Wednesday June-04 2025 15:59:55

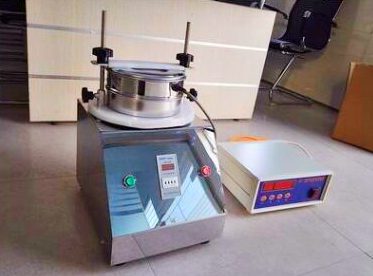

The ultrasonic sieve test for juice powder is a fine screening equipment designed for delicate, moisture-absorbing, and agglomerated materials such as juice powder. Juice powder usually has the characteristics of small particle size, high sugar content, easy to generate static electricity and agglomeration.

Traditional screening equipment is prone to problems such as mesh blockage and low screening efficiency. The ultrasonic sieve test is equipped with an ultrasonic system on the basis of an ordinary vibrating screen. By superimposing high-frequency micro-vibration on the screen, it effectively breaks up the agglomerated materials and improves the screening penetration rate. This equipment generally adopts a 1-3 layer screen structure, which can achieve multi-level screening and impurity removal of juice powder, such as grading fruit powder of different fineness into coarse powder, fine powder and ultrafine powder to meet different process requirements.

Ultrasonic sieve test for juice powder: The ultrasonic vibration system transmits high-frequency mechanical waves to the screen, so that the juice powder particles form a micro-suspension state on the screen surface, effectively solving the problems of agglomeration and blocking of ultrafine powders caused by static electricity and viscosity. Its screening accuracy can reach 25μm, and the efficiency is increased by 2-10 times. It is especially suitable for the grading of 200-600 mesh ultrafine powders such as juice powder and coffee powder, meeting the needs of high precision and low residue.

Juice filter screen: It mainly relies on the three-dimensional motion (horizontal/vertical/inclined vibration) of the vibration motor to drive the screen, and realizes solid-liquid separation through screens of different apertures to remove large particle impurities such as pulp and fiber in the juice. Its technical core is to improve the clarity and taste of juice. It is mainly used for front-end processing of juice production lines, such as pineapple juice and pineapple juice processes, to remove pulp residues through screening and filtration to improve the purity of juice.

The ultrasonic sieve test combines the ultrasonic system with the vibration motor system to superimpose high-frequency, low-amplitude ultrasonic vibrations (usually 18-40kHz) on the screen. This vibration keeps fine powders such as juice powder in suspension, effectively prevents screen blockage, and solves problems such as adhesion, friction, and wedging, thereby improving screening efficiency and accuracy.

Basics of vibration screening: The vibration motor generates a three-dimensional motion pattern, which causes the screen placed on it to vibrate, so that the material jumps forward in a spiral on the screen surface. This mode of movement helps to disperse particles of different sizes and gradually pass through the screen.

The addition of the ultrasonic system: This system generates high-frequency, low-amplitude ultrasonic vibration waves and evenly distributes these vibrations on the surface of the screen. Ultrasonic vibration can not only increase the screening efficiency, but also effectively prevent fine particles from clogging the sieve holes, the so-called "blocking" phenomenon. This is especially important for materials like juice powder that are delicate and easy to agglomerate.

Screening process: The juice powder is placed above the sieve, and with the action of vibration and ultrasound, the material begins to move on the sieve surface. Particles smaller than the sieve aperture will smoothly pass through the sieve holes and fall, while larger particles remain on the sieve surface, and finally separate particles of different sizes. This process is critical to ensure the fineness and purity of the juice powder.

The mesh number selection of ultrasonic sieve test for juice powder should be determined according to its particle fineness and screening requirements. It is usually recommended to use a sieve between 100 mesh and 325 mesh, as follows:

80-120 mesh: suitable for coarse screening of juice powder, often used to remove larger particles or impurities, suitable for preparing juice powder products with strong granularity, such as instant beverage powder. This mesh number has high screening efficiency and large output.

120-200 mesh: suitable for medium-fine screening, producing medium-fine juice powder, widely used in food additives or instant juice powder. This range can balance screening accuracy and output, and reduce agglomeration.

200-400 mesh: recommended for high-quality juice powder, such as high-end solid beverages or nutritional supplements, requiring fine powder and good solubility. Ultrasonic vibration can effectively prevent fine powder from clogging the screen.

400-600 mesh: used for screening of ultra-fine juice powder, suitable for special purposes (such as pharmaceutical grade or high-end food ingredients), but the screening difficulty is higher, requiring high-performance ultrasonic system support, and the output is low.

The juice powder ultrasonic sieve test is mainly used for precise screening of moisture-absorbing, lightweight, fine-particle powder materials such as juice powder, and is often used in the quality control links of food processing, solid beverages, instant powders and other industries. In actual use, the equipment effectively solves the problems of easy clogging and adhesion of juice powder during the screening process by superimposing high-frequency ultrasonic vibration on the screen, and can improve the screening accuracy and efficiency. For example, in the production process of juice powder, manufacturers need to classify the dried powder according to the particle size to ensure that the product particles are uniform and have high solubility, which meets the requirements of product packaging and market circulation. The ultrasonic test sieve can perform particle size analysis and impurity detection on different batches of juice powder samples, which helps to optimize the production formula and control product quality. It is an indispensable equipment for fine screening and experimental testing of juice powder.

The ultrasonic sieve test for juice powder provides an efficient and accurate solution for the screening of juice powder by combining vibration and ultrasonic technology. It is an indispensable key equipment in the production process of juice powder, which can significantly improve production efficiency and product competitiveness. It is used for fine screening and quality control of juice powder, realizes efficient and accurate grading, meets the specific needs of different downstream products, and ensures that the stability, appearance and flavor of the final product are in the best state.

What is the wet sieving process?

Wet sieving process is a sieving process assisted by a liquid (usually water or a solution containing a dispersant) to more effectively...

Fines content tester can be defined as an instrument used to quantitatively determine the content of fines powder components of a specific fineness...

Micro silica powder particle size analysis test sieve

Micro silica powder, also known as silica fume, is an ultrafine active silica material with a very small particle size, usually between 0.1-0.3 microns, which...

Agricultural gruesos Test sieves

Agricultural gruesos test sieves are experimental equipment used for particle size analysis, grading and testing of agricultural soil, gruesos...

Stainless steel frame and woven cloth

The test sieve is a laboratory equipment used for particle size analysis. Its core components usually include a stainless steel frame and woven cloth (also called a sieve)...

Wheat flour ultrasonic test sieve

Wheat flour has the characteristics of easy agglomeration, light specific gravity, and easy adhesion due to electrostatic adsorption. Ordinary...

Jun 04, 2025

Ultrasonic Sieve test for Juice Powder

Ultrasonic sieve test for juice powder is suitable for screening high-sugar juice powder that is easy...

Jun 04, 2025

Wheat flour ultrasonic test sieve

Wheat flour is easy to clog ordinary sieves due to easy agglomeration and electrostatic adsorption. T...

May 30, 2025

Millet sand ultrasonic test sieve

Millet sand ultrasonic test sieve is suitable for fine powder materials above 400 meshes, which can a...

May 29, 2025

200 micron brass mesh soil sieve set with frame

200 micron brass mesh soil sieve set with frame is a soil sieving tool with a pore size of 200 micron...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap