Monday July-07 2025 17:48:40

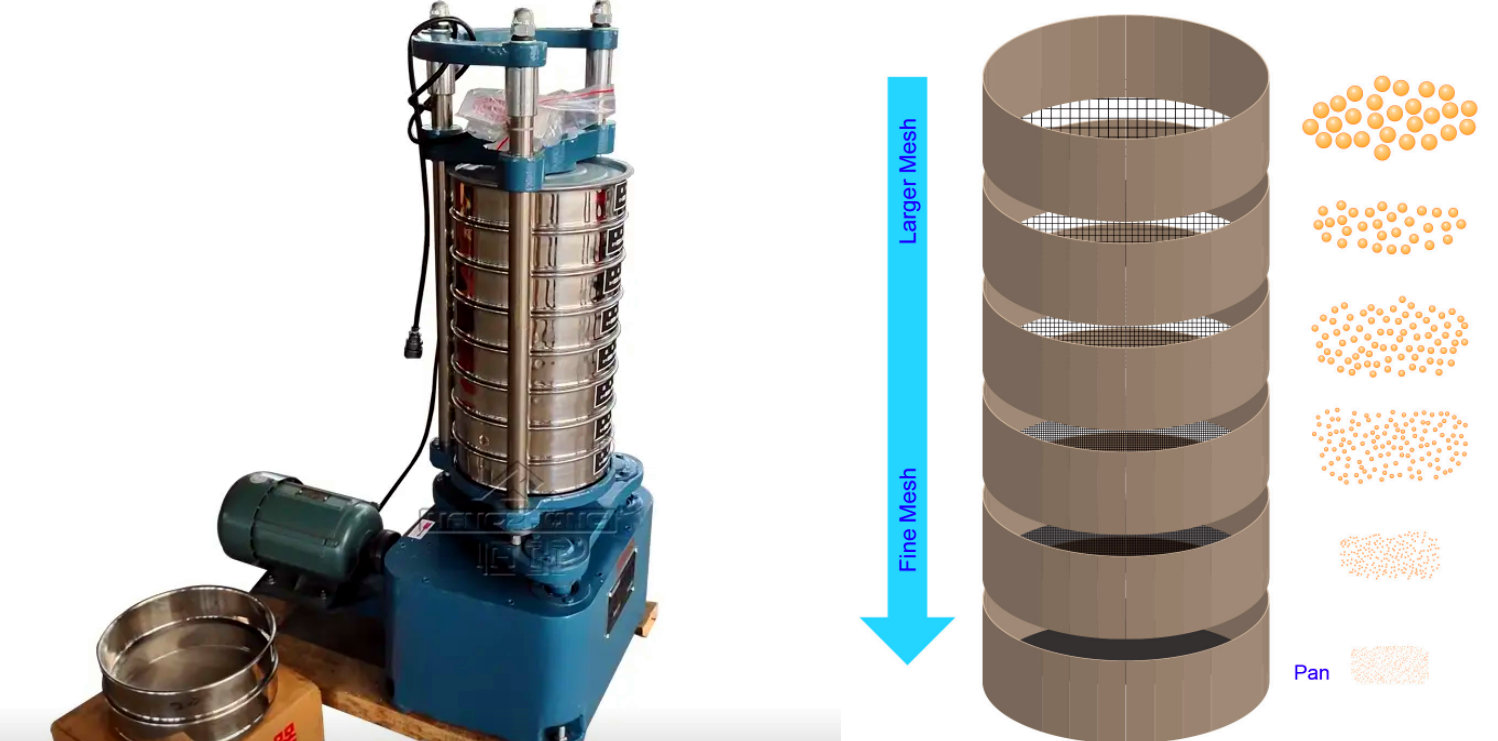

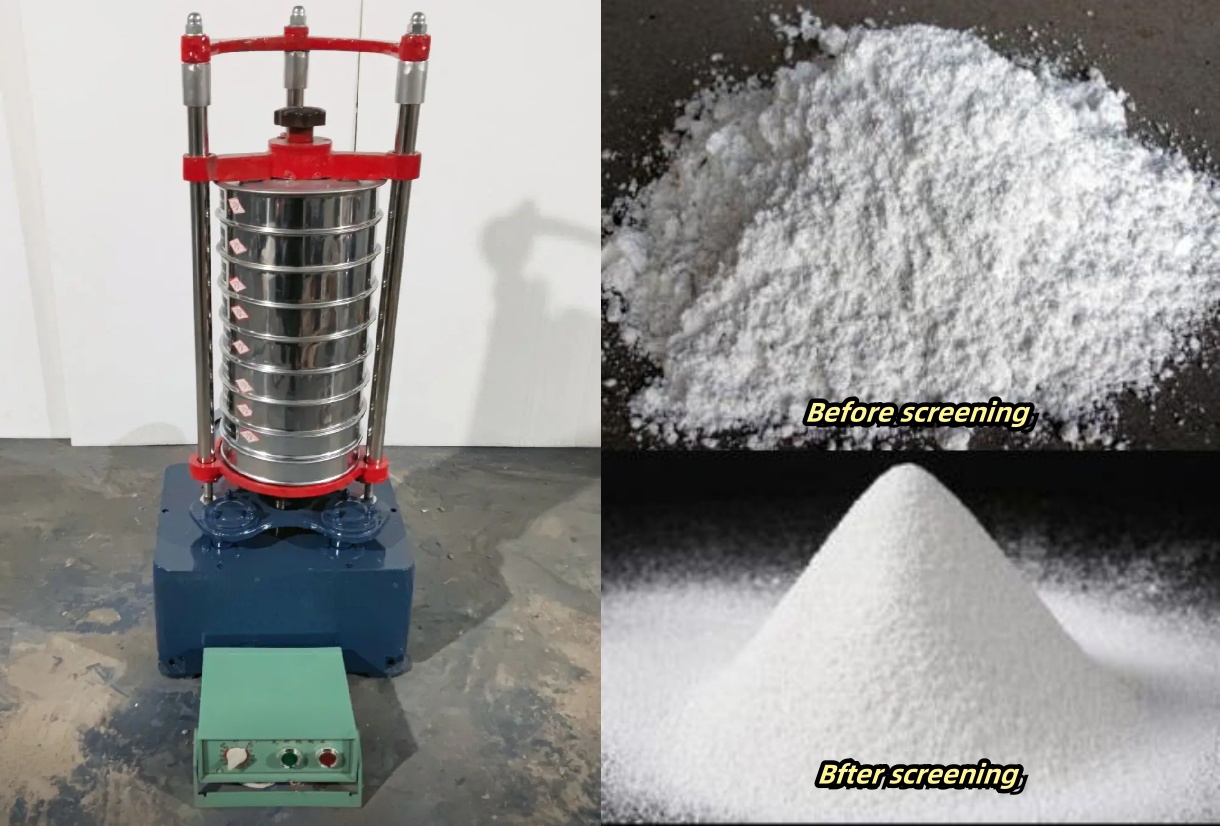

Top impact sieve for particle size inspection is mainly used for fine screening and particle size distribution determination of powder materials. Its core function is to grade the sample layer by layer in the standard test sieve through top mechanical impact and lateral slap vibration, and quickly separate particles of different particle sizes. This design is particularly suitable for materials that are difficult to screen effectively through pure vibration, such as some powders that are easy to agglomerate, adhere to the sieve, or require stronger mechanical action to pass through the sieve holes.

Top impact sieve for particle size inspection with a multi-layer standard test sieve. Each layer of the screen has a different aperture, which decreases from top to bottom to form a particle size distribution structure. According to the test standard, the corresponding number of screen layers and mesh configurations are selected, for example, from 20 mesh to 800 mesh, to detect the particle size composition of the material.

|

Model |

Screen diameter |

Number of layers |

Main features |

Scope of application |

|

TJ-200 top impact screen |

200mm |

1-8 layers |

Small and compact, suitable for small batch sample testing |

Chemical powder, food particles, small samples |

|

TJ-300 top impact screen |

300mm |

1-8 layers |

Classic general model, suitable for most laboratory testing needs |

Mineral powder, building materials, pharmaceutical powder |

|

TJ-450 top impact screen |

450mm |

1-8 layers |

Large screen surface, suitable for larger samples Quality inspection, high efficiency |

cement, metallurgy, industrial powder |

|

TJ-500 top impact screen |

500mm |

1-8 layers |

large screening area, suitable for large samples and long-term screening |

building materials, mining, heavy industry powder |

|

TJ-600 top impact screen |

600mm |

1-8 layers |

high efficiency and durability, adapted to industrial site quality control requirements |

cement, ore powder, chemical products |

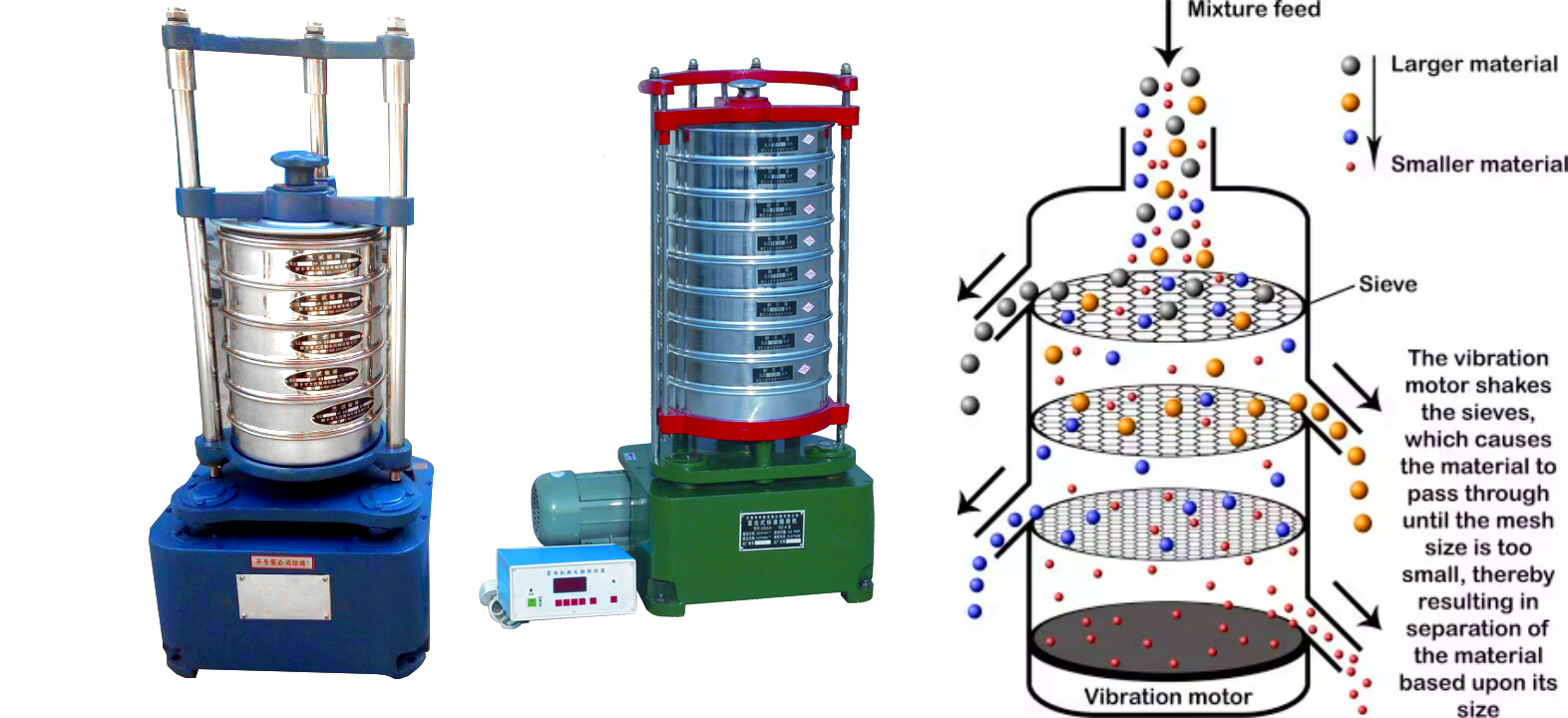

The working principle of the top impact sieve for particle size inspection is to achieve fast and effective particle classification of materials on multi-layer standard sieves through a combination of vertical tapping and horizontal rotation, thereby completing particle size analysis. Its core purpose is to simulate the "beating + rotating" action in manual screening to improve screening efficiency and accuracy.

Vertical tapping: The top impact sieve for particle size inspection is equipped with an eccentric mechanism or cam mechanism, which is driven by a motor to continuously knock or tap the screen group in a vertical direction. This impact force can loosen the material, help the particles penetrate the screen holes, and prevent the screen surface from being blocked.

Horizontal rotation: While the screen frame is vertically tapped, it slowly rotates horizontally to evenly spread the material on the screen, avoid concentrated accumulation, and improve screening uniformity and efficiency.

This composite movement enables the top-impact screen to quickly and accurately complete the screening of multiple layers of screens, which is particularly suitable for particle size analysis and inspection of dry powder, granules and other materials.

Provide vibration and impact force: The top impact sieve for particle size inspection drives the mechanism to vibrate up and down through the motor, so that the particles on the screen are thrown up so that the particles have more opportunities to pass through the sieve holes. Tapping/impact: This is the core feature of the top impact sieve. It periodically taps the screen assembly to generate additional impact force. This impact force can effectively:

Break the agglomeration of particles: For some materials that are easy to stick or agglomerate, the knocking force can help separate the particles and make them easier to pass through the sieve holes.

Clean the sieve holes: knocking helps to remove particles blocked in the sieve holes and prevent the sieve holes from being blocked, thereby ensuring the continuity and accuracy of screening.

Promote the passage of particles: the impact force can give the particles a downward component, so that they can pass through the sieve holes of suitable size faster, especially for particles close to the size of the sieve holes.

Achieve three-dimensional movement: The top impact sieve for particle size inspection usually also has a rotation function, so that the particles on the screen not only vibrate up and down, but also rotate on the screen surface. This three-dimensional movement combined with vibration and rotation ensures that each particle has enough opportunities to contact the sieve holes and pass through the sieve holes in the correct direction, thereby improving the efficiency and accuracy of screening.

The top impact sieve for particle size inspection, also known as the tapping screen, is a commonly used screening equipment in particle size inspection. It simulates the process of manual screening through unique tapping and rotation movements, allowing the particles to move three-dimensionally on the screen, thereby achieving efficient and accurate screening effects. It is widely used in various industries that require particle size analysis, especially for the following types of materials:

Powdered materials: such as cement, flour, pharmaceutical powder, pigment, abrasive, etc.

Granular materials: such as sand, grain, fertilizer, metal powder, etc.

Materials that are difficult to disperse or easily agglomerated: The tapping movement of the top impact sieve for particle size inspection helps to break the agglomeration between particles and improve screening efficiency.

Cement particle size analysis:During the cement production process, the product must test its fineness index. Use the top impact sieve for particle size inspection with a 75μm (200 mesh) test sieve to screen the cement powder sample and test whether the retention rate is within the standard allowable range (generally not more than 10%) to determine whether it meets the construction requirements.

Chinese herbal medicine powder inspection:In the production of Chinese herbal powder, fine powder must meet the specified particle size requirements before it can be packaged and sold. Use the top impact sieve for particle size inspection for routine batch particle size testing to ensure that the powder screening rate of different medicinal materials is consistent and avoid dosage errors.

The role of top impact sieve for particle size inspection is not only reflected in efficient screening, but also in improving the accuracy and repeatability of test data, providing reliable data support for process adjustment, product classification and quality determination. It is particularly suitable for particle size analysis tasks under standardized, batch and laboratory conditions, and is an indispensable testing tool in many industries.

What is the wet sieving process?

Wet sieving process is a sieving process assisted by a liquid (usually water or a solution containing a dispersant) to more effectively...

Fines content tester can be defined as an instrument used to quantitatively determine the content of fines powder components of a specific fineness...

Micro silica powder particle size analysis test sieve

Micro silica powder, also known as silica fume, is an ultrafine active silica material with a very small particle size, usually between 0.1-0.3 microns, which...

Jul 07, 2025

Top impact sieve for particle size inspection

Top impact sieve for particle size inspection is set with 2-5 layers of screens. Mesh size of each la...

Jul 07, 2025

Standard Test Method for Particle-Size Analysis of Soils

Soil particle size analysis mainly uses sieving method (applicable to coarse-grained soil, such as gr...

Jul 05, 2025

What is the price of electromagnetic screen vibrator

The price of electromagnetic sieve vibrators is affected by the model, power, control system, core co...

Jul 05, 2025

Electromagnetic powder ultrasonic test sieve

Electromagnetic powder ultrasonic test sieve mesh covers 20-500 mesh, made of stainless steel, with u...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap