Thursday May-15 2025 17:49:30

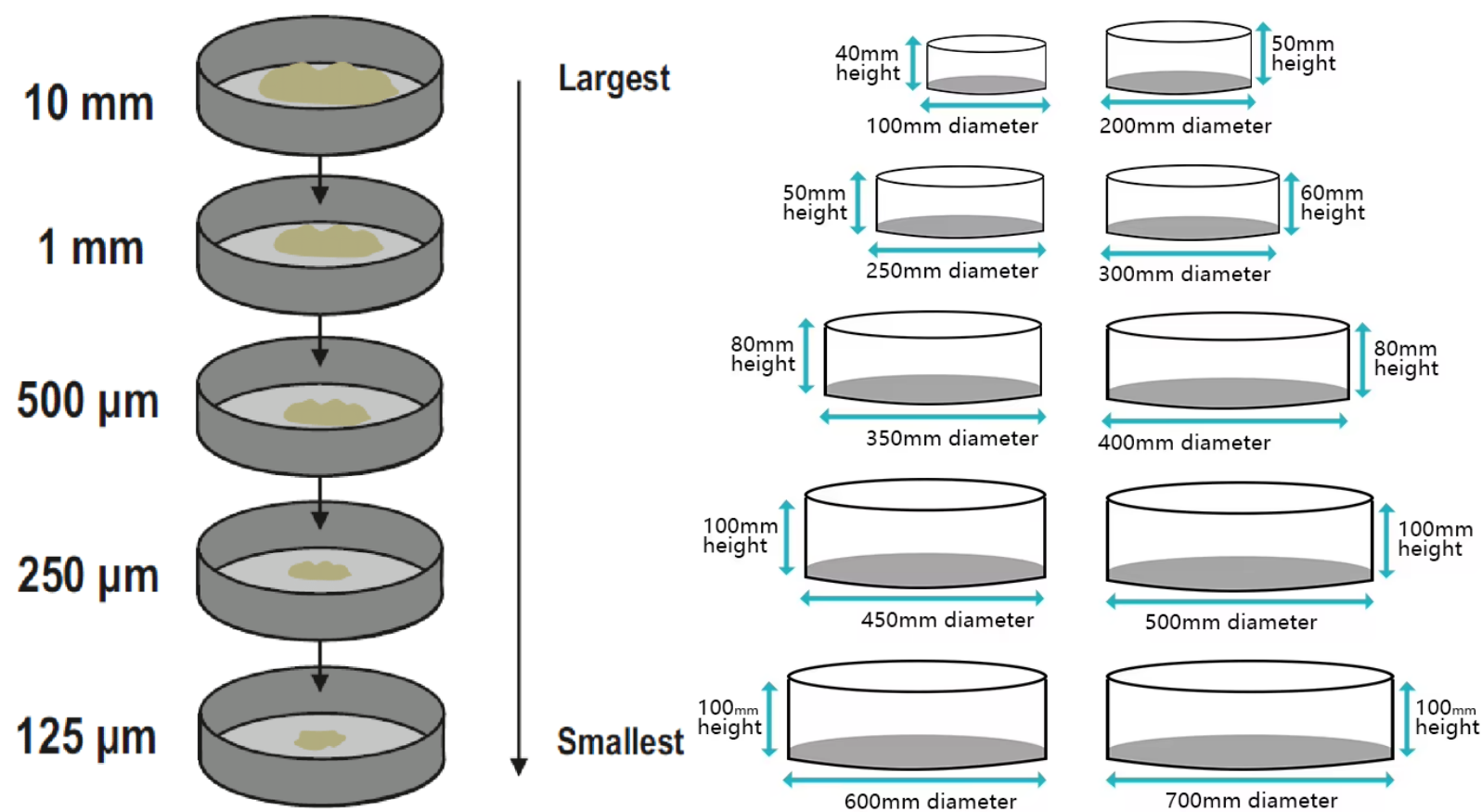

The test sieve for flour quality control is a key screening equipment in the flour production and testing process. It can grade and detect the coarseness and fineness of flour particles by accurately controlling the mesh number of the sieve. It is one of the core tools to ensure flour quality. Its core characteristics are reflected in the accuracy of the sieving mesh and the adaptability of flour quality control: commonly used sieving meshes include 60 mesh, 80 mesh, 100 mesh, 120 mesh, etc. (the larger the mesh, the finer the sieve hole).

① Detecting flour coarseness and fineness: by sieving flour samples on sieves of different specifications, flours of different particle sizes are separated, and the coarseness and fineness of flour grains are calculated according to the residual amount of the sieve, so as to determine whether the flour meets the corresponding grade standards or process requirements.

② Monitoring the flour processing process: During the flour processing process, the test sieve can be used to detect the flour after each process, and the changes in the size of flour particles can be found in time, so as to adjust the processing parameters and ensure the stability of flour quality.

③ Ensure the consistency of flour product quality: For flour production companies, using test sieves to control the quality of each batch of flour can ensure that different batches of flour are consistent in coarseness and fineness, and meet the needs of consumers.

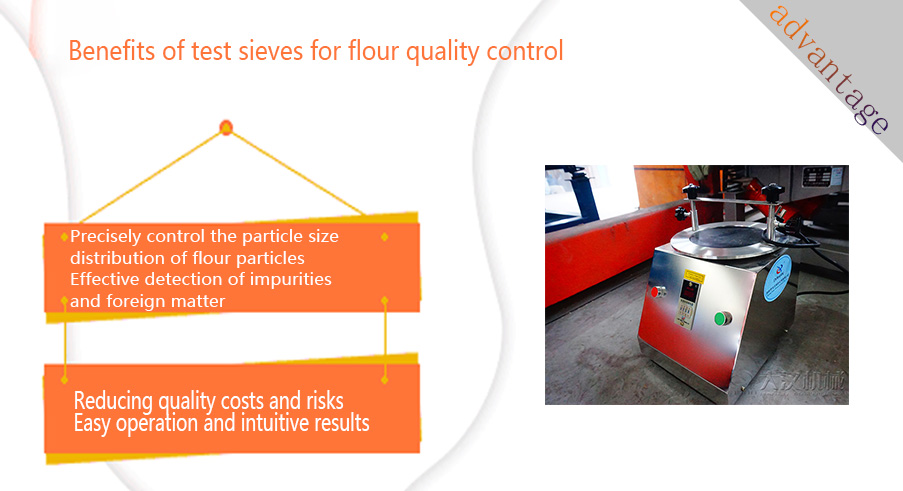

Precisely control the particle size distribution of flour particles: Through sieves with different apertures (such as 60 mesh, 80 mesh, etc.), the test sieve can accurately separate flour particles to ensure that the particle size meets specific product standards (such as coarser particles for bread flour and finer particles for cake flour). Uniform particle size distribution directly affects the water absorption, fermentation effect and taste of flour products.

Effective detection of impurities and foreign matter: Impurities may be mixed into flour during production and transportation, which not only affects the quality of flour, but also may cause safety risks. The sieve of the test sieve for flour quality control can intercept impurities larger than flour particles. Through the analysis of the residue after sieving, it can quickly detect whether the impurity content exceeds the standard and prevent unqualified products from entering the market.

Reducing quality costs and risks: Through online detection of the test sieve for flour quality control (such as real-time sampling and sieving during production), unqualified products can be found in time and the process can be adjusted to avoid the production of large quantities of unqualified products and reduce rework costs.

Easy operation and intuitive results: The operation process is simple, sample testing can be completed in a short time, and it is suitable for rapid quality monitoring at the production site. After sieving, flour particles or impurities of different particle sizes are directly retained in the corresponding sieve layer, without the need for complex instrument analysis, which is convenient for production personnel to adjust the process in time.

Flour type Application scenario Recommended mesh number Pass rate requirement Remarks

High-gluten flour Particle size analysis

(bread, noodles) 80 mesh, 100 mesh, 120 mesh 100 mesh≥80% Ensure moderate particles

Low-gluten flour Particle size analysis

(cake, biscuits) 140 mesh, 180 mesh, 200 mesh 180 mesh≥95% Ultra-fine particles required

Medium-gluten flour Particle size analysis (steamed buns, dumpling skins) 100 mesh, 120 mesh, 140 mesh 120 mesh≥85% Medium fineness, commonly used standard test sieves

Whole wheat flour impurity screening and particle size classification 60 mesh, 80 mesh, 100 mesh 80 mesh≥70% contains more bran, use a coarse screen to remove large particles in the initial screening

Special refined flour quality classification (high-end pastries) 140 mesh, 160 mesh, 180 mesh 160 mesh≥97% requires extremely high fineness, requires a combination of multiple screens

First-class flour quality classification (ordinary pasta) 80 mesh, 100 mesh, 120 mesh 100 mesh≥85% suitable for large-scale production, screening efficiency is prioritized

Second-class flour quality classification (low-end pasta) 60 mesh, 80 mesh, 100 mesh 80 mesh≥70% lower fineness requirements, just remove large particles of impurities in the initial screening

General flour impurity screening (food safety) 60 mesh, 80 mesh, 150 mesh 150 mesh impurities≤0.05% 60 mesh is used for initial screening of bran and sand, 150 mesh is used for fine screening of tiny foreign matter

Operational precautions:

Sample volume: 100-200g, multiple sampling to ensure representativeness.

Environment: Dust-free, constant temperature and humidity (20-25°C, 50-60% humidity).

Screen cleaning: Use a soft brush or ultrasonic cleaning after screening to avoid cross contamination.

1. Raw material acceptance link of flour mills-testing wheat grinding suitability

In the upstream of the flour mill production process, the test sieve is used to test the physical properties of incoming wheat, especially the particle distribution analysis after the crushing test. The general operation process is: sampling from wheat from different origins or batches; preliminary grinding of samples; using standard analysis sieves (such as 200mm test sieves) for particle size screening; calculating the ratio of coarse and fine particles, evaluating its grinding suitability and predicted value of flour yield.

2. Quality monitoring of flour making process - particle size analysis of products in each grinding section

In the flour making workshop, flour production is carried out through multiple grinding and screening systems, and each grinding section (such as one skin, one heart, two skins, two hearts, etc.) produces powder of different particle sizes. The test sieve for flour quality control is used to: sample powder from each grinding section; use multi-layer screens for classification; analyze the residue of each screen layer to determine the particle size composition of powder in each section.

3. Product stability analysis - batch comparison test

In the quality management system of flour enterprises, maintaining batch product stability is a long-term goal. The test sieve for flour quality control can be used to screen and compare flour samples produced on different production dates, in different workshops, and even in different teams: use a unified sieve and screening time conditions; record the difference in pass rate and sieve residue; analyze the causes of fluctuations, such as raw material changes, equipment aging, inconsistent operations, etc.

4. Research and product development link - new product fineness research

When developing new varieties such as high-gluten flour, dumpling flour, and special baking powder, the test sieve for flour quality control is used to explore the relationship between particle size and water absorption, dough extensibility, and fluffiness. For example: sieve samples of different fineness levels for performance comparison; adjust the process to find the best powder structure; use with a flour quality meter to form a complete flour quality evaluation system to support accurate flour mixing and personalized product development.

By analyzing the particle composition of flour through the test sieve for flour quality control , it is possible to effectively evaluate whether the grinding fineness of the flour meets the standard and determine whether there are problems such as excessive bran residue or too fine flour. These characteristics directly affect the quality control of flour, including its water absorption, rheology, and the taste and appearance of the final product. Therefore, the test sieve is a key step in ensuring the stability of flour quality.

What is the wet sieving process?

Wet sieving process is a sieving process assisted by a liquid (usually water or a solution containing a dispersant) to more effectively...

Fines content tester can be defined as an instrument used to quantitatively determine the content of fines powder components of a specific fineness...

Micro silica powder particle size analysis test sieve

Micro silica powder, also known as silica fume, is an ultrafine active silica material with a very small particle size, usually between 0.1-0.3 microns, which...

Agricultural gruesos Test sieves

Agricultural gruesos test sieves are experimental equipment used for particle size analysis, grading and testing of agricultural soil, gruesos...

Stainless steel frame and woven cloth

The test sieve is a laboratory equipment used for particle size analysis. Its core components usually include a stainless steel frame and woven cloth (also called a sieve)...

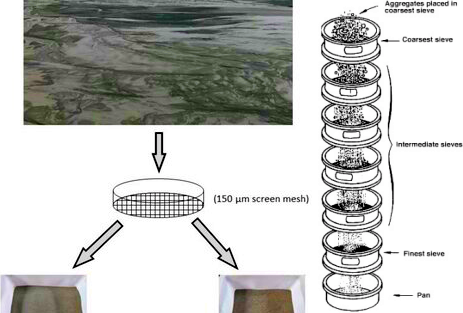

test sieve for aggregate particle size

The test sieve for aggregate particle size is a set of wire mesh sieves that meet specific standards, designed to separate aggregate samples into different particle size...

May 15, 2025

Test sieve for flour quality control

The test sieve is an indispensable key screening equipment in flour quality control. It can grade and...

May 14, 2025

test sieve for aggregate particle size

The test sieve for aggregate particle size is a standard sieve used to evaluate the particle size dis...

May 13, 2025

Test sieve for pharmaceutical powder

Test sieve for pharmaceutical powder is a special equipment used in the pharmaceutical industry for a...

May 12, 2025

Test sieve for cement fineness

Test sieve for cement fineness is a key tool for evaluating cement particle size distribution and gri...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap