![[field:title/]](/uploads/allimg/250321/2-2503211H150201-lp.png)

Vitamin powder test sieve is a device specially used for screening, grading and analyzing the particle size of vitamin powder. It is widely used in pharmaceutical, food, chemical and other industries to ensure that the product meets the standard particle size distribution requirements.

Number of layers: 1-8 layers

Screening particle size: 0.025mm-20mm

Features: Smaller size, higher precision, suitable for small batch sample processing

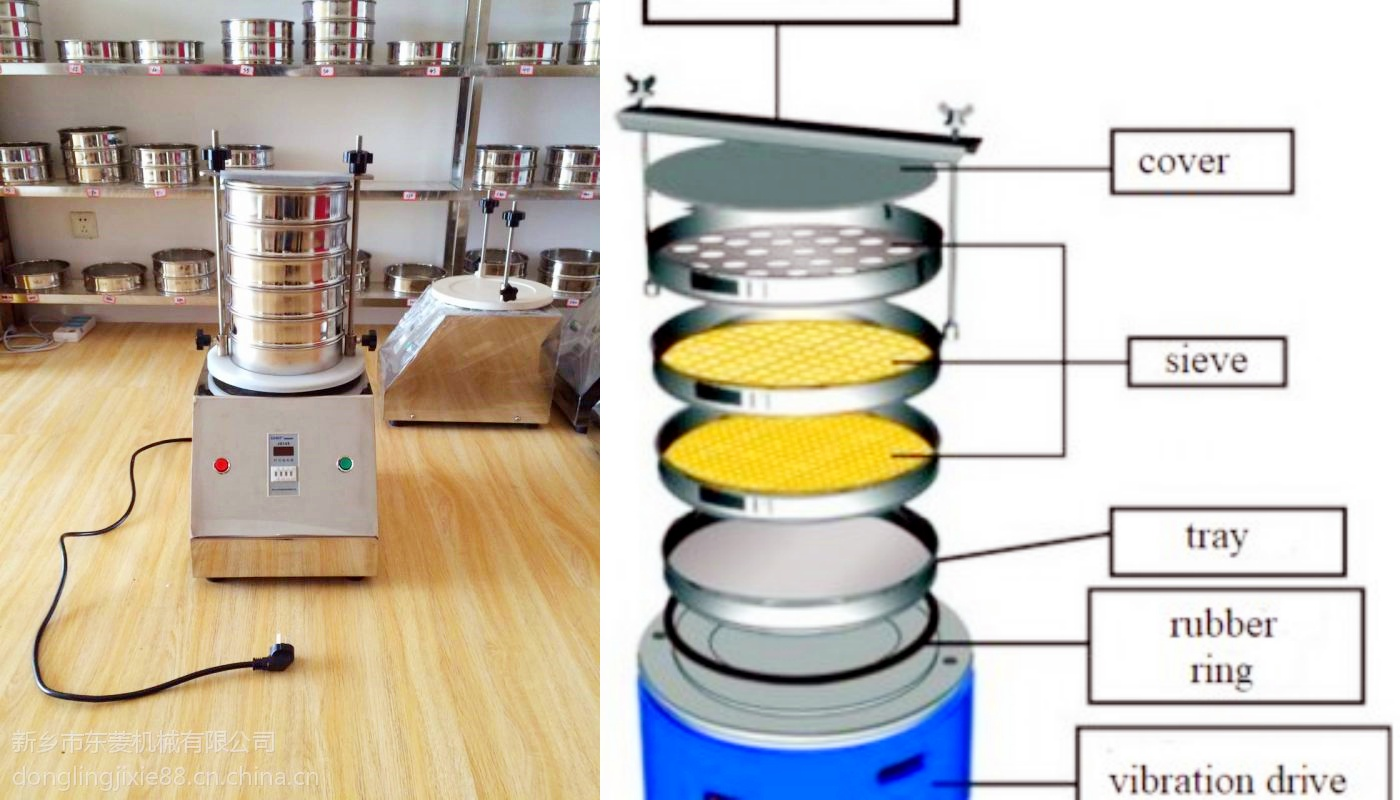

Structural composition: screen frame, screen, vibration motor, ultrasonic system (optional), control system, base and bracket.

Port: Any port in China (Mainland)or as you need.

|

Quantity(sets) |

1-2 |

>2 |

|

Delivery time(days) |

5 |

To be negotiated |

Vitamin powder test sieves usually refer to equipment used to sieve vitamin powders in laboratories or small-scale tests, mainly for analyzing the particle size distribution of vitamin powders, quality control or research and development purposes.

Particle Size: Vitamin powder particle size is usually between 10-500μm, depending on the production process.

Properties: Hygroscopic, medium fluidity, may be slightly sticky or agglomerate.

Requirements: The test sieve must ensure high-precision classification, avoid contamination, and meet food or pharmaceutical grade hygiene standards.

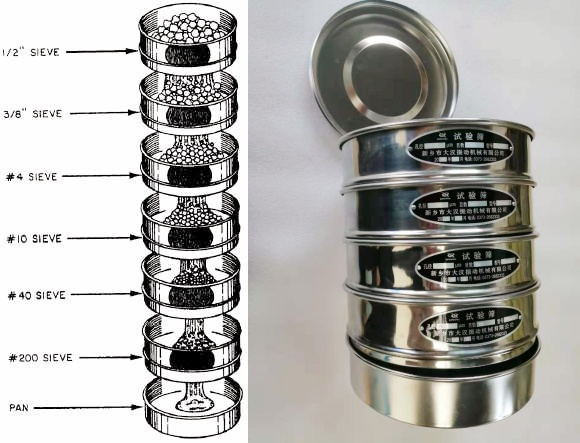

The test sieve is based on the principle of vibration screening and consists of multiple layers of standard sieves (different mesh sizes), sieve frames and vibration devices.

Process:

①Place the vitamin powder sample on the top sieve.

②The vibration motor drives the sieve frame to produce horizontal and vertical vibrations, and the vitamin powder moves on the sieve.

③The vitamin powder particles smaller than the sieve holes pass through layer by layer and are finally collected in each layer of sieve according to the particle size distribution.

|

Test sieve types |

pictures |

features |

applicable scenarios |

|

Vitamin powder slapping sieve |

|

①Suitable for powders of different particle sizes ②Suitable for small batch screening |

Laboratory particle size analysis, quality control of small-scale production |

|

Vitamin powder top impact sieve |

|

①Uniform top impact force, high screening efficiency ②Suitable for medium batch screening |

Laboratory research and development, screening needs of small and medium-scale production |

|

Vitamin powder ultrasonic test sieve |

|

Suitable for ultrafine powder screening (below 10μm) |

Screening of ultrafine vitamin powders, high-precision quality control, screening of easily agglomerated powders |

|

Vitamin powder magnetic suspension test sieve |

|

①No mechanical contact, reduce wear ②Vibration frequency can be precisely controlled |

High-precision particle size analysis, laboratory research and development, screening of vibration-sensitive vitamin powders |

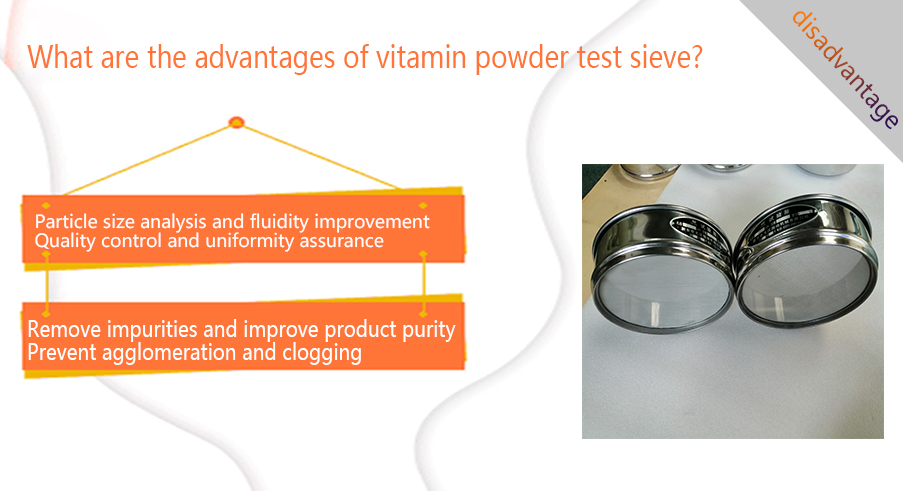

1. Particle size analysis and fluidity improvement

The uneven particle size distribution of vitamin powder will lead to poor fluidity, and problems such as agglomeration and bridging are prone to occur during transportation. The vitamin powder test sieve can accurately measure the particle size distribution of vitamin powder and understand the proportion of particles of different particle sizes.

2. Quality control and uniformity assurance

The uneven particle size distribution of vitamin powder will lead to uneven mixing, affecting the content and stability of the active ingredients of the product. Vitamin powder test sieve can detect the particle size consistency of different batches of vitamin powder to ensure stable product quality.

3. Remove impurities and improve product purity

Vitamin powder test sieve can remove foreign matter, coarse particles and uncrushed agglomerates, improve the purity of vitamin powder, and can also meet the strict requirements of the pharmaceutical and food industries for powder fineness and purity.

4. Prevent agglomeration and clogging

Vitamin powder test sieve can effectively reduce powder adhesion and adhesion and prevent screen clogging. Operation in a low humidity environment, combined with anti-static treatment, reduces the risk of powder agglomeration.

Coarser particles (40-80 mesh): suitable for vitamin powders that require better fluidity, reduce dust flying, and facilitate subsequent processing.

Medium particles (100-200 mesh): suitable for most vitamin powders, such as raw materials before tablets and capsules are filled. Improve mixing uniformity and ensure stable product quality.

Ultrafine particles (200-400 mesh): suitable for special purposes, such as instant preparations, spray-dried powders, to improve bioavailability and absorption effects. Suitable for drugs and functional foods that require strict control of particle size distribution.

|

Mesh number |

sieve aperture |

applicable particle size range |

application scenario |

|

20 mesh |

850μm |

coarse powder (>500 μm) |

preliminary screening of large-particle vitamin powder |

|

40 mesh |

425μm |

coarse powder (150-500 μm) |

applicable to vitamin powder with larger particles, such as some crystalline or granular vitamin C, B vitamins, etc. |

|

60 mesh |

250μm |

medium powder (44-150 μm) |

applicable to coarser powder, ensuring certain fluidity and reducing dust |

|

80 mesh |

180μm |

medium powder (44-150 μm) |

applicable to conventional vitamin powder, such as powder before tablet and capsule filling |

|

100 mesh |

150μm |

fine powder (10-44 μm) |

applicable to most vitamin powders, ensuring particle uniformity and improving mixing uniformity |

|

120 mesh |

125μm |

fine powder (10-44 μm) |

Sieving of high-precision vitamin powder |

|

200 mesh |

75μm |

Ultrafine powder (0.5-10 μm) |

Suitable for ultrafine powder, such as micronized vitamin A, D, E and other fat-soluble vitamins |

|

325 mesh |

45μm |

Ultrafine powder (0.5-10 μm) |

Sieving of ultrafine vitamin powder. |

|

400 mesh |

38μm |

Ultrafine powder (<0.5 μm) |

Suitable for ultrafine powder, meeting high-precision requirements |

Vitamin powder test sieve is widely used in food, pharmaceutical, health care products and agriculture industries. It can not only be used for product quality control, but also for production process optimization and new product development. Through the test sieve, the particle size of vitamin powder can be accurately controlled to ensure the quality and stability of the product.

|

Parameter |

Typical value/range |

Description |

|

Sieve mesh |

20–1000 mesh |

Aperture 850μm to 15μm, covering the particle size range of vitamin powder |

|

Sieve diameter |

200mm or 300mm |

200mm is the laboratory standard, 300mm is suitable for slightly larger samples |

|

Number of layers |

1–8 layers |

Multi-layer design can classify multiple particle sizes at the same time |

|

Vibration frequency |

1400–3000 times/minute |

Adjustable, affecting the screening speed |

|

Power |

0.12–0.37kW |

Low energy consumption, suitable for laboratory use |

|

Material |

Stainless steel (304/316L) |

Corrosion-resistant, in line with food/medical and health standards |

|

Sample capacity |

50 g–1 kg |

Single processing volume is small, depending on the model |

|

Noise |

<75dB |

Quiet operation, suitable for indoor environment |

Dahan Machinery is a professional screening equipment manufacturer that provides various types of test sieves, including slap sieves, top impact sieves, ultrasonic test sieves and magnetic suspension test sieves, etc. It focuses on providing high-quality screening solutions for the food, pharmaceutical, chemical and other industries.

Test Analysis Sieve is a sieve for separating mixtures. It mainly makes the mixture of particles of different...

Sieve Analysis Test is mainly used for grading the particle size composition of various powder materials,...

Soil Test Sieve can be used for soil grading, screening, analysis, testing, filtering various soils, widely used...

Standard Sieves standard sieve is a tool for particle size classification and particle size detection of material...

Vitamin powder slapping screen

Vitamin powder slapping screen is a device used to sieve vitamin powder. It achieves sieving through vibration and slapping action. It is often used to remove impurities, grade part...

Stainless steel corn grits test sieve

Stainless steel corn grits test sieve is a screening device specially used for particle size analysis and quality control, and is widely used in food, chemical, pharmaceutical and o...

Industrial Ultrasonic Metal Powder Test Sieve

Industrial ultrasonic metal powder test sieve is mainly used in laboratories or small batch production to analyze and classify fine particle materials such as metal powder and alloy...

Ultrasonic test sieve for wheat flour

Ultrasonic test sieve for wheat flour is a special device that combines ultrasonic technology with traditional screening principles to efficiently screen wheat flour. The device can...

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap