Thursday October-30 2025 08:53:54

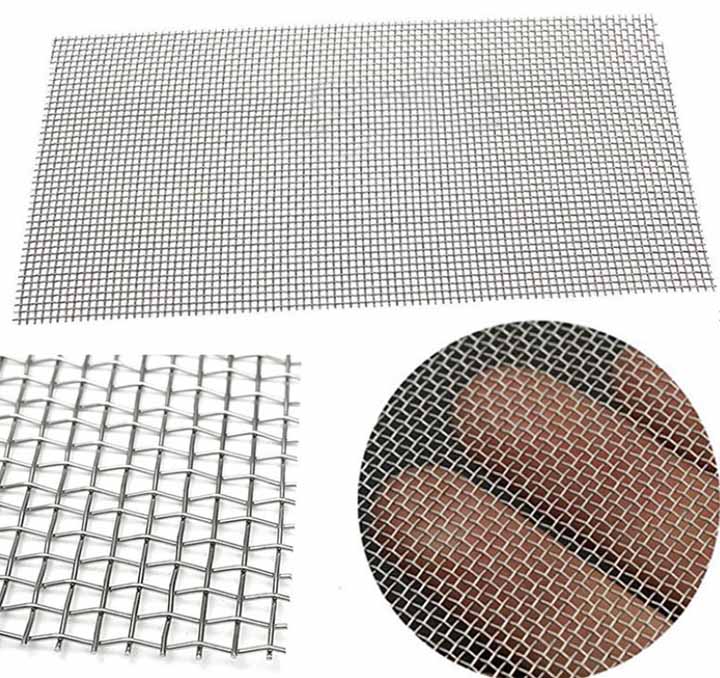

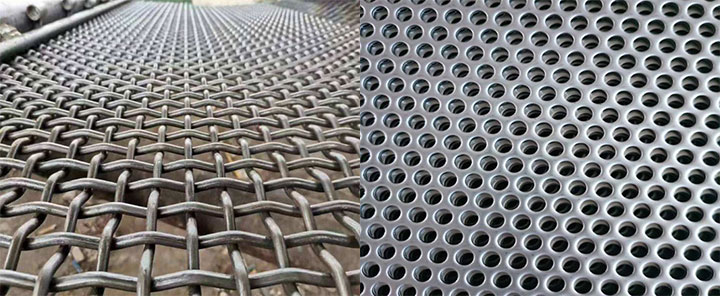

Sieve Mesh is a precision tool made of metal, nylon, or other synthetic materials, with a uniform pore size, used for classifying, filtering, or testing granular, powdery, or slurry materials. Its function is to separate materials based on particle size, thereby achieving particle size control, homogenization, or analysis.

The mesh count of a sieve defines the number of openings per inch of length. For example, a 40-mesh sieve means there are 40 openings per inch. A higher mesh count means more openings per unit area, resulting in smaller pore sizes and finer sieves. For example, 100 mesh is finer than 40 mesh, 50 mesh is finer than 30 mesh, and 80 mesh is finer than 60 mesh. Sieve pore sizes range from coarse sieves (3 inches) to ultrafine sieves exceeding 500 mesh.

When a mixture is placed on the surface of a Sieve Mesh and an external force (such as vibration, tapping, rotation, or horizontal movement) is applied, particles smaller than the mesh size pass through the mesh under gravity and the external force, achieving "sieving." Particles larger than the mesh size are retained on the mesh surface, becoming "oversize."

During the sieving process, challenges such as particle agglomeration, electrostatic adsorption, and mesh clogging are encountered. Therefore, in standardized particle size analysis, a set of standard sieves is typically used, with sieves of different mesh sizes stacked from top to bottom, from coarse to fine. After the material is vibrated on the top coarse sieve for a period of time, each layer of sieves retains material within a specific particle size range. By weighing the oversize of each layer, the particle size distribution of the entire material can be accurately calculated.

Sieve Mesh offers functions such as grading and screening, filtering impurities, homogenizing particles, and analyzing particle size, depending on the intended use. It provides clean materials or reliable data for subsequent applications.

Grading: This is the core function of a sieve. It separates mixed particles into two or more grades based on size, resulting in a product with uniform particle size. For example, in the construction industry, sand is sieved into coarse, medium, and fine sand to meet the requirements of different concrete mix proportions.

Filtration: In the separation of fluid (liquid or gas) and solid mixtures, a sieve acts as a filter medium, allowing the fluid to pass through while trapping solid particles. For example, it intercepts suspended solids in wastewater treatment or filters oil residue in grain and oil processing.

Testing and Analysis: In laboratories, standard test sieves are one of the authoritative tools for particle size analysis. Through a precise sieving process and standardized operating procedures, the particle size distribution of powdered or granular materials can be determined, which is crucial for product quality control, production process optimization, and scientific research.

The performance and lifespan of a sieve largely depend on sieve mesh manufacturing material. A suitable sieve material possesses sufficient strength, abrasion resistance, corrosion resistance, and fatigue resistance, while avoiding chemical reactions with the material that could contaminate the product. Common materials include:

Metallic Materials:

Stainless Steel: The most commonly used material, especially 304 and 316 stainless steel. They have good corrosion resistance, strength, and durability, making them suitable for most industries, including food, pharmaceuticals, and chemicals.

Brass: Offers some corrosion resistance and is non-sparking, suitable for flammable and explosive environments, but has poor wear resistance.

Low Carbon Steel: Lower cost and high hardness, but not corrosion resistant, usually requiring a protective coating. It is widely used in construction, mining, and other industries where rust prevention requirements are not high.

Non-metallic Materials:

Nylon, Polyester: Lightweight, corrosion resistant, not prone to static electricity, and with stable mesh shape, ideal for applications in the food, pharmaceutical, and chemical industries where metal ion restrictions are strict.

Teflon: Excellent non-stick and chemical inertness, used for screening highly viscous or highly corrosive special materials.

Sieve mesh can screen sand, gravel, cement, and various ores, making it a key piece of equipment for ensuring the quality of building aggregates and improving mineral processing efficiency. It can also classify and filter flour, sugar, salt, starch, milk powder, and pharmaceutical powders. Furthermore, it is used to screen pigments, dyes, resins, fertilizers, and plastic granules; clean and classify seeds; and screen various agricultural by-products. In wastewater treatment and waste sorting, it is used as a filtration and screening device. In laboratories, standard testing sieves are used for precise particle size analysis of various materials, forming the cornerstone of quality control and technological research.

From macroscopic mineral aggregates to microscopic pharmaceutical powders, sieve mesh achieves precise control of material particle size through accurate mesh standards. Its working principle is simple and reliable, and its functions cover three major areas: classification, filtration, and analysis. The diverse material options allow it to adapt to various environments, from daily production to cutting-edge scientific research. By selecting different types of sieves, such as construction sieves, industrial sieves, or laboratory sieves, process efficiency and product quality can be effectively improved.

Soil sieve analysis is a soil particle size determination method based on the principle of mechanical separation...

Juice Powder Ultrasonic Sieve test

The ultrasonic sieve test for juice powder is a fine screening equipment designed for delicate, moisture-absorbing...

Standard Test Method for Particle-Size Analysis of Soils

Standard Test Method for Particle-Size Analysis of Soils (ASTM D422)aims to accurately determine the size distribution of soil particles...

Size sieve for soil primarily involves the sieve frame diameter and sieve aperture size...

Oct 30, 2025

Sieve Mesh is a metal or non-metal device used to separate materials. Its mesh count refers to the nu...

Oct 25, 2025

For Laboratory Sieves Price ranges from $100 to $500 USD, and the price varies depending on the sieve...

Oct 22, 2025

For Laboratory Sieves Suppliers

For Laboratory Sieves Suppliers manufactures sieve frames in 3-inch, 8-inch, and 12-inch diameter siz...

Oct 20, 2025

size sieve for soil is made of stainless steel and can sieve out dust and soil. The fine sieve sizes ...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap