Friday May-09 2025 16:40:52

Test sieve for soil analysis is an important tool for soil particle size distribution analysis. Its main function is to grade and sieve soil samples according to particle diameter. It is usually composed of multiple sieves with a standard diameter of 200mm or 300mm. The sieve aperture covers the range of 0.075mm (200 mesh) to 4.75mm (4 mesh). Commonly used sieve meshes include: 20 mesh, 40 mesh, 60 mesh, 80 mesh, etc. The larger the mesh number, the smaller the sieve aperture, and the finer particles can be screened out. In soil analysis, the sample is graded through a series of sieves with different mesh numbers, and the mass percentage of each particle level is finally obtained. These data are of great significance for soil classification, engineering construction, agricultural management and environmental monitoring.

Grading analysis: Separate particles of different particle sizes in the soil (such as 0.074mm to 60mm) by screening particle method to determine the particle size distribution of the soil. It is suitable for soil analysis with a particle size greater than 0.074mm.

Soil composition detection: Used for the determination of chemical properties such as soil nitrogen, potassium, carbonate, etc., to screen out soil of different fineness for subsequent experiments.

Particle classification and filtration: Soil particles are classified in the laboratory to separate particles of different sizes and speed up the experimental process.

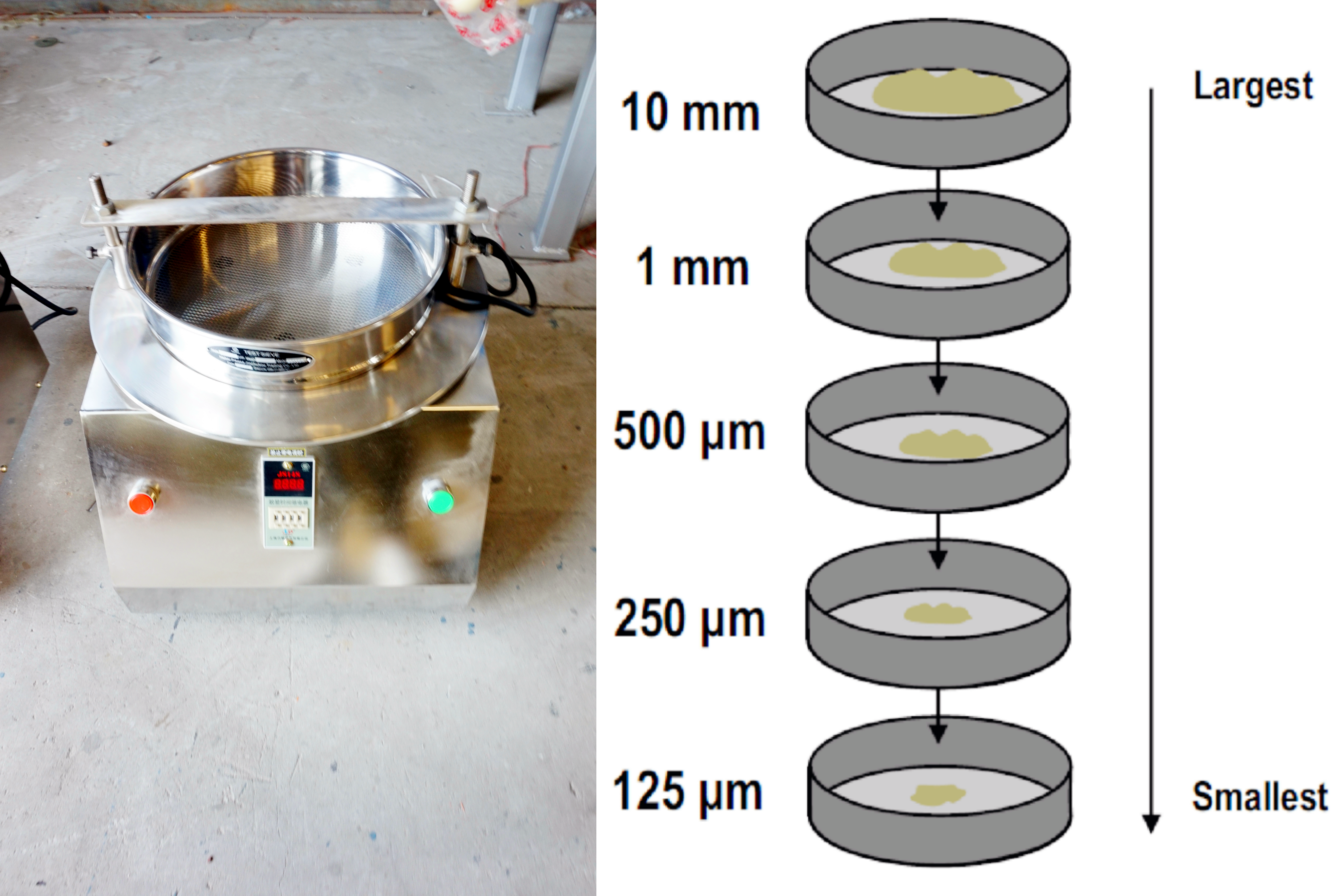

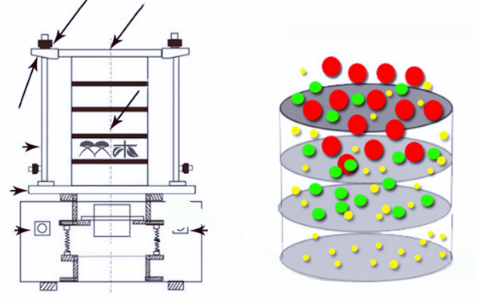

① The test sieve for soil analysis is usually a series of sieves with different mesh sizes, which are stacked in order from large to small mesh sizes.

② Place the dry soil sample on the top sieve, and then use the vibration motor to generate horizontal, vertical and inclined three-dimensional vibrations through mechanical vibration, and then transmit this vibration to the standard analysis sieve and material surface, so that the soil particles continue to jump, roll and move on the sieve surface.

Particles smaller than the sieve holes fall through the sieve holes to the next sieve or collection container, while particles larger than the sieve holes remain on the sieve surface, thereby achieving the classification of soil particles according to particle size

③ Finally, weigh the mass of soil remaining on each sieve and calculate the percentage of each particle size range to obtain the particle size distribution of the soil.

Soil does encounter many challenges during the screening process, and the design and use of test sieves for soil analysis is to overcome these problems as much as possible and ensure the accuracy and reliability of the analysis results.

Adjust the soil pretreatment method: If the soil moisture content is high, the soil can be air-dried or dried first to reduce its moisture content and reduce sticky pores. For soils with high viscosity, dispersants can also be added to change the interaction between soil particles so that they are not easy to stick together. The test sieve for soil analysis pre-treats the soil by crushing and grinding before screening to break up larger soil blocks, which can prevent large particles of soil from clogging the screen.

Control the feed amount and feed speed: Avoid excessive or too fast feeding to cause soil to accumulate on the screen, and ensure that the soil can enter the test sieve evenly and slowly so that the screen can fully play its role. Choose a suitable test sieve and ensure that its strength and amplitude are moderate so that the soil particles can fully jump and slide on the screen to overcome the adhesion between particles and allow the material to pass through the screen quickly. Control the vibration time to avoid being too long or too short to achieve a better screening effect.

Reduce the problem of soil sample loss: Some test sieves are designed with a relatively closed screening space, such as a screening box with a sealed cover or enclosure, which can prevent soil samples from spilling during the screening process. Reasonable design of the discharge port and the receiving device ensures that the sieved soil can be collected smoothly and reduces the omission of samples. When screening soil, operators should follow the standard operating procedures. For example, when pouring soil samples into the test sieve, the action should be gentle to avoid sample splashing.

Solve the problem of irregular soil particle shape: Some soil particles are irregular in shape and may be stuck in the sieve holes smaller than their theoretical size in the long axis direction. The test sieve for soil analysis can extend the screening time to ensure that particles in different directions have the opportunity to pass through the appropriate sieve holes. Appropriately adjust the vibration intensity to avoid particle breakage caused by severe vibration.

|

Particle size range (mm) |

Corresponding mesh size |

Sieve aperture (μm) |

Application scenario |

|

2.0-0.85 |

10 mesh |

2000 |

Coarse sand separation (such as construction sand) |

|

0.85-0.425 |

20 mesh |

850 |

Medium sand separation |

|

0.425-0.15 |

40 mesh |

425 |

Fine sand separation |

|

0.15-0.075 |

100 mesh |

150 |

Preliminary screening of very fine sand/silt |

|

<0.075 |

200 mesh |

75 |

Clay analysis (wet sieving method required) |

Guide to planting and soil improvement: To understand the texture of the soil (such as sandy loam, loam, clay loam), sieve it through a set of standard test sieves (for example, sieves with apertures of 2mm, 0.25mm, 0.05mm, etc.). The screening results of the test sieve for soil analysis can clearly show the proportion of sand, silt and clay. For example, if the sand content is too high, the soil may have poor water and fertilizer retention capacity; if the clay content is too high, the soil may be compacted and have poor air permeability.

Evaluate foundation stability and select building materials: When conducting foundation surveys for bridges, buildings, etc., it is necessary to evaluate the engineering properties of the soil. Particle grading (obtained through sieving analysis) is one of the important indicators. The particle composition of the soil directly affects its engineering properties such as compaction, permeability, and shear strength. For example, well-graded gravel soil has high bearing capacity and stability. Test sieves for soil analysis can also be used to screen building materials such as sand and gravel to ensure that their particle size distribution meets the requirements.

Explore the soil formation process and physical properties: When conducting basic research in the laboratory, test sieves are used to separate soil components of different particle sizes to study their mineral composition, organic matter content, specific surface area and other properties. Soil particles of different particle sizes play different roles in soil formation, nutrient circulation and water retention. By controlling the variable of soil particle size, we can have a deeper understanding of the physical and chemical processes of soil and provide experimental basis for establishing a more complete soil theory.

Tracking pollutant migration and assessing soil health: In environmental pollution investigations, it is necessary to analyze the distribution of pollutants in the soil. Test sieves for soil analysis can be used to separate soil components of different particle sizes, and then analyze the pollutant concentration of these components separately. Soil particles of different particle sizes have different adsorption capacities for pollutants. For example, fine particles (clay particles and silt particles) usually have a larger specific surface area than coarse particles and are more likely to adsorb heavy metals and organic pollutants.

In short, the application of test sieve for soil analysis is very wide, involving almost all fields that need to understand the physical properties of soil. Through simple and effective screening methods, key soil particle composition information can be obtained, providing important basic data and decision-making basis for agricultural production, environmental protection, engineering construction and scientific research.

What is the wet sieving process?

Wet sieving process is a sieving process assisted by a liquid (usually water or a solution containing a dispersant) to more effectively...

Fines content tester can be defined as an instrument used to quantitatively determine the content of fines powder components of a specific fineness...

Micro silica powder particle size analysis test sieve

Micro silica powder, also known as silica fume, is an ultrafine active silica material with a very small particle size, usually between 0.1-0.3 microns, which...

Agricultural gruesos Test sieves

Agricultural gruesos test sieves are experimental equipment used for particle size analysis, grading and testing of agricultural soil, gruesos...

Stainless steel frame and woven cloth

The test sieve is a laboratory equipment used for particle size analysis. Its core components usually include a stainless steel frame and woven cloth (also called a sieve)...

Herbal Powder Lab Sieve Shaker

Herbal powder lab sieve shaker is an experimental instrument designed for the particle size classification of Chinese herbal medicine powder.

May 09, 2025

Test sieve for soil analysis is a key tool for soil particle size distribution analysis. It grades so...

May 08, 2025

Herbal Powder Lab Sieve Shaker

The herbal powder lab sieve shaker is a laboratory equipment specially used for screening, impurity r...

May 07, 2025

Stainless Steel Grain Granule Test Sieve for Lab

Stainless steel grain granule test sieve for lab is a key analytical tool. Through different mesh siz...

May 06, 2025

Test sieve shaker for seed analysis

The test sieve shaker for seed analysis is an important seed analysis equipment, widely used in agric...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap