Tuesday November-04 2025 17:44:24

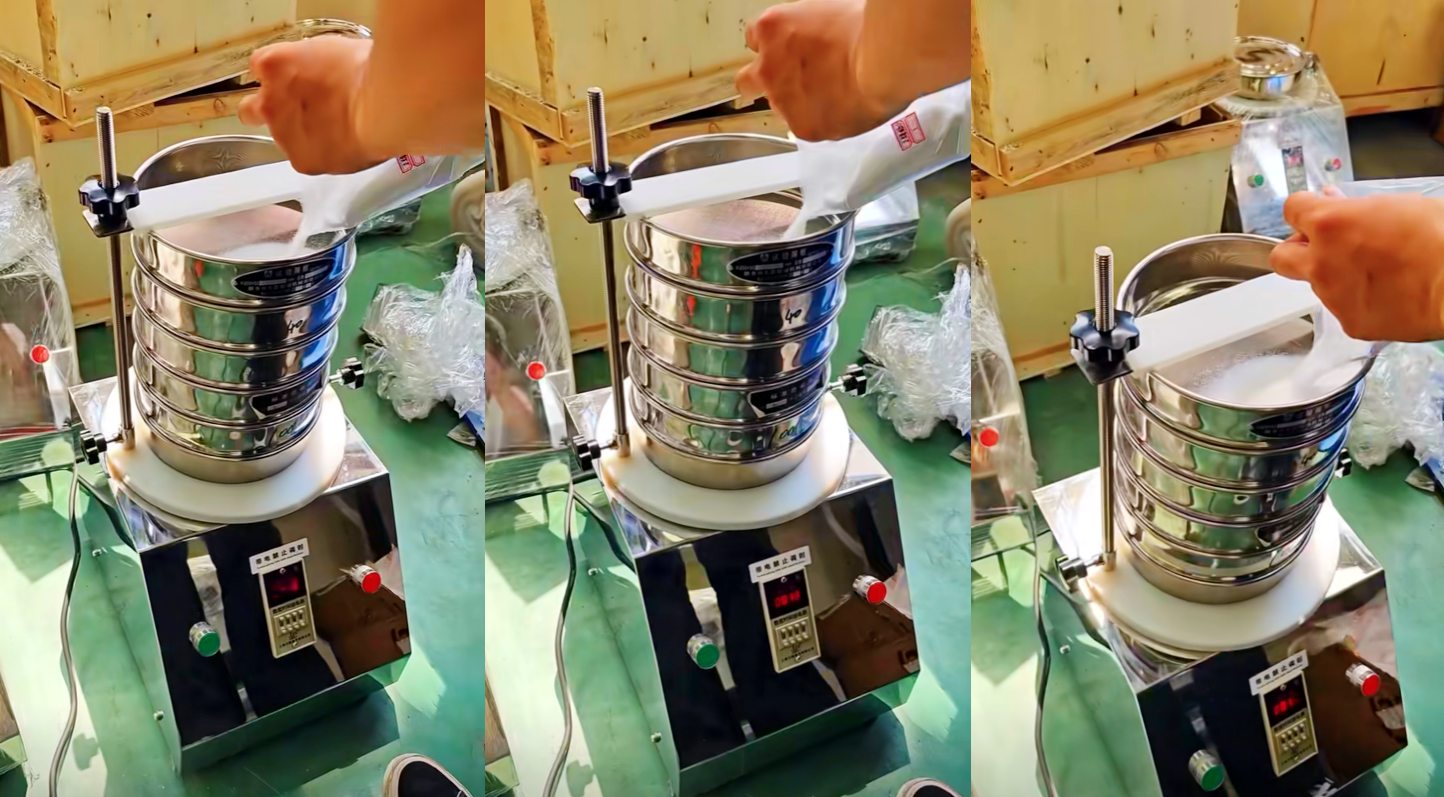

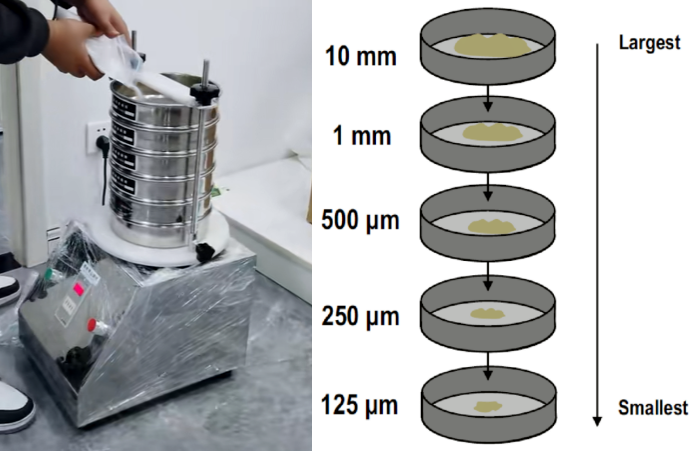

Test sieve sugar powder size detection is a key method for evaluating the fineness of sugar powder and its particle distribution. It uses one or more sets of standard test sieves with precise apertures to mechanically vibrate and screen sugar powder samples. This method uses the vertical and horizontal composite vibrations provided by the test sieve equipment to achieve efficient separation of sugar powder on sieves with different apertures.

The sieves are usually arranged from top to bottom according to the aperture size, such as 850μm, 500μm, 250μm, etc. Through screening, the proportion of each particle size segment in sugar powder can be clearly reflected, and its fineness and uniformity can be accurately judged.

Test sieve sugar powder size detection is of great significance in food processing and quality control. As an important raw material widely used in baking, candy and beverage industries, the particle size of powdered sugar directly affects the key quality characteristics of the product, such as taste, dissolution rate, fluidity and mixing uniformity. Particle size detection through test sieves can accurately evaluate the particle distribution of powdered sugar.

For example, too coarse particles may cause a rough taste, while too fine powder may cause agglomeration or poor fluidity. In addition, the layered structure of the test sieve can effectively distinguish powdered sugar with different particle size ranges, helping to achieve refined quality management.

In the particle size detection analysis of powdered sugar, the effective size (EffectiveParticleSize) is one of the important parameters for evaluating the particle size distribution characteristics. It usually represents the most representative particle size in the sample and can be used to control quality or design production processes. Commonly used "effective sizes" usually include:

D10 (10% particle size): indicates that 10% of the mass of particles in the particle group is smaller than this size

D50 (median diameter/median particle size): indicates that 50% of the particles are smaller than this particle size, often used as the effective particle size

D90: indicates that 90% of the particles are smaller than this particle size

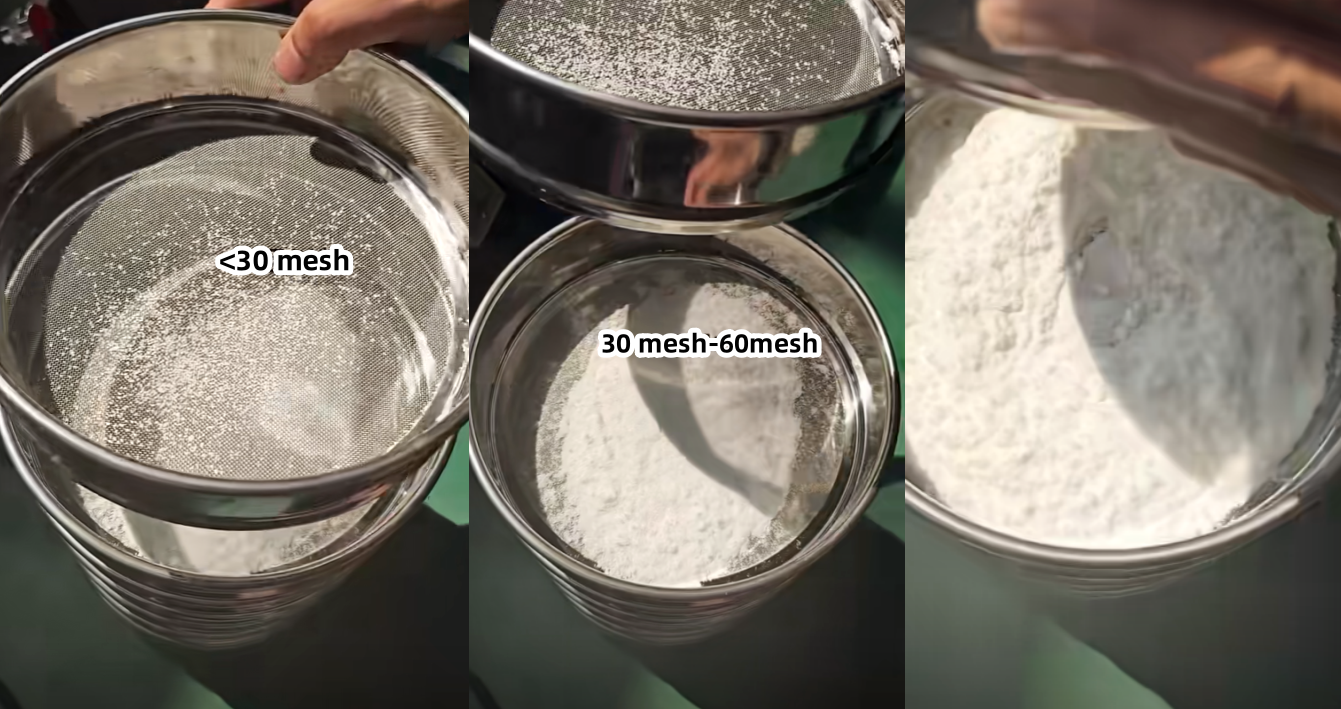

Due to different uses (such as baking, pharmaceuticals, beverages, etc.), the particle size requirements of sugar powder vary greatly. When using the test sieve for sugar powder particle size detection, choosing the appropriate mesh number is the key to ensuring accurate analysis.

|

Mesh number (mesh) |

Corresponding pore size (μm) |

Applicable instructions |

Mesh number (mesh) |

Corresponding pore size (μm) |

Applicable instructions |

|

20 mesh |

~850μm |

Particle size coarse sugar, preliminary classification |

30 mesh |

~600μm |

Granular sugar or coarse sugar powder detection |

|

40 mesh |

~425μm |

Common coarse sugar powder |

50 mesh |

~300μm |

Conventional fine sugar powder classification |

|

80 mesh |

~180μm |

Common particle size of food-grade sugar powder |

10 0 mesh |

~150μm |

Frosting or powdered sugar (medium fine) |

|

120 mesh |

~125μm |

Fine powdered sugar |

150 mesh |

~106μm |

High-grade powdered sugar |

|

200 mesh |

~75μm |

Extra fine powdered sugar, fast-dissolving powdered sugar |

325 mesh |

~45μm |

Ultra fine powdered sugar, pharmaceutical grade powdered sugar detection |

The test sieve powdered sugar particle size detection plays an important role in the powdered sugar screening scenario. In the food processing scenario, baking companies test the powdered sugar particle size to ensure that it meets the needs of different products. For example, when making cakes, fine powdered sugar (100-150 mesh) can dissolve quickly to make the cake delicate; making decorative frosting requires finer powdered sugar (about 200 mesh) to ensure smooth application. In beverage production, precise control of powdered sugar particle size can avoid problems such as slow dissolution and precipitation due to excessively large particles.

In pharmaceutical production, powdered sugar is often used as a coating powder or excipient, which requires higher uniformity of particle size. The test sieve can effectively control the median particle size (such as D50) within the standard range. During the production process, the test sieve can also be used to inspect the raw material powdered sugar, sieve out coarse particles or agglomerates, and ensure the stability of the subsequent process. In addition, during research and development or debugging of new formulas, particle size detection can also be used to optimize the powder mixing ratio and improve product performance.

In summary, the test sieve powdered sugar particle size detection is not only to understand the particle size, but also a key link to ensure product functionality, quality stability, processing efficiency and food safety. It is a necessary means for manufacturers to conduct quality management, process optimization and meet consumer expectations.

What is the wet sieving process?

Wet sieving process is a sieving process assisted by a liquid (usually water or a solution containing a dispersant) to more effectively...

Fines content tester can be defined as an instrument used to quantitatively determine the content of fines powder components of a specific fineness...

Micro silica powder particle size analysis test sieve

Micro silica powder, also known as silica fume, is an ultrafine active silica material with a very small particle size, usually between 0.1-0.3 microns, which...

Agricultural gruesos Test sieves

Agricultural gruesos test sieves are experimental equipment used for particle size analysis, grading and testing of agricultural soil, gruesos...

Stainless steel frame and woven cloth

The test sieve is a laboratory equipment used for particle size analysis. Its core components usually include a stainless steel frame and woven cloth (also called a sieve)...

Chemical Material Standard Laboratory Vibrating Sifter

Chemical material standard laboratory vibrating sifter is a screening equipment dedicated to experimental analysis and particle size detection of chemical raw...

Nov 04, 2025

Test sieve sugar powder size detection

Test sieve sugar powder size detection is a physical detection method that uses multiple layers of st...

Nov 01, 2025

Test sieves for reliable sieve analysis

Test sieves for reliable sieve analysis use high-precision stainless steel test sieves with mesh conf...

Oct 30, 2025

Laboratory woven wire mesh sieves

Laboratory woven wire mesh sieves are screening tools made of 250 mm stainless steel frame and precis...

Oct 30, 2025

Sieve Mesh is a metal or non-metal device used to separate materials. Its mesh count refers to the nu...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap