Tuesday November-25 2025 16:14:18

Wet sieving concrete is a test method that involves grading freshly mixed concrete or concrete samples through a sieve in water to determine the content and gradation of coarse and fine aggregates. Compared to dry sieving, wet sieving, through the washing action of water, can separate mortar adhering to the surface of the aggregates, making the particle size boundaries clearer and thus improving the accuracy and stability of the sieving results.It is used for quality inspection and mix proportion verification of various types of concrete, including freshly mixed or plastic concrete, high-flowability concrete, concrete that has already partially set, and concrete with high powder content or high viscosity.

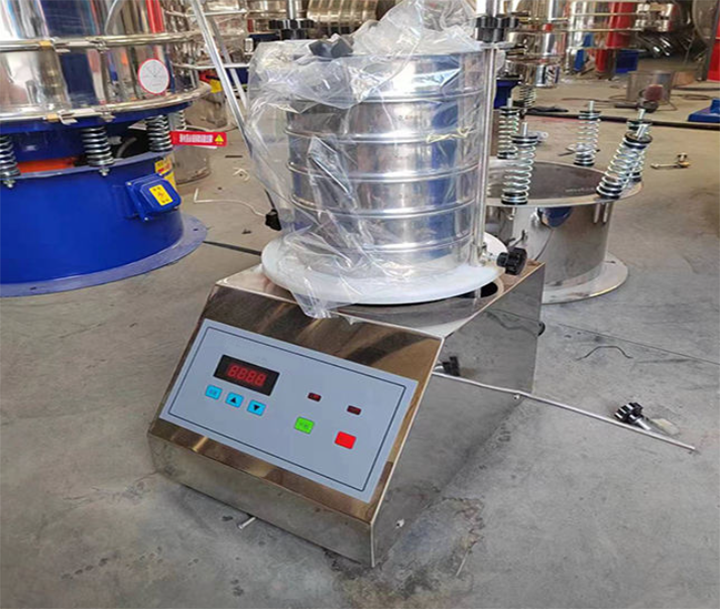

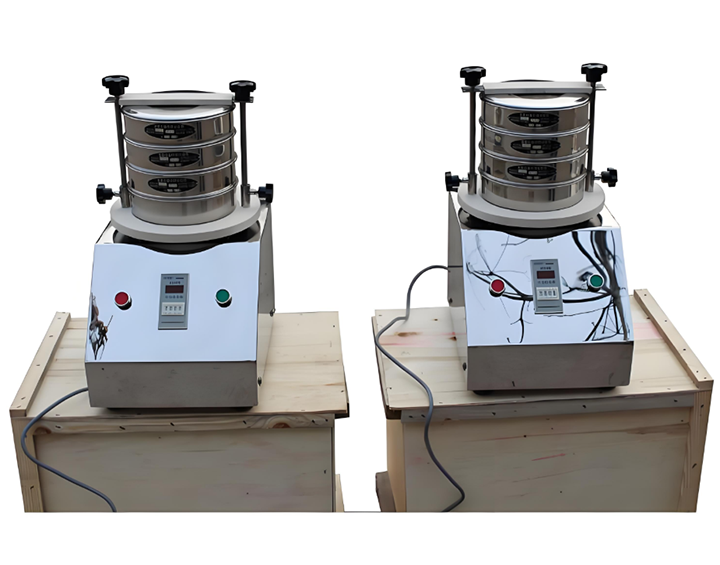

Concrete contains a large amount of mortar and water. If dry sieving is used, the mortar will stick to the sieve mesh walls, leading to incomplete sieving, excessive sieve residue, and affecting accuracy. Wet sieving equipment generally uses a standard vibrating screen, which provides uniform vibration with controllable amplitude. Common sieve materials include stainless steel mesh, copper mesh, or galvanized steel mesh, with stainless steel mesh offering the best corrosion resistance and suitable for long-term water-washed sieving. Depending on the particle size of the material, commonly used sieve mesh sizes include: 4.75 mm, 9.5 mm, and 37.5 mm for coarse aggregates; and 2.36 mm, 600 μm, and 150 μm for fine aggregates and powders.

Take a representative sample from fresh concrete, or crush and sample hardened concrete, and weigh the initial total weight. Place the sample on the top coarse sieve and briefly immerse it in a basin of water to soften any lumps. Then, move the sieve to a test sieve machine, turn on the spray, and gently and continuously rinse the sample with water, allowing it to pass through each sieve layer. Carefully rinse the material retained on each sieve layer into a tray. Place all sieved material, as well as the target material obtained from sedimentation, filtration, and drying in the suspension, into a drying oven to constant weight. Finally, weigh each portion and calculate the percentage of each particle size relative to the total dry weight of the sample to plot a particle size distribution curve and calculate the content of particles smaller than 75 μm.

| Mesh (Mesh) | Opening Size (mm) | Use / Notes |

| 4 | 4.75 | Coarse sand upper limit, coarse aggregate screening |

| 6 | 3.35 | Coarse sand grading check |

| 8 | 2.36 | Common for sand grading, coarse-fine separation |

| 10 | 2.00 | Medium sand screening |

| 12 | 1.70 | Medium sand fine grading |

| 16 | 1.18 | Fine sand grading check |

| 20 | 0.85 | Fine sand fine grading |

| 25 | 0.71 | Fine sand analysis |

| 30 | 0.60 | Very fine sand analysis |

| 40 | 0.425 | Powder/fine particle detection |

| 50 | 0.30 | Powder content analysis |

| 60 | 0.25 | Fine powder classification |

| 70 | 0.212 | Ultra-fine particles |

| 100 | 0.15 | Powder limit and very fine particles |

| 140 | 0.106 | Extremely fine powder analysis |

| 200 | 0.075 | Stone powder content and micro-powder detection |

Accurately determine the moisture content of coarse aggregate: If the entire concrete sample is dried directly, the moisture in the cement paste will also be included, leading to an overestimation of the "aggregate moisture content," which cannot guide production adjustments. Wet sieving separates clean coarse aggregates, and then their moisture content is determined, yielding reliable results.

For testing concrete containing high levels of fine particles: These fine particles clump together during dry sieving, clogging the screen and causing severely distorted results. Wet sieving washes and disperses them, providing accurate results.

For analyzing the actual gradation of fresh concrete: Dry sieving is ineffective, especially when thickeners, viscosity modifiers, or recycled fine aggregates are used.

For investigating concrete quality problems: If concrete exhibits insufficient strength, excessive bleeding, or surface dusting, and the aggregate gradation (especially fine aggregates) is suspected to be substandard, wet sieving is the preferred method for accurate analysis.

Dry sieving relies on screen vibration to directly separate materials, while wet sieving uses water flow to help disperse adhering concrete, resulting in more accurate results. For fresh concrete or mortar, the mortar can clog the screen openings, leading to incomplete sieving. Dry sieving is only effective with dry aggregates, powders, or non-sticky materials. Wet sieving eliminates interference from cement, mineral admixtures, and soil, allowing you to clearly see the true particle composition of the aggregate used, which is crucial for the workability, strength, and durability of concrete.

In wet sieve concrete processing, different equipment can be selected based on the concrete's fluidity and state. Manual screening involves shaking the screen frame and can screen concrete with low fluidity or semi-dry stiffness. Particle separation is achieved through manual beating, mixing, and screening, offering flexibility but low efficiency and high labor intensity. Electric screening equipment can have 1-7 layers of screens and can screen plastic or pumpable concrete. The screen vibration or rotation drive can separate sand, gravel, and impurities, making it suitable for medium to large-scale projects. Ultrasonic screening equipment can screen concrete with high fluidity or containing high-viscosity additives. It uses ultrasonic vibration to prevent mesh clogging, improves screening accuracy, and maintains concrete homogeneity.

Wet sieving concrete, with the aid of water, separates aggregates from mortar and is suitable for fresh concrete and materials with high mud content. Standard wet vibrating screens are water-resistant and wear-resistant, with standard screen frame diameters commonly 200mm or 300mm. The connection between the screen frame and the screen mesh is usually welded or has a locking edge structure to ensure it does not loosen or deform during vibration and wet washing. Screen mesh options include standard woven wire mesh and perforated mesh. Compared to dry sieving, wet sieving solves problems such as screen clogging and adhesion, making it a more reliable method for concrete screening.

Soil sieve analysis is a soil particle size determination method based on the principle of mechanical separation...

Juice Powder Ultrasonic Sieve test

The ultrasonic sieve test for juice powder is a fine screening equipment designed for delicate, moisture-absorbing...

Standard Test Method for Particle-Size Analysis of Soils

Standard Test Method for Particle-Size Analysis of Soils (ASTM D422)aims to accurately determine the size distribution of soil particles...

Size sieve for soil primarily involves the sieve frame diameter and sieve aperture size...

Nov 25, 2025

Wet sieving concrete is a sample pretreatment procedure that removes coarse aggregate from fresh conc...

Nov 24, 2025

Mechanical Sieve Shaker for Particle Analysis

Mechanical Sieve Shaker for Particle Analysis automatically stirs and separates particles. This devic...

Nov 24, 2025

For Laboratory Sieves Price ranges from $100 to $500 USD, and the price varies depending on the sieve...

Nov 22, 2025

laboratory sieve with material

Laboratory sieves with materials include brass, stainless steel, or a brass frame with a stainless st...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap