Tuesday May-13 2025 16:46:00

Test sieve for pharmaceutical powder is a special equipment used in the pharmaceutical industry for screening and detecting the particle size of pharmaceutical powder. Its main function is to separate pharmaceutical powder particles through sieves of different meshes and control the particle size distribution. It is composed of a series of standard sieves of different meshes stacked together, and each sieve has a precise mesh size.

The commonly used sieve mesh range is 20-200 mesh, depending on the use of the pharmaceutical powder. For example, tablet preparation often uses 80-120 mesh sieves. The test sieve can effectively remove oversized or undersized particles, ensure the uniformity and stability of pharmaceutical powder, and is widely used in the quality control of raw materials, Chinese medicine powder, etc.

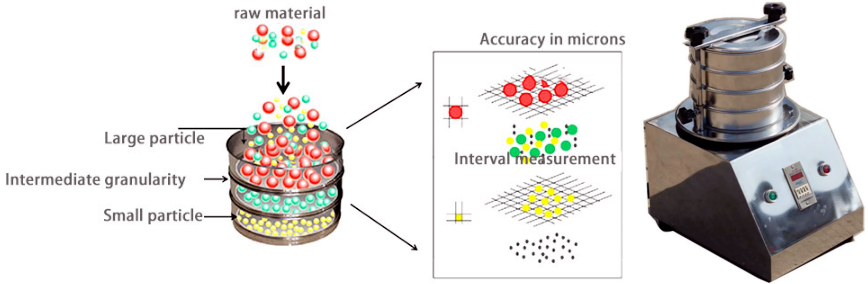

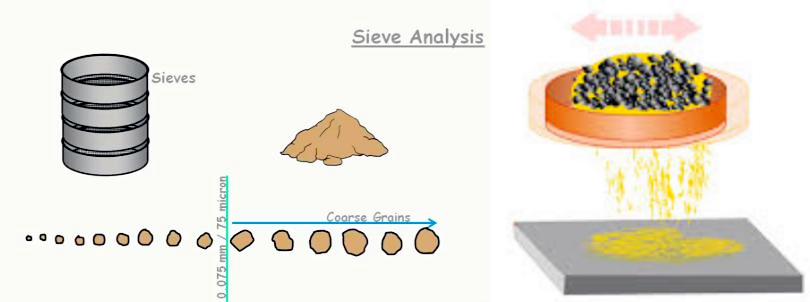

① The working principle of test sieve for pharmaceutical powder is based on mechanical sieving, and the core process is to use a series of standard sieves with gradually decreasing apertures.

② Through mechanical vibration or shaking, the pharmaceutical powder sample is moved on the sieve and separated according to the size of the particles.

③ When the pharmaceutical powder is placed on the top layer of the sieve with the largest aperture, fine particles smaller than the mesh size will pass through the sieve and fall to the next layer of sieve under the action of gravity and vibration. Coarse particles larger than the mesh size will be retained on this layer of sieve. As the vibration continues, the pharmaceutical powder will gradually pass through each layer of sieve. Each layer of sieve only allows particles smaller than its mesh size to pass through

④ In the end, pharmaceutical powders of different particle size ranges will be retained on sieves of different mesh sizes or collected in the collection tray at the bottom.

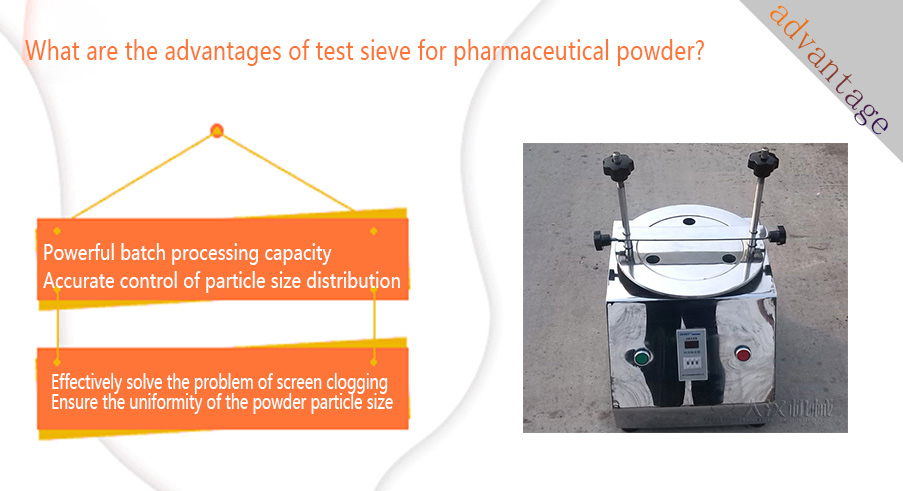

Powerful batch processing capacity: Pharmaceutical production covers all stages from small-scale R&D trials to large-scale commercial production. Traditional screening equipment often has a single specification and is difficult to meet the needs of different production capacities. The advantage of test sieve for pharmaceutical powder lies in its diversity of machine specifications, such as from a small test machine with a diameter of 400mm to a large production line equipment with a diameter of 1500mm.

Accurate control of particle size distribution: The key characteristics of pharmaceuticals such as efficacy, absorption rate, and solubility are often closely related to the particle size distribution of pharmaceutical powder. The pharmaceutical powder test sieve usually uses a high-tension, high-precision metal woven screen with a mesh range of 80-500 mesh or even higher, which can fully disperse the pharmaceutical powder particles on the sieve surface and efficiently pass through the corresponding mesh according to their particle size, thereby achieving precise control of the pharmaceutical powder particle size distribution.

Effectively solve the problem of screen clogging: small or sticky pharmaceutical powders are easy to clog the sieve holes. Test sieve for pharmaceutical powder uses high-frequency vibration (vibration frequency can reach about 3000 times/minute) or ultrasonic screen cleaning device to vibrate the screen or use sound waves to detach particles and keep the sieve holes unobstructed. The mesh size of the sieve (for example, 20-200 mesh, corresponding to the aperture range of 0.075-0.85mm) accurately matches the characteristics of the powder to avoid clogging of the fine sieve holes.

Ensure the uniformity of the powder particle size: The uneven particle size distribution of the powder will directly affect the uniformity, dissolution rate and bioavailability of the pharmaceutical. The powder test sieve usually supports the design of multiple layers of sieves (2-5 layers or even more). The mesh size (aperture) of each layer of sieve is different, gradually decreasing from top to bottom. Through the step-by-step filtration of multiple layers of sieves, the powder can be effectively separated into components with different particle size ranges to achieve graded screening.

|

Medicinal powder type |

Sieving purpose |

Recommended mesh range (mesh) |

Corresponding particle size (μm) |

|

Raw material powder |

Fine screening, grading |

120~300 mesh |

125~48μm |

|

Traditional Chinese medicine fine powder |

Remove coarse particles |

60~120 mesh |

250~125μm |

|

Traditional Chinese medicine ultrafine powder |

Particle size control |

200~400 mesh |

74~38μm |

|

Pharmaceutical excipients (lactose, starch) |

removal of impurities, control of particle size |

80~200 mesh |

180~74μm |

|

Granular powder |

grading, whole grain |

20~80 mesh |

850~180μm |

|

Powder for granules |

uniform particle size |

40~100 mesh |

425~150μm |

|

Pre-tablet powder for western medicine |

removal of impurities, control of particle size |

100~200 mesh |

150~74μm |

|

Sterile powder (freeze-dried powder, etc.) |

removal of lumps or foreign matter |

200~400 mesh |

74~38μm |

When the powder enters the feed port, the sieve body starts to vibrate in three dimensions, and the material diffuses outward on the sieve. According to the different mesh numbers of the sieve, the powder is sieved by the test sieve for pharmaceutical powder into two parts: the passing net and the retention net; qualified fine powder is discharged from the lower discharge port, and coarse impurities or foreign matter are discharged from the upper discharge port to achieve detection and screening.

1. Particle size control of APIs

Controlling the average particle size: ensuring that the average particle size of the API meets the process requirements directly affects the dissolution rate, absorption rate and bioavailability of the pharmaceutical. For example, some oral solid preparations require APIs of a specific fineness to ensure rapid release.

Removing oversized particles: avoiding oversized particles in the API, which may cause uneven mixing, difficulty in tableting or affect the appearance and stability of the final product.

2. Quality control during the production of pharmaceutical preparations

Mixed uniformity detection: after the pharmaceutical preparations of multiple ingredients are mixed, the distribution of particles of different components can be checked by the powder test sieve to ensure the accuracy of the dosage.

Particle size optimization before tableting or capsule filling: appropriate particle size distribution helps the fluidity and compressibility of the powder, improves the hardness and appearance quality of the tablets, or ensures the uniformity of capsule filling.

Particle size classification of granules or dry suspensions: when producing granules or dry suspensions, using powder test sieves of different specifications can obtain products with the required particle size range to ensure their dispersibility and solubility.

Check foreign matter in the production process: The test sieve for pharmaceutical powder can effectively remove foreign matter such as metal chips and fibers that may be mixed in during the production process to ensure the safety of the pharmaceutical.

3. Quality inspection of finished pharmaceuticals

Check the disintegration or dissolution of tablets or capsules: Although the test sieve for pharmaceutical powder is not directly used for disintegration or dissolution testing, the particle size of APIs and intermediates will significantly affect these indicators. Therefore, when inspecting finished products, the particle size distribution of APIs or key intermediates is sometimes traced back.

Evaluate the uniformity of powders or granules: For finished powders or granules, the test sieve for pharmaceutical powder can be used to check whether its particle size distribution meets the standard and judge the uniformity of product quality.

Test sieve for pharmaceutical powder plays an important role in all aspects of the pharmaceutical industry and is one of the key equipment to ensure the quality, safety and efficacy of pharmaceuticals. Its application scenarios are wide and run through the entire life cycle from APIs to finished pharmaceuticals.

What is the wet sieving process?

Wet sieving process is a sieving process assisted by a liquid (usually water or a solution containing a dispersant) to more effectively...

Fines content tester can be defined as an instrument used to quantitatively determine the content of fines powder components of a specific fineness...

Micro silica powder particle size analysis test sieve

Micro silica powder, also known as silica fume, is an ultrafine active silica material with a very small particle size, usually between 0.1-0.3 microns, which...

Agricultural gruesos Test sieves

Agricultural gruesos test sieves are experimental equipment used for particle size analysis, grading and testing of agricultural soil, gruesos...

Stainless steel frame and woven cloth

The test sieve is a laboratory equipment used for particle size analysis. Its core components usually include a stainless steel frame and woven cloth (also called a sieve)...

Test sieve for cement fineness

Test sieve for cement fineness is often called cement fineness sieve or cement sieving sieve. It is a key experimental instrument for cement fineness testing.

May 13, 2025

Test sieve for pharmaceutical powder

Test sieve for pharmaceutical powder is a special equipment used in the pharmaceutical industry for a...

May 12, 2025

Test sieve for cement fineness

Test sieve for cement fineness is a key tool for evaluating cement particle size distribution and gri...

May 10, 2025

The test sieve for sand grading is a device that uses mechanical vibration and multi-layer standard s...

May 09, 2025

Test sieve for soil analysis is a key tool for soil particle size distribution analysis. It grades so...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap