Wednesday July-02 2025 14:45:58

Water Test Sieve, also known as wet screening, is a special particle size analysis method that is mainly used to determine the fineness of materials that are difficult to handle in conventional dry screening. The core of this method is to use water flow as a medium to assist screening, especially for ultrafine powders and particles that are easy to agglomerate, highly static, sticky or have a high mud content.

This method is usually used to determine the content of components finer than a specific mesh in materials such as cement, slag, and soil, such as the 45 micron (325 mesh) sieve residue of cement or the mud content of sand and gravel.

Dry screening method relies on mechanical vibration to make particles pass through the sieve, which is suitable for relatively dry and non-sticky samples; water test sieve relies on the scouring force, shear force and gravity of water flow to separate and disperse samples, which is more suitable for powders that are easy to agglomerate and have high viscosity (such as cement), and can avoid the difficulty of screening particles due to static electricity or adhesion.

Water test sieve is more suitable for samples that are moist, easy to absorb water or have high water content (such as wet sand, mud), as well as powders with high viscosity and easy to agglomerate (such as cement, clay, paint pigments). In addition, for fine particles (especially micro powders less than 0.1mm, such as cement 80μm screening) and samples that are prone to static electricity, water flow can eliminate the influence of static electricity and screen more thoroughly.

Dry screening method is more suitable for dry, non-sticky particles (such as quartz sand, dry ore crushing materials), and medium and coarse particles (aggregates larger than 0.1mm). However, it should be noted that samples that are sensitive to water or easily react to water (such as cement dry screening initial inspection) must be screened by dry screening, otherwise it will affect the accuracy of the test.

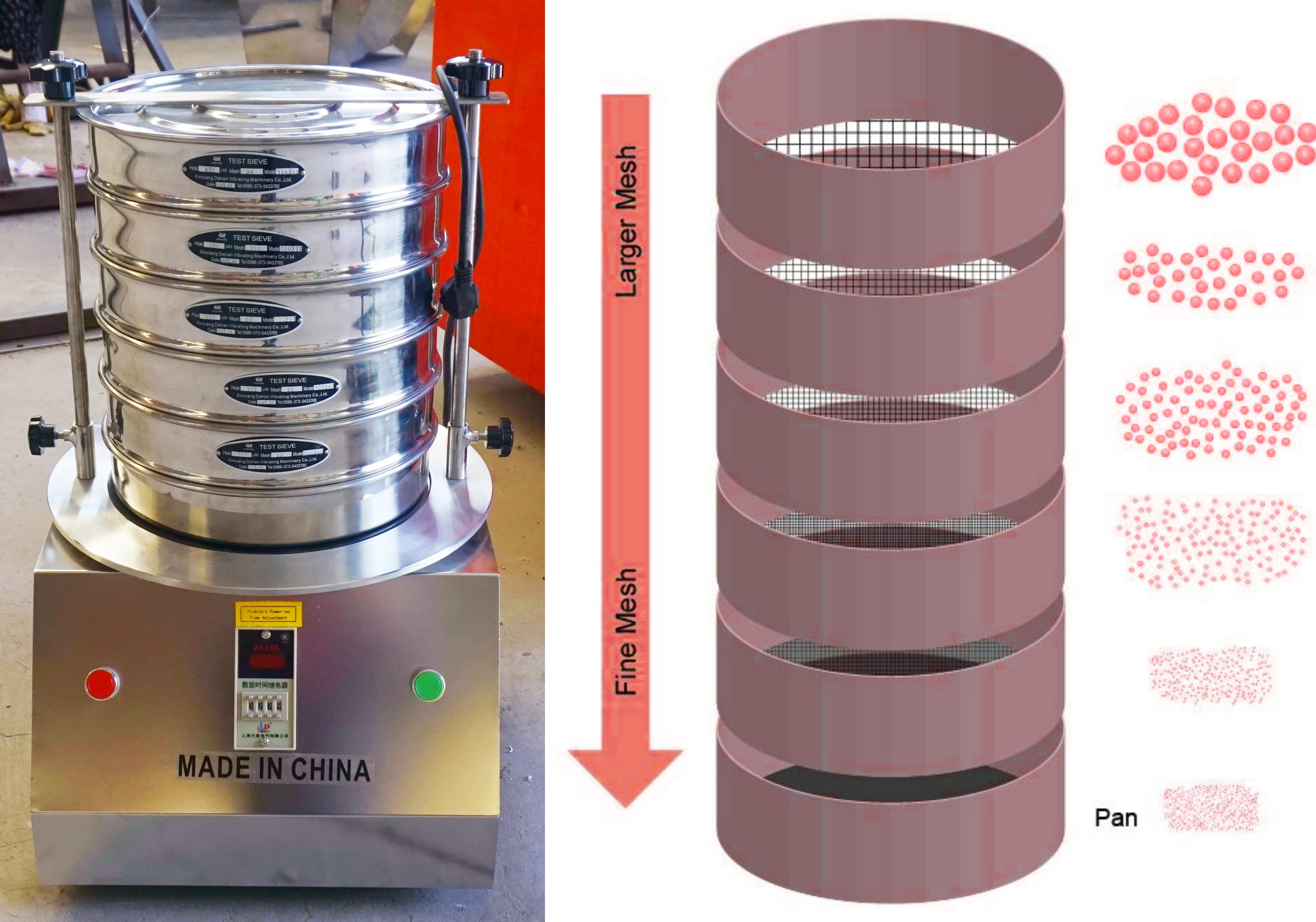

During the wet screening process, the sample is placed on the test sieve and flushed with a water flow of a specified pressure. The water flow not only disperses the sample, but also helps fine particles pass through the sieve holes through mechanical flushing force. Particles smaller than the sieve holes enter the collection tray with the water flow, while particles larger than the sieve holes remain on the sieve (screen residue). By drying and weighing the screen residue, the percentage of particles of different particle sizes can be calculated, thereby obtaining the particle size distribution of the sample.

|

Model |

sieve frame diameter (mm) |

sieve mesh range (mesh) |

sieve material |

sieve frame material |

screening method |

application range |

|

WS-200 |

200 |

10-200 |

304 stainless steel wire mesh |

304 stainless steel frame |

vibration |

laboratory water sample particle screening |

|

WS-300 |

300 |

10-150 |

304 stainless steel wire mesh |

304 stainless steel frame |

vibration |

medium sample volume screening |

|

WS-450V |

450 |

10-100 |

316 stainless steel wire mesh |

316 stainless steel frame Stainless steel frame |

Mechanical vibrating screen |

Large sample volume, on-site and laboratory screening |

|

WS-300S |

300 |

20-200 |

304 stainless steel wire mesh |

304 stainless steel frame |

Ultrasonic assisted vibrating screen |

Fine particles and high-precision screening |

|

WS-250 |

250 |

10-150 |

304 stainless steel wire mesh |

304 stainless steel frame |

Manual shaking screen |

Small water sample screening |

Water test sieves are not suitable for samples that dissolve or react chemically in water because this will change the original particle size of the sample. Strong water flow may cause further crushing of fragile particles, resulting in a smaller measured particle size than the actual size, which is not suitable for the analysis of certain specific materials. During the washing, transfer and drying process, there may be a small amount of sample loss, especially for very fine particles, which will affect the accuracy of the final result. Insufficient flushing time will lead to incomplete screening, while too long flushing time may cause wear on the particles and change their particle size distribution

Water test sieves, which are often called wet screening, have irreplaceable applications in many industrial and scientific research fields. It is particularly suitable for materials that are difficult to handle with traditional dry screening. Water is used as a medium to help disperse particles and clean the sieve holes, thereby obtaining more accurate particle size analysis results.

① Environmental water quality monitoring: suspended particle detection in natural water bodies such as rivers, lakes, and reservoirs, and particle monitoring before and after treatment of industrial wastewater and domestic sewage

② Sewage treatment process control: sludge particle size distribution analysis, solid particle removal efficiency detection during sewage treatment

③ Industrial circulating water detection: impurity particle screening in cooling water systems, suspended particle monitoring in industrial production water, to prevent equipment blockage and corrosion

④ Scientific research and laboratory analysis: particle morphology and particle size analysis in water quality research, particle screening experiments for water treatment technology research and development

Water test sieves are mainly used for screening and particle size analysis of solid particles in water samples. They have a wide range of applications. By quickly and intuitively separating particles of different particle sizes in water, they help various industries to conduct water quality analysis and process optimization. They are important tools for water quality testing and solid-liquid separation.

Telescopic belt conveyor

Telescopic belt conveyors can provide automated loading and unloading services for any type of distribution center and cargo transfer center,...

Grain moving machine augers

Grain moving machine augers are mechanical devices used in agriculture to efficiently move grain (corn, wheat, soybeans, or oats) from one...

Sewage treatment material screw conveyor

Sewage treatment material screw conveyor is a kind of equipment specially used for conveying solid or semi-solid materials (such as sludge, screen...

Z-type bucket elevator for bentonite transportation

The Z-type bucket elevator for bentonite transportation is specially designed and manufactured for the characteristics of bentonite. It is an efficient...

Farmyard manure screw conveyor

A farmyard manure screw conveyor is a device specially used for cleaning and conveying animal manure in farms. It is mainly used to convey animal manure, manure residue...

Rice bran swing screen

Rice bran swing screen is usually equipped with 2 to 5 layers of screens, and the commonly used screening mesh is 10 to 80 meshes, which can simultaneously achieve operations such...

Jul 02, 2025

Water Test Sieve is a method of particle size analysis using water flow as a medium. It is mainly use...

Jul 01, 2025

Application sand Specifications of Agricultural Soil Test Sieves

The agricultural soil test sieve is a screening device for accurately grading soil particles, which i...

Jun 30, 2025

Top impact sieve for particle size inspection

The top impact sieve effectively realizes the particle size classification and quantitative analysis ...

Jun 28, 2025

The size of soil sieve mainly refers to the sieve frame diameter (commonly used 200mm, 300mm, etc.) a...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap