Saturday July-05 2025 18:21:52

The price of electromagnetic sieve vibrators varies greatly due to different models, configurations, and application scenarios, and usually fluctuates between $100 and $1,000. When formulating the ex-factory price of electromagnetic sieve vibrators, the production cost and configuration complexity are considered. The price range is usually simple type (suitable for ordinary test sieves) about $100~$250; standard type (with speed regulation, constant frequency) about $250~$500; high-end type (with ultrasonic sieve, laboratory-level precision control) about $500~$800.

Generally speaking, small electromagnetic sieve vibrators with relatively basic functions are relatively cheap. For example, some small equipment used for simple screening in laboratories may cost as little as more than $100. For some large-scale, high-power, high-precision electromagnetic sieve vibrators, or those with special functions (such as ultrasonic assisted screening), the price will be higher, and some high-end products can even reach about $1,200.

Power size and excitation force design

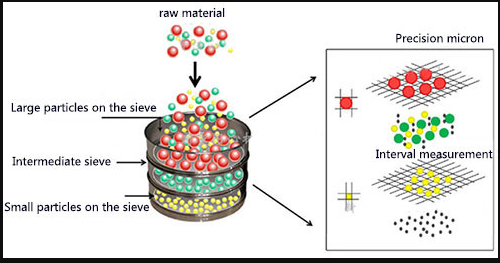

Power directly determines the equipment capacity and adaptation scenarios. The greater the power and the stronger the excitation force, the larger the size of the adapted screen, and the higher the corresponding price. The vibrator suitable for Φ200mm test sieves is much cheaper than the product for Φ400mm or multi-layer sieves.

Low-power vibrators are suitable for small laboratory screens (diameter ≤200mm) and have a simple production process; high-power (above 5kW) industrial-grade products require stronger heat dissipation structure and electromagnetic drive module, and are suitable for ultra-large screens above 3000mm, with higher manufacturing costs. The frequency of ordinary electromagnetic vibrators is 50-60Hz; high-frequency electromagnetic vibrators for precision or high-mesh screening require high frequency stability, and the control cost is also increased

Control system configuration

Products with special functions will be more expensive. For example, products with intelligent adjustment functions that can automatically adjust vibration parameters according to material conditions, or products with ultrasonic assisted screening functions that can effectively prevent fine powder from blocking the screen, will be more expensive than products with ordinary functions. Whether it is equipped with a frequency regulator, timer, digital speed regulator, PLC control interface, etc. is closely related to the price.

The price of ordinary switch type is relatively low, and the price of products with digital control or remote functions is significantly increased. The basic model only contains the start and stop function and is relatively low in price; models equipped with digital regulators (real-time frequency/amplitude adjustment) need to integrate PLC control boards and sensors, which increases costs; intelligent products that support variable frequency speed regulation and automatic timing functions need to add frequency converters and touch screen modules. Some high-end models also have built-in fault diagnosis systems, which further increase prices.

Core component materials

The electromagnetic coil is copper wire (more expensive) or aluminum wire; the core material and the insulation level of the electromagnetic system (such as F class, H class) directly affect the temperature resistance and service life.

Whether it has air cooling/natural heat dissipation design; whether it is equipped with dust cover, anti-corrosion treatment, explosion-proof structure, etc., will increase production costs.

Iron core: The material of silicon steel sheet affects the magnetic permeability. The cost of high-purity cold-rolled silicon steel sheet is 2-3 times that of ordinary materials;

Electromagnetic coil: Compared with aluminum coil, oxygen-free copper coil has strong conductivity and long life;

Insulation and protection: H-class insulation (temperature resistance 180℃), IP65 protection grade products require special coating and sealing process, the cost increases by 25%, and is often used in high temperature and dusty environment, and the price is higher.

Electric is suitable for standard test sieves of different diameters (such as Φ200mm, Φ300mm, Φ400mm) and their supporting experimental vibration screening systems. Parameters include power, vibration frequency, compatible sieve, applicable scope, etc.

|

Model |

compatible sieve diameter |

excitation mode |

voltage (V) |

power (W) |

vibration frequency (Hz) |

amplitude (mm) |

adjustable function |

applicable scope |

|

DZJ-200 |

Φ200mm |

electromagnetic |

220 |

50~60 |

3000/min |

0.1~0.5 |

optional timing/frequency modulation |

powder experiment, medicine, metallurgical analysis |

|

DZJ-300 |

Φ300mm |

electromagnetic |

220 |

80~100 |

3000/min |

0.2~0.8 |

adjustable frequency/timing |

soil screening, ore sieve residue test |

|

EM-3 |

Φ200~300mm |

electromagnetic |

220 |

90 |

50/60Hz |

0.3~0.5 |

No |

Ordinary particle screening, sand and gravel analysis |

|

ZD-60 type |

Φ200mm |

Electromagnetic |

220 |

60 |

3000/min |

0.3~0.5 |

Yes |

Particle detection, chemical sample analysis |

|

ZD-100 type |

Φ300mm |

Electromagnetic |

220/380 |

100 |

3000/min |

0.4~0.6 |

Yes |

Suitable for metal powder screening within 200 mesh |

|

ZD-200 type |

Φ400mm |

Electromagnetic |

220/380 |

200 |

3000/min |

0.5~1.0 |

Support variable frequency adjustment |

Ultrafine powder, high mesh number fine screening |

If it is used in some scenes with low screening requirements, such as simple screening in small workshops, you can choose lower-priced products to control cost expenditure. However, if it is in industries such as food, medicine, and electronic materials that require extremely high screening accuracy, it is more important to pay attention to product quality and performance, and it is necessary to choose higher-priced products such as ultrasonic test sieves. At the same time, product after-sales service is also very important. If you can provide specific application requirements (such as supporting equipment model, screening materials, frequency requirements), we can help recommend suitable models and reasonable quotation ranges.

Jul 05, 2025

What is the price of electromagnetic screen vibrator

The price of electromagnetic sieve vibrators is affected by the model, power, control system, core co...

Jul 05, 2025

Electromagnetic powder ultrasonic test sieve

Electromagnetic powder ultrasonic test sieve mesh covers 20-500 mesh, made of stainless steel, with u...

Jul 04, 2025

Silicon powder ultrasonic test sieve

Silicon powder ultrasonic test sieve is used to analyze the particle size of ultra-fine powders such ...

Jul 03, 2025

Quartz sand ultrasonic slap sieve

Quartz sand ultrasonic slap sieve is a particle size analysis device that combines ultrasonic technol...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap