Monday April-28 2025 16:07:25

Test sieve is designed for particle size testing of chemical powders and oil mixtures, and is suitable for fine screening and analysis in laboratories. It uses a stainless steel sieve frame with a diameter of Φ200mm, and the mesh range is from 20 mesh to 500 mesh (customizable according to needs), which can accurately separate particles and liquids of different particle sizes. The vibration frequency is adjustable, and the sieve hole size ranges from 0.074mm to 0.85mm. The whole machine is mostly made of stainless steel, which is suitable for processing chemical powders and oil samples with certain viscosity or corrosiveness. Through vibration or rotational motion, the powder oil is graded and the particle distribution is accurately determined, providing a basis for product quality control.

The working principle of the test sieve for testing chemicals powders oils is based on mechanical vibration or rotational motion to achieve particle classification.

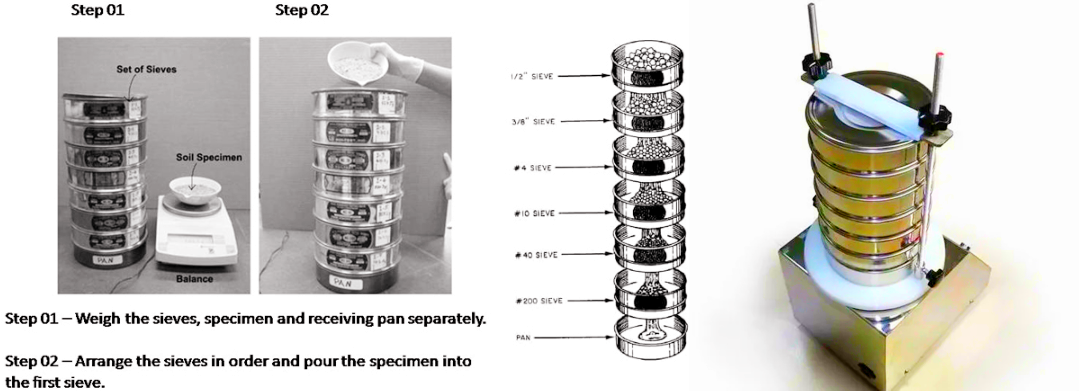

① Position the powder oil sample on the sieve

② After starting the equipment, the vibration motor or rotating mechanism produces regular vibration or rotation, allowing the particles to pass through the sieve holes according to size.

③ Particles smaller than the sieve holes pass through, and particles larger than the sieve holes remain on the sieve, thereby achieving particle size separation.

④ After the sieving is completed, collect the particles in each layer, analyze the sieving distribution, and provide data support for pollutant quality control.

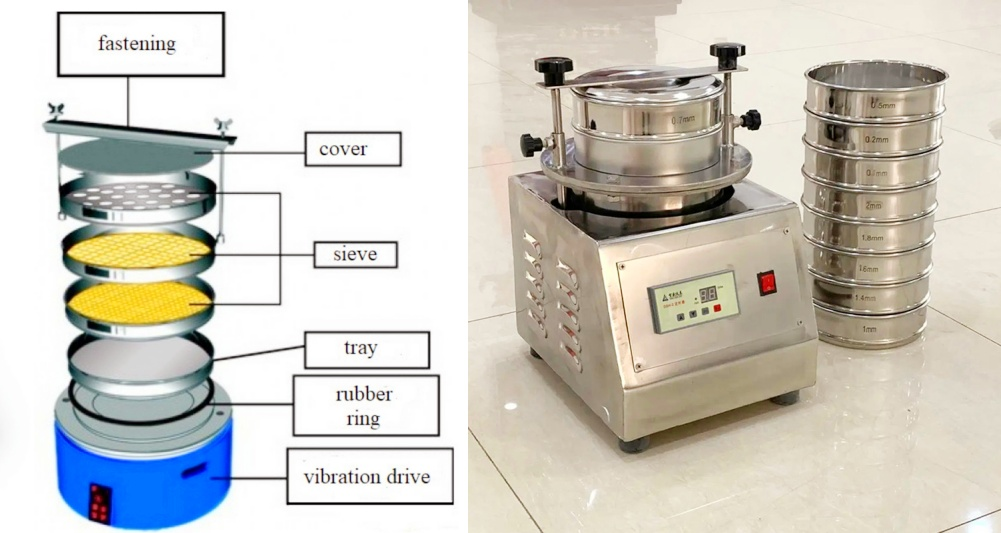

The structure of oils mainly includes the following parts:

Sieve frame: usually round, 200mm in diameter, mostly made of stainless steel, corrosion-resistant and reinforced, used to fix the sieve and carry the sample.

Sieve: core component, the mesh size is determined by the mesh size (20-200 mesh, aperture 0.074-0.85mm), the material is stainless steel or stainless steel, which determines the particle classification accuracy.

Structure and cover: the structure collects fine particles passing through the sieve, and the cover prevents the sample from splashing and keeps the sieving process clean.

Drive device: includes a vibration motor or a rotating mechanism, which generates vibration or rotational motion, drives the particles through the sieve, and the vibration frequency and amplitude are adjustable.

Support structure: fixes the entire sieve body to ensure stable operation, and some models support the device to reduce noise.

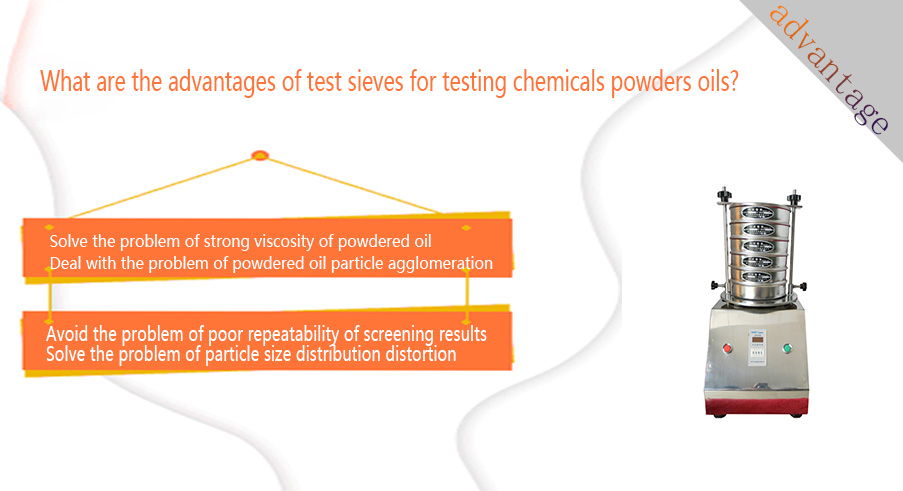

Solve the problem of strong viscosity of powdered oil: Chemical powdered oil often contains oily components or high-viscosity additives, which cause particles to adhere to the screen during screening, block the screen holes, and reduce screening efficiency. The test sieve uses high-frequency vibration (20-40kHz) to produce a small amplitude on the screen surface to prevent particle powder.

Deal with the problem of powdered oil particle agglomeration: The fine particles in the powdered oil are easily agglomerated due to static electricity or van der Waals force, forming false particles, causing the screening results to become a real particle distribution. Use gradient test sieves (3-8 layers, decreasing mesh number) to directly pass through the step screening to reduce the probability of agglomerated particles.

Avoid the problem of poor repeatability of screening results: The unevenness of powdered oil (such as uneven oil distribution) or improper operation may cause fluctuations in screening results and affect data reliability. Formulate a unified screening procedure, fix the vibration time, sample amount (200-500g) and screen cleaning frequency to ensure consistent experimental conditions.

Solve the problem of particle size distribution distortion: Differences in oil viscosity lead to different particle settling speeds. Using ethanol or base oil as the medium, isokinetic sedimentation is achieved by matching the medium viscosity. The coarse screen section (>100μm) uses high amplitude (2-3mm) to promote the separation of large particles, and the fine screen section (<50μm) switches to low amplitude (0.5-1mm) to avoid over-screening.

|

Project |

Parameter description |

Project |

Parameter description |

|

Sieve frame diameter |

Φ200mm |

Sieve mesh range |

20 mesh~500 mesh (customizable according to demand) |

|

Number of layers |

1~8 layers optional |

Material |

Stainless steel 304 (optional 316L) |

|

Vibration frequency |

1500~3000 times/minute |

Amplitude |

0~2mm (adjustable) |

|

Motor power |

0.12kW~0.18kW |

Power supply requirements |

AC220V 50Hz (special voltage can be customized) |

|

Timing function |

Supports 1~99 minutes adjustable |

Applicable materials |

Chemical powders, oil-containing mixtures |

|

Total machine weight |

About 25kg~40kg (slightly different according to the number of layers) |

Protective design |

Equipped with a protective cover to prevent sample splashing |

The application of test sieves in the field of chemical powder oils runs through the entire process of research and development, production and quality control. Its core value lies in optimizing product performance and ensuring process stability through particle size distribution analysis.

Quality control and product grading: In the production of chemical powder oils, particle size distribution directly affects product performance. Test sieves for testing chemicals powders oils (Φ200mm, 20-200 mesh) are used to detect whether the particle size of finished or semi-finished products meets the standard.

Production process optimization: Powder oil production involves processes such as grinding and spray drying, and test sieves are used to monitor process effects. For example, when producing powdered resins (for oily coatings), the ground samples are tested through test sieves to confirm whether the target particle size is reached (such as 80% of the particles are less than 75μm).

Environmental and safety testing: The possible consequences of chemical powder oils during transportation or use, test sieves are used to assess emergency situations. Chemical plants test suspended particles generated during the loading and unloading of powder oils, and use test sieves to separate PM10 (less than 10μm) or PM2.5 (less than 2.5μm) particles.

Recycling and reuse: Test sieves are used to separate reusable particles. For example, waste catalyst powder (containing precious metals) is graded through test sieves to screen out particles of a specific particle size (such as 50-100μm) for reprocessing.

The mesh size of test sieves for testing chemicals powders oils can be flexibly selected according to the test requirements. Common specifications include but are not limited to 20 mesh, 40 mesh, 60 mesh, 80 mesh, 100 mesh, etc. These sieves with different mesh sizes can effectively separate powders of different particle size ranges and provide accurate data for analyzing the particle composition of chemical powder oils. The test sieve is compact and easy to operate, and is an indispensable tool in quality control.

What is the wet sieving process?

Wet sieving process is a sieving process assisted by a liquid (usually water or a solution containing a dispersant) to more effectively...

Fines content tester can be defined as an instrument used to quantitatively determine the content of fines powder components of a specific fineness...

Micro silica powder particle size analysis test sieve

Micro silica powder, also known as silica fume, is an ultrafine active silica material with a very small particle size, usually between 0.1-0.3 microns, which...

Agricultural gruesos Test sieves

Agricultural gruesos test sieves are experimental equipment used for particle size analysis, grading and testing of agricultural soil, gruesos...

Stainless steel frame and woven cloth

The test sieve is a laboratory equipment used for particle size analysis. Its core components usually include a stainless steel frame and woven cloth (also called a sieve)...

Introduction and related specifications of standard test sieves

Standard test sieves are key tools for particle size analysis and follow standards such as ISO3310-1 or ASTME11. The core lies in the precise mesh size, which...

Apr 28, 2025

Test Sieves for Testing Chemicals Powders Oils

The Φ200mm test sieve for testing chemical powder oil is specially designed for analyzing the partic...

Apr 26, 2025

Introduction and related specifications of standard test sieves

Standard test sieves are the core tools for particle size analysis. They are used to grade and detect...

Apr 25, 2025

Micro silica powder particle size analysis test sieve

The micro silica powder particle size analysis test sieve is a laboratory equipment designed specific...

Apr 25, 2025

Mineral analysis multi-layer slap sieve

Mineral analysis multi-layer slap sieve is a sieveing equipment specifically used for mineral particl...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap