar test sieve may have insufficient screening accuracy due to factors such as the screen material, aperture size, or vibration frequency during the screening process. This may make the screening results inaccurate and fail to accurately reflect the true sugar content of the substance being tested.

Improper sample handling: Before sugar test sieve is used, the sample needs to be properly handled. If the sample is not handled properly, such as insufficient mixing, uneven sampling, etc., it may affect the accuracy of the screening results.

Error in sugar content particle size distribution: Since sugar products are prone to moisture absorption or agglomeration, it may cause errors in particle size distribution measurement. Inaccurate measurement results affect quality control. Sugar test sieves dry sugar products before sieving or use anti-caking agents.

Choose the sieve according to the particle size range: the sieve aperture should be selected according to the particle size distribution of the sugar product.

Choose the sieve frame diameter according to the sample volume: choose a sieve frame with a larger diameter when the sample volume is large.

Choose manual or mechanical vibration according to needs: mechanical vibration screening efficiency is higher and suitable for large-scale testing.

Consider the material: stainless steel is corrosion-resistant, easy to clean, and suitable for long-term use.

Our factory can customize various models of laboratory sieves, such as DH-300T, DH-400T, and DH-500T, according to customers' screening capacity requirements and sieve sizes, to meet the needs of different experimental and production scales. Each piece of equipment can be optimized for material characteristics, including sieve material, vibration frequency, and sieve surface structure, to ensure screening efficiency and accuracy. In addition, we provide trial operation services, using specific materials provided by the customer to conduct actual screening tests, helping to determine the optimal screening particle size and the most suitable equipment model.

Five Advantages of Rotap Sieve Shaker

Rotap Sieve Shaker is mainly composed of machine base, sieve and transmission mechanism. It can be equipped with special fixtures, which can be used to clamp 200 test sieves, as wel...

Slap Type Test Sieve is mainly used in laboratories within universities/research institutes/enterprises, with standard test sieves for particle size analysis and detection of granul...

Test sieve sugar powder size detection

Test sieve sugar powder size detection is a key method for evaluating the fineness of sugar powder and its particle distribution...

Soil sieve analysis is a soil particle size determination method based on the principle of mechanical separation...

Juice Powder Ultrasonic Sieve test

The ultrasonic sieve test for juice powder is a fine screening equipment designed for delicate, moisture-absorbing...

Test sieves for reliable sieve analysis

Test sieves for reliable sieve analysis use high-precision stainless steel test sieves with mesh conforming to international standards, ensuring accurate and reliable particle size ...

Laboratory woven wire mesh sieves

Laboratory woven wire mesh sieves are screening tools made of 250 mm stainless steel frame and precision woven wire mesh. The high quality of the equipment ensures reliable screenin...

Sieve Mesh is a metal or non-metal device used to separate materials. Its mesh count refers to the number of holes per square inch. It sorts powders by particle size through vibrati...

For Laboratory Sieves Price ranges from $100 to $500 USD, and the price varies depending on the sieve diameter, mesh range, material, and quantity.......

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap