Monday May-12 2025 16:06:41

Test sieve for cement fineness is often called cement fineness sieve or cement sieving sieve. It is a key experimental instrument for cement fineness testing. This sieve is mainly used to test the residue content larger than a certain particle size in cement particles and judge the fineness grade of cement. It is one of the important indicators for measuring the uniformity and grinding degree of cement particles.

In cement fineness detection, the test sieve for cement fineness is mainly divided into two categories: round hole sieve and square hole sieve. Its specifications are as follows:

Round hole sieve: round hole sieve commonly used for cement fineness detection, the sieve hole size is 0.080mm, corresponding to about 180 mesh. Due to the characteristics of the sieve hole shape of the round hole sieve, the way particles pass through the sieve hole during the screening process is different from that of the square hole sieve. It has a unique effect on the detection of cement particle fineness, but it is relatively less used in cement fineness detection.

Square hole sieve: It is a commonly used sieve for cement fineness detection. Common sieve hole sizes are 0.080mm and 0.045mm, corresponding to about 180 mesh and 325 mesh respectively. The sieve hole shape of the square hole sieve is more conducive to the accurate screening of cement particles according to size, which can more accurately reflect the fineness of cement and is widely used in cement production and quality control.

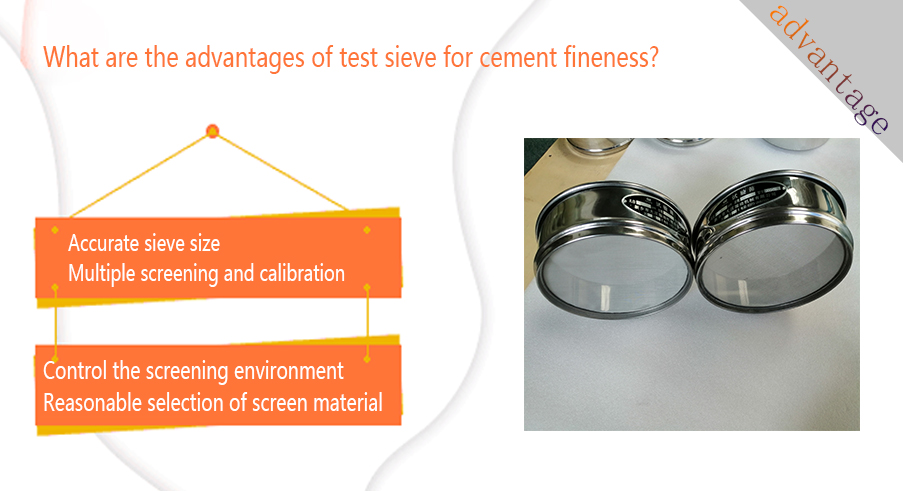

Accurate sieve size: The sieve size of the test sieve for cement fineness has strict standards and high-precision processing technology. For example, the common cement fineness test sieve sieve size is 45μm, 80μm, etc., and its size deviation is controlled within a very small range, which can accurately classify cement particles of different particle sizes, providing a basic guarantee for the accurate detection of cement fineness.

Multiple screening and calibration: When using the test sieve for cement fineness detection, multiple screening operations are usually performed, and the test sieve is calibrated regularly. Multiple screening allows cement particles to fully pass through the sieve holes and reduce the error caused by incomplete screening at one time. Regular calibration is to calibrate the test sieve by using standard particle materials.

Control the screening environment: Test sieve for cement fineness is usually used under relatively stable environmental conditions, such as controlling the temperature and humidity of the environment. Because when the ambient humidity is high, cement particles are prone to agglomeration due to the absorption of moisture. By controlling the ambient humidity within a suitable range, the phenomenon of particle agglomeration due to moisture can be reduced, ensuring the smooth progress of the screening process.

Reasonable selection of screen material: The detection screen usually uses a screen made of stainless steel and other materials. Its surface is smooth and not easily adhered to by cement particles, reducing the chance of screen hole clogging due to particle adsorption. Stainless steel has high strength and wear resistance, can withstand friction and impact during cement screening, is not easy to deform, and ensures the stability of the screen hole size.

|

Mesh number |

Sieve size |

Recommended use |

Description |

|

80 mesh |

≈180μm |

Coarse sieve |

Used to roughly separate larger particles, preliminary screening, less used |

|

100 mesh |

≈150μm |

Reserve sieve |

Applied to special cement or admixture materials, evaluate the content of extremely fine particles, suitable for high-performance concrete research |

|

200 mesh |

≈75μm |

Standard sieve |

Applied to specific types of cement or situations with higher fineness requirements, detect finer particles, suitable for studying the impact of cement performance |

|

325 mesh |

≈45μm |

High-precision detection (such as ultra-fine cement) |

Applied to conventional cement fineness detection, can effectively screen out coarse particles, suitable for most cement |

|

400 mesh |

≈38μm |

Special test |

Not used for routine testing, only for special scientific research or fine material testing |

Test sieve for cement fineness is mainly used to analyze and detect the particle size distribution of cement particles. It is an important tool for evaluating cement quality, predicting its strength properties and construction adaptability. In the cement production, inspection and construction links, fineness screens have a wide range of specific application scenarios.

1. Quality control in the cement production process:

Clinker needs to be ground to form cement with gelling ability. The fineness of grinding directly determines the performance of cement. The cement fineness detection screen regularly samples the ground cement and uses a standard sieve for screening to detect the content of coarse particles larger than the sieve size. This helps manufacturers monitor the operating status and efficiency of the grinding equipment in real time, ensure that the cement meets the specified fineness requirements, and avoid problems such as insufficient hydration and slow strength development due to over-coarse grinding.

2. Cement factory and on-site acceptance:

When cement products are completed and ready to leave the factory, strict quality inspections are required, including fineness testing. Similarly, when cement is transported to the construction site or ready-mixed concrete mixing plant, on-site acceptance is also required to ensure that the cement received meets the project requirements. Through screening testing, it can be verified whether the cement provided by the supplier meets the fineness index agreed in the contract to prevent the use of unqualified cement and affect the quality of the project.

3. Laboratory research and new product development:

Test sieve for cement fineness is also an important tool in the field of cement and related materials research and development. When comparing the performance differences of different types of cement, fineness is one of the important influencing factors. By sieving different cements with unified standards, the test sieve for cement fineness can quantify their fineness differences and conduct a comprehensive analysis in combination with other performance indicators.

4. Cement performance verification in specific application scenarios:

In some engineering projects with special requirements for cement performance, more specific or stricter requirements may be put forward for cement fineness. The production of high-strength concrete usually requires the use of cement with higher fineness to ensure that the cement particles can be more fully hydrated and form a denser structure. Test sieve for cement fineness can be used to verify whether the fineness of the cement used meets the design requirements of high-strength concrete.

Test sieve for cement fineness is an important step in evaluating cement quality. Commonly used test sieves include 325 mesh, 200 mesh and 100 mesh sieves. The 325 mesh sieve is the most commonly used standard and is suitable for routine fineness testing of most cements. It can effectively screen out coarse particles to ensure that the cement meets the design requirements.

For specific types of cement or situations where higher fineness is required, the 200 mesh sieve is recommended. It can detect finer particles and is suitable for studying the effect of cement fineness on concrete performance. The 100 mesh sieve is used for cement or admixtures with special requirements to evaluate the content of extremely fine particles to ensure its application in high-performance concrete.

By selecting the appropriate mesh number, construction and production units can better control the performance of cement and improve the quality and durability of construction projects.

What is the wet sieving process?

Wet sieving process is a sieving process assisted by a liquid (usually water or a solution containing a dispersant) to more effectively...

Fines content tester can be defined as an instrument used to quantitatively determine the content of fines powder components of a specific fineness...

Micro silica powder particle size analysis test sieve

Micro silica powder, also known as silica fume, is an ultrafine active silica material with a very small particle size, usually between 0.1-0.3 microns, which...

Agricultural gruesos Test sieves

Agricultural gruesos test sieves are experimental equipment used for particle size analysis, grading and testing of agricultural soil, gruesos...

Stainless steel frame and woven cloth

The test sieve is a laboratory equipment used for particle size analysis. Its core components usually include a stainless steel frame and woven cloth (also called a sieve)...

Test sieve for sand grading is a test device that separates sand particles by sieve hole size. It is used to analyze the particle grading and fineness modulus of sand.

May 12, 2025

Test sieve for cement fineness

Test sieve for cement fineness is a key tool for evaluating cement particle size distribution and gri...

May 10, 2025

The test sieve for sand grading is a device that uses mechanical vibration and multi-layer standard s...

May 09, 2025

Test sieve for soil analysis is a key tool for soil particle size distribution analysis. It grades so...

May 08, 2025

Herbal Powder Lab Sieve Shaker

The herbal powder lab sieve shaker is a laboratory equipment specially used for screening, impurity r...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap