![[field:title/]](/uploads/250401/2-25040109511Y92.jpg)

Wet sieving is a procedure used to evaluate the particle size distribution or gradation of granular materials. It is commonly used to separate granular materials and process materials with high moisture content.

International standard: ISO3310-1:1990 R20/3, R20, R40/3 series

Mesh size: 20 microns - 5 mm

Diameter: 3", 8", 12"

Height: 4 inches, 8 inches

Material: Stainless steel, brass

Application: Suitable for wet processing, where high concentrations of fine particles tend to stick together and cannot be separated by mechanical shaking alone, such as aggregates, clay, mud, silt, etc.

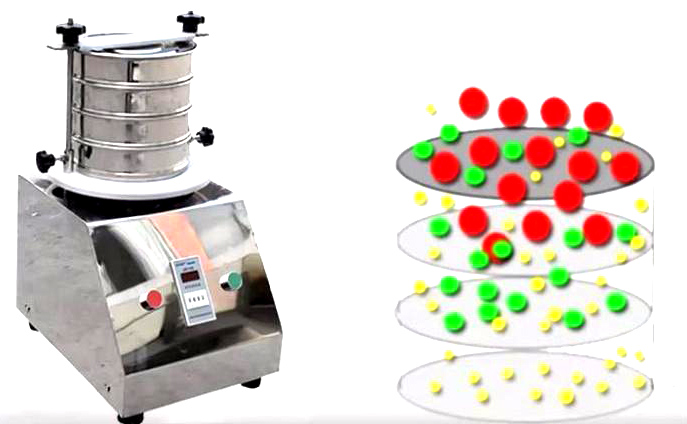

Wet Sieving is a procedure used to evaluate the particle size distribution or gradation of granular materials. It is mainly used to deal with materials that are easy to agglomerate, sticky or contain moisture. Unlike dry sieving, wet sieving assists sieving by adding liquid (usually water) to make the material pass through the screen more easily, thereby improving sieving efficiency and accuracy.This process not only reduces the probability of material clogging the sieve holes, but also reduces mutual interference between particles, improving the efficiency of screening operations. At the same time, it ensures that the final particle size analysis results are more in line with the actual grading of the material, providing accurate data support for subsequent production processing, quality control and other links.

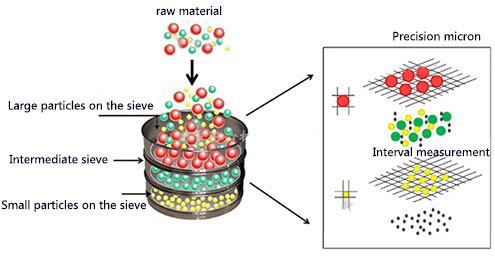

Common wet sieving sieves range from 20 to 400 mesh (approximately 850 µm to 38 µm), with the specific choice depending on the sample particle size distribution and experimental requirements. Typically, 20–100 mesh is used in coarse sieving, while 200–400 mesh is commonly used in fine sieving or sediment analysis to ensure sufficient particle dispersion and accurate sieving results.

| Aspects | Details |

| Use | Analyze materials that are difficult to screen dry (e.g., high moisture, fine particles) |

| Process | Rinse the sample with water until the liquid runs clear, ensuring that the sample remains unchanged |

| Benefits | Increase accuracy, adaptability to various conditions, and effective sample cleaning |

| Equipment | Accessories such as wet screens, stainless steel options, and aggregate washers |

| Applications | Construction, aggregate processing, and laboratory analysis |

| Notes | Select the appropriate liquid, adapt to environmental conditions, and maintain the equipment |

Wet Sieving uses the pore size of the screen to separate materials of different particle sizes. Liquid is added to disperse the materials in the liquid, reducing particle agglomeration. Liquid can disrupt the aggregation of fine particles caused by static electricity or van der Waals forces, improving screening efficiency. The liquid can also wash away impurities adhering to the surface of the particles, improving screening accuracy. Furthermore, wet sieving effectively avoids the problem of screen clogging that can easily occur during dry sieving of fine particles, making it suitable for screening operations involving such materials.

| Item | Parameter Description | Typical Range / Value | Remarks |

|---|---|---|---|

| Equipment Model | Common instrument models | Fritsch ANALYSETTE 3 PRO | Functionality varies slightly by model |

| Sieving Method | Vibration + water-wash wet sieving | Vertical or 3D vibration combined with water flow | Improves separation efficiency and prevents clogging |

| Screen Diameter | Standard screen diameter | Φ75 mm, Φ100 mm, Φ200 mm, Φ300 mm | Selected based on sample particle size and capacity |

| Screen Material | Stainless steel / brass / nylon mesh | SUS304 / SUS316L | Must be corrosion-resistant and easy to clean |

| Aperture Size Range | Minimum/Maximum | 20 μm – 4 mm | Custom apertures available |

| Sample Load | Sample amount per run | 50 g – 3 kg (depending on screen diameter) | Uniform loading prevents bias |

| Vibration Frequency | Adjustable vibration rate | 3,000 – 10,000 rpm | High frequency promotes fine particle separation |

| Vibration Amplitude | Vertical / horizontal amplitude | 0.5 – 3 mm (digital adjustable) | Adjusts sieving precision and speed |

| Water Flow Rate | Controlled water flow | 0.2 – 1.5 L/min (adjustable) | Prevents screen clogging |

| Time Control | Electronic timer | 1 – 99 min (digital setting) | Automatic stop function |

| Control System | Touchscreen / knob control | Digital display of frequency, time, water flow | Integrated smart control |

| Sample Type | Applicable materials | Soil, fly ash, mineral powders, metal powders, building materials, pharmaceutical granules, etc. | Especially suitable for cohesive materials |

| Protection Rating | Water resistance | IP54 – IP65 (depending on model) | Suitable for wet environments |

| Power Supply | Voltage / Power | AC 220 V / 50 Hz / 250 W | Optional 110 V version |

| Dimensions | Device footprint | 400 × 350 × 650 mm | Portable or floor-standing design |

| Weight | Net weight | 25 – 60 kg | Depends on number of screens |

| Optional Accessories | Accessories | Water recirculation unit, vacuum filtration bottle, sample divider, collection tray, etc. | Improves test accuracy and efficiency |

| Compliance Standards | International standards | ISO 3310 / GB/T 6003 / ASTM E11 | Screen precision standards |

| Features | Wet sieving | Dry sieving |

| Applicable materials | Materials that are easy to agglomerate, sticky, and contain water | Dry materials with good fluidity |

| sieving medium | Liquid (such as water) | None |

| Equipment requirements | Corrosion resistance, spraying device, drainage device | Ordinary vibrating screen |

| Subsequent processing | Drying or liquid recovery is required | No additional processing is required |

| sieving efficiency | High, especially suitable for sticky materials | Suitable for dry materials |

Wet sieving can be used to remove fine particles that are difficult to separate by dry sieving before routine drying and sample testing. Wet sieving is particularly suitable for solid materials that are insoluble in water and unaffected by water (for example, solids that swell when exposed to water are not suitable) and remain stable when heated to 110°C.

Wet sieving is an ideal pre-treatment method when dealing with samples that contain a lot of particulate matter and fines that are sufficient to prevent sieving. This is because fines tend to clump together, causing inaccurate sieving results. Wet sieving is also suitable for direct measurement of particle size in certain specific materials, including:

Soils and mineral aggregates rich in fine particles; friable but water-insoluble materials such as coal or other minerals; lightweight foundations; sludges and glazes; kaolin and fillers; abrasives and micronized materials.

In construction scenarios, wet screening is often used to determine the fineness of cement and other raw materials. In aggregate processing, this method is used to clean rock and other aggregates to remove clay and silt and ensure accurate particle size measurement. In laboratory analysis, wet screening is also used to analyze fine powders and materials that are difficult to dry screen.

Wet sieving usually has two purposes: one is to determine the amount of material remaining on a specific sieve, and the other is as a sample pretreatment step to facilitate easier or more accurate particle size analysis. In simple terms, wet sieving can be used to directly measure how many particles of different sizes there are; wet sieving can also be used to pre-treat samples to make subsequent particle size analysis more accurate; which wet sieving method you choose depends on what results you ultimately want to achieve.

There are six points to note when wet screening. Avoiding possible errors can make the screening effect more accurate and improve efficiency.

Initial weight: Before you begin wet sieving, be sure to record the total weight of the dry sample, as this data will be used in subsequent calculations.

Soaking: If time permits, it is best to soak the sample for a period of time first. This helps soften lumps and makes the wet sieving process smoother.

Spraying water: During sieving or stirring, use a nozzle or sprayer to evenly spray water on the sample to ensure that the sample is fully wetted.

Water pressure: Control the water pressure and use a gentle, steady stream of water to avoid washing away the sample.

Sample loss: A small amount of sample may be lost during wet sieving, such as being washed away during stirring or decanting, or getting stuck in the gaps of the sieve.

Trade-offs: Despite the small amount of loss, wet sieving is generally more accurate and efficient than dry sieving, especially when dealing with certain special samples.

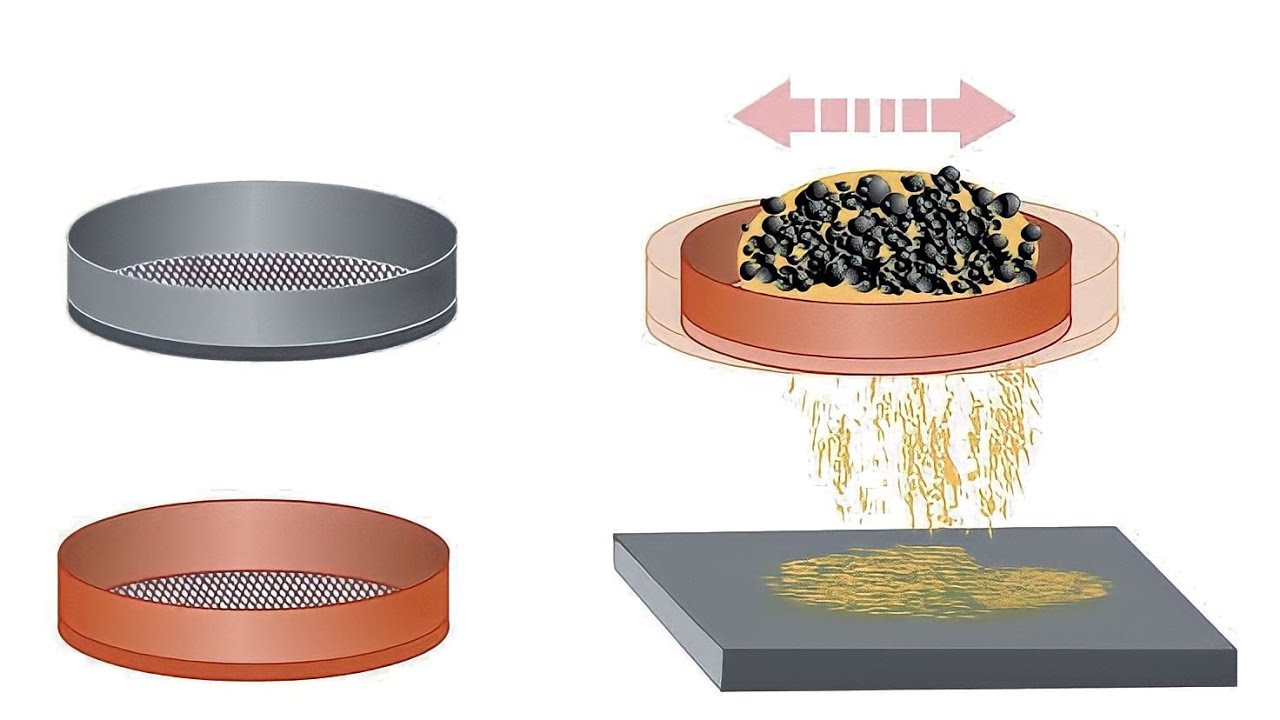

Conventional wet screening equipment usually consists of three parts: wet-wash filter screen, stainless steel mesh and accessories. The relevant equipment can be replaced according to the actual characteristics of the screened material.

Wet Wash Screens: These screens have a deep screen frame to prevent overflow and have drainage holes to handle wash water. Some models also come with replaceable screen assemblies for convenience.

Stainless Steel Options: Stainless steel screens are durable and corrosion-resistant, suitable for repeated use in the wet sieveing process.

Accessories: Aggregate washers and other accessories are available to automate the washing process, increasing efficiency and consistency.

Wet Sieving is a method of sieveing with the aid of liquids, which is particularly suitable for materials that are prone to agglomeration, sticky or contain water. Although wet sieveing equipment is expensive and the subsequent processing is complicated, its efficient sieveing effect and wide applicability make it widely used in the fields of food, chemical industry, mining, etc.

What is the wet sieving process?

Wet sieving process is a sieving process assisted by a liquid (usually water or a solution containing a dispersant) to...

How do you perform wet sieving

Wet sieving test is a method of separating coarse and fine particles of materials with water or other liquids...

What is the difference between wet sieving and dry sieving

he sieving test is divided into wet sieving test and dry sieving test, so what is the difference between wet sieving and dry sieving?...

Five Advantages of Rotap Sieve Shaker

Rotap Sieve Shaker is mainly composed of machine base, sieve and transmission mechanism. It can be equipped with special fixtures, which can be used to clamp 200 test sieves, as wel...

Slap Type Test Sieve is mainly used in laboratories within universities/research institutes/enterprises, with standard test sieves for particle size analysis and detection of granul...

Test sieves for reliable sieve analysis

Test sieves for reliable sieve analysis use high-precision stainless steel test sieves with mesh conforming to international standards, ensuring accurate and reliable particle size ...

Test sieves for reliable sieve analysis

Test sieves for reliable sieve analysis are tools used in laboratories to determine particle size distribution. Test sieves are typically made of durable materials such as stainless...

Laboratory woven wire mesh sieves

Laboratory woven wire mesh sieves are screening tools made of 250 mm stainless steel frame and precision woven wire mesh. The high quality of the equipment ensures reliable screenin...

Sieve Mesh is a metal or non-metal device used to separate materials. Its mesh count refers to the number of holes per square inch. It sorts powders by particle size through vibrati...

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap