Tuesday December-02 2025 11:08:27

Size sieve for soil primarily involves the sieve frame diameter and sieve aperture size. Common sieve frame diameters include 200mm, 300mm, and 400mm. Sieve frame sizes such as 75 micron (corresponding to 200 mesh) are primarily used for professional particle size analysis and clay fraction separation. While 40 mesh (pore size approximately 425μm) and 100 mesh (pore size approximately 150μm) are finer, their grading standards often follow the ASTM particle size distribution system. In practice, sieving results must be corrected for soil moisture content. Ultimately, systematic particle size distribution data can be used to simultaneously meet the needs of horticultural compost optimization, seedling soil preparation, and engineering geological testing.

The aperture range of standard soil sieves is usually between 0.075mm and 60mm. Specific apertures include but are not limited to: 0.075mm, 0.25mm, 0.5mm, 1mm, 2mm, 5mm, 10mm, 20mm, 40mm, 60mm, etc. These different apertures are used to separate soil particles of different sizes. For example, a 1mm sieve can be used to screen out dust powder in the soil, while a 3mm sieve can screen out soil particles of 1-3 mm in size.In addition, standard soil sieves usually consist of a set of sieves with multiple sieves of different apertures to facilitate a series of graded screening. For example, a set of standard soil sieves may include 10 sieves of different apertures plus a top cover and a bottom cover.

Commonly used soil sieve sizes include 200 mesh, 100 mesh, 40 mesh, 60 mesh, and 20 mesh, with a maximum sieve size of 800 mesh. Dry or wet sieving methods can be selected based on the soil's moisture content, viscosity, and particle dispersibility. Dry sieving is suitable for loose, dry samples, while wet sieving is more suitable for heavy or easily agglomerated soils.

200 mesh (0.075mm aperture): used to separate extremely fine soil particles, such as clay particles. In soil texture analysis, it can help distinguish the amount of clay in the soil. For example, when studying the water retention and nutrient adsorption capacity of the soil, the clay content is an important indicator because clay particles have a larger specific surface area and can absorb more water and nutrients.

100 mesh (0.15mm aperture): can separate particles slightly larger than 200 mesh, usually used for preliminary screening of fine particles in soil. In some soil sample preparation processes, a 100 mesh sieve is first used to screen to remove larger impurities, and then a finer sieve is used for further separation.

60 mesh (0.25mm aperture): used to separate fine sand and silt in soil. In soil texture classification, the distinction between silt and fine sand is important for judging the air permeability and water permeability of soil. For example, soil with a high silt content has a water permeability between clay and sand.

40 mesh (0.425mm aperture): can separate larger soil particles, such as coarse sand. In the construction industry, for some projects that require sand as filling material, a 40 mesh sieve can be used to screen out the appropriate sand particle size to ensure the performance of the filling material.

20 mesh (0.85mm aperture): used to separate gravel and coarse sand. In water conservancy projects, for the analysis of riverbed soil, a 20-mesh sieve can help determine the gravel content, which is important for evaluating the stability of the riverbed and the scouring effect of water flow.

10 mesh (2mm aperture): used to separate larger gravel and small stones. In the agricultural field, for some operations that require land leveling, a 10-mesh sieve can be used to screen out larger stones so that they can be removed to ensure the farming conditions of the land.

|

Net |

Aperture (mm) |

Net |

Aperture (mm) |

Net |

Aperture (mm) |

|

2 mesh |

12.5 |

45 mesh |

0.4 |

220 mesh |

0.065 |

|

3 Mesh |

8 |

50mesh |

0.355 |

240mesh |

0.063 |

|

4 mesh |

6 |

55 mesh |

0.315 |

250 mesh |

0.061 |

|

5 mesh |

6 |

60 mesh |

0.28 |

280 mesh |

0.055 |

|

6 mesh |

4 |

65 mesh |

0.25 |

300 mesh |

0.050 |

|

8 mesh |

3 |

70 mesh |

0.224 |

320 mesh |

0.045 |

|

10 mesh |

2 |

75 mesh |

0.2 |

325 mesh |

0.043 |

|

12 mesh |

1.6 |

80 mesh |

0.18 |

340 mesh |

0.041 |

|

14 mesh |

1.43 |

90 mesh |

0.16 |

360 Head |

0.040 |

|

16 mesh |

1.25 |

100 mesh |

0.154 |

400 mesh |

0.0385 |

|

18 mesh |

1 |

110 mesh |

0.15 |

500 mesh |

0.0308 |

|

20 mesh |

0.9 |

120 mesh |

0.125 |

600 mesh |

0.026 |

|

24 mesh |

0.8 |

130 mesh |

0.112 |

800 mesh |

0.022 |

|

26 mesh |

0.71 |

140 mesh |

0.105 |

900 mesh |

0.020 |

|

28 mesh |

0.68 |

150 mesh |

0.100 |

10 00 mesh |

0.015 |

|

30 mesh |

0.6 |

160 mesh |

0.096 |

1800 mesh |

0.010 |

|

32 mesh |

0.58 |

180 mesh |

0.09 |

2000 mesh |

0.008 |

|

35 mesh |

0.50 |

190 mesh |

0.08 |

2300 mesh |

0.005 |

|

40 mesh |

0.45 |

200 mesh |

0.074 |

2800 mesh |

0.003 |

| Testing Sieve Specification | ||

| Sieve Material | Brass, AISI304/316/316L,galvanized,etc. | |

| Technology | Woven | |

| Standard | ASTM E11-09 ISO3310-1 | |

| Sieve Diameter | 3" 6" 8" 10" 12" 200mm 300mm | |

| Frame | Material | Brass , stainless steel ,etc. |

| Height (full) | 1-3/4'' -- 2-5/8'' | |

| Aperture shape | Square | |

| Mesh opening / Aperture | 5--500mesh 10--200μm | |

| ASTM E11 | ISO 565/3310-1 | |

|---|---|---|

| Standard | Alternate | Size |

| 100.0mm | 4in | - |

| 90.0mm | 3 1/2in | - |

| 75.0mm | 3in | - |

| 63.0mm | 2 1/2in | 63.0mm |

| - | - | 56.0mm |

| 53.0mm | 2.12in | 53.0mm |

| 50.0mm | 2in | 50.0mm |

| 45.0mm | 1 3/4in | 45.0mm |

| - | - | 40.0mm |

| 37.5mm | 1 1/2in | 37.5mm |

| - | - | 35.5mm |

| 31.5mm | 1 1/4in | 31.5mm |

| - | - | 28.0mm |

| 26.5mm | 1.06in | 26.5mm |

| 25.0mm | 1in | 25.0mm |

| 22.4mm | 7/8in | 22.4mm |

| - | - | 20.0mm |

| 19.0mm | 3/4in | 19.0mm |

| 18.0mm | - | 18.0mm |

| 16.0mm | 5/8in | 16.0mm |

| - | - | 14.0mm |

| 13.2mm | 0.530in | 13.2mm |

| 12.5mm | 1/2in | 12.5mm |

| 11.2mm | 7/16in | 11.2mm |

| - | - | 10.0mm |

| 9.5mm | 3/8in | 9.5mm |

| - | - | 9.0mm |

| 8.0mm | 5/16in | 8.0mm |

| - | - | 7.1mm |

| 6.7mm | 0.265in | 6.7mm |

| 6.3mm | 1/4in | 6.3mm |

| 5.6mm | No. 3 1/2 | 5.6mm |

| - | - | 5.0mm |

| 4.75mm | No.4 | 4.75mm |

| - | - | 4.50mm |

| 4.00mm | No.5 | 4.00mm |

| 3.55mm | - | 3.55mm |

| 3.35mm | No.6 | 3.35mm |

| - | 1/8in* | - |

| 3.15mm | - | 3.15mm |

| 2.80mm | No.7 | 2.80mm |

| - | - | 2.50mm |

| 2.36mm | No.8 | 2.36mm |

| 2.00mm | No.10 | 2.00mm |

| - | - | 1.80mm |

| 1.70mm | No.12 | 1.70mm |

| - | - | 1.60mm |

| 1.40mm | No.14 | 1.40mm |

| - | - | 1.25mm |

| 1.18mm | No.16 | 1.18mm |

| - | - | 1.12mm |

| 1.00mm | No.18 | 1.00mm |

| - | - | 900µm |

| 850μm | No.20 | 850µm |

| - | - | 800µm |

| 710μm | No.25 | 710µm |

| - | - | 630µm |

| 600μm | No.30 | 600µm |

| - | - | 560µm |

| 500μm | No.35 | 500µm |

| - | - | 450µm |

| 425μm | No.40 | 425µm |

| - | - | 400µm |

| 355μm | No.45 | 355µm |

| - | - | 315µm |

| 300μm | No.50 | 300µm |

| - | - | 280µm |

| 250μm | No.60 | 250µm |

| - | - | 224µm |

| 212μm | No.70 | 212µm |

| - | - | 200µm |

| 180μm | No.80 | 180µm |

| - | - | 160µm |

| 150μm | No.100 | 150µm |

| - | - | 140µm |

| 125μm | No.120 | 125µm |

| - | - | 112µm |

| 106μm | No.140 | 106µm |

| - | - | 100µm |

| 90μm | No.170 | 90µm |

| - | - | 80µm |

| 75μm | No.200 | 75µm |

| - | - | 71µm |

| 63μm | No.230 | 63µm |

| - | - | 56µm |

| 53μm | No.270 | 53µm |

| - | - | 50µm |

| 45μm | No.325 | 45µm |

| - | - | 40µm |

| 38μm | No.400 | 38µm |

| - | - | 36µm |

| 32µm | No.450 | 32µm |

| 25µm | No.500 | 25µm |

| 20µm | No.635 | 20µm |

The mesh size of a soil sieve depends on its specific application. Different sieve mesh sizes are used for horticulture and composting, promoting seed germination, and professional testing. The following are specific guidelines for selecting sieve sizes.

For general gardening and composting: A 10mm-20mm (approximately 2-0.8 mesh) sieve can be used as a "coarse screen," primarily for removing fist-sized clods, large rocks, branches, and partially decomposed compost. A 5mm-10mm (approximately 4-2 mesh) sieve is the most commonly used and practical, producing fine, uniform soil without noticeable rocks. This makes it ideal for general-purpose soil in vegetable gardens, flower beds, and potted plants, removing impurities while preserving good soil structure and fertility.

For high-quality soil and seed germination: A 3mm-5mm (approximately 6-4 mesh) sieve can produce high-quality potting soil, suitable for growing plants with high soil requirements (such as succulents and orchids, which require mixing with other media), or as a topsoil for sowing. A 2mm-3mm (approximately 10-6 mesh) sieve is the ideal size for preparing soil specifically for seed germination and seedling cultivation. The resulting soil is as fine as a powder, making it ideal for filling seed trays and seed boxes.

For professional testing: A complete set of standard sieves can be stacked together, in descending order of aperture, for vibratory screening. Common standard sieve series (based on USDA standards): 2mm (10 mesh) separates coarse sand and larger particles; 0.5mm (35 mesh) separates medium sand; 0.25mm (60 mesh) separates fine sand; 0.075mm (200 mesh) separates fine particles.

Improper use of a soil sieve can clog the sieve holes, leading to inaccurate sieving results. The following are precautions for handling the sieve before, during, and after use to help ensure more organized operation and more accurate results.

Preparation before screening: Before screening the soil, the soil needs to be air-dried to remove the moisture. Because wet soil particles tend to stick together, affecting the accuracy of screening. At the same time, make sure that there are no large impurities in the soil, such as plant roots, plastic fragments, etc., which may block the sieve holes and interfere with the screening process.

Sieving operation: Place the soil sample on the sieve and gently vibrate the sieve to allow the soil particles to pass through the sieve holes. The amplitude of vibration should not be too large to avoid damaging the screen or splashing soil particles. For finer sieves, such as 200 mesh sieves, it may take a long time to vibrate to allow most of the fine particles to pass through the sieve holes. During the screening process, pay attention to the condition of the screen. If the sieve holes are found to be blocked, they should be cleaned in time.

Post-screening treatment: After the screening is completed, collect the soil particles on and under the sieve separately. For the soil particles on the sieve, further analysis or treatment can be carried out as needed. For the soil particles under the sieve, if further separation is required, a finer sieve can be used to continue screening. At the same time, the sieved soil particles should be marked and recorded for subsequent research or application.

Size sieve for soil, also commonly known as a soil particle size analysis sieve, is a tool used to perform particle size analysis on soil samples. Its core application is to classify and evaluate soils based on particle size. Specifically, its applications include soil texture classification. Sieving soil through a series of sieves with varying apertures can separate particles of varying sizes, such as sand, silt, and clay. Determining the percentage of particles of different sizes allows for accurate soil texture classification according to international or national standards. In civil engineering and geological engineering, soil particle distribution is a key parameter for predicting its physical and mechanical behavior. Sieve analysis can assess soil gradation and determine whether the particle size distribution is uniform. For example, "well-graded" soil typically has a high density and is suitable for foundation material, while "poorly graded" soil may contain more porosity and require treatment. Soil sieving is also widely used in environmental science. Sieving can separate soil particles of varying sizes, allowing analysis of heavy metals, organic pollutants, and other contaminants in each particle size fraction. Because fine particles (clay) generally have stronger adsorption capacity, this fractionation analysis helps more accurately assess the distribution and migration risk of pollutants. In soil remediation projects, it is sometimes necessary to sort contaminated soil by particle size to remove heavily contaminated fine particles, thereby reducing treatment costs. Agricultural researchers and farmers also use soil sieving techniques. Understanding soil texture helps select crops suitable for specific soil types and develop appropriate tillage and irrigation plans. Soil texture affects fertilizer retention. Sieving analysis allows for more informed application of fertilizers and soil amendments to improve soil fertility and promote crop growth. In short, size sieve for soil is a fundamental tool for obtaining soil particle distribution data. This data is crucial for understanding soil physical, chemical, and engineering properties, and is widely used in research, engineering, the environment, and agriculture.

For #8 sieve,

Sieve weight = 491.8 gm

Sieve + soil weight = 504 gm

Weight of soil retained = (504 – 491.8) = 12.2 gm

Percent retained= $2.2/300 × 100 = 4.07%

Cumulative percent retained= 0 + 4.07 = 4.07%

Percent finer= 100 – 4.07= 95.93%

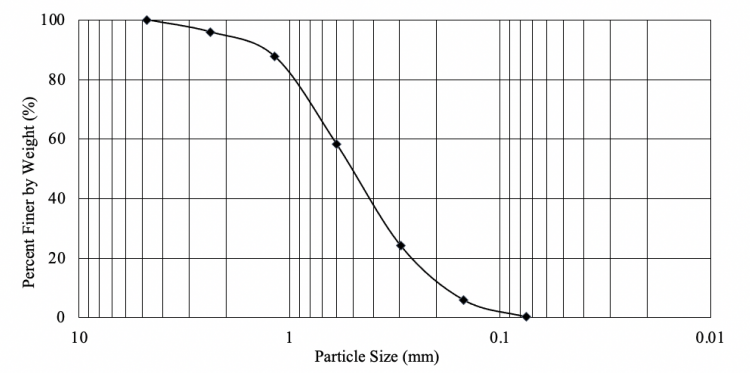

The grain-size distribution of the soil sample can be obtained by plotting the percent finer with the corresponding sieve on semi-log graph paper, as shown below. An example of the grain-size distribution curve is shown in Figure 3.7.

he values of D10, D30, and D60, which are the diameters that correspond to the percentfiner of 10%, 30%, and 60%, respectively can be determined from the grain-size distributioncurve. The values of the uniformity coefficient Cu and the coefficient of gradation Cc can be calculated using the following equations:

The values of Cu and Cc are used to classify whether the soil is well-graded or not. Sand isconsidered well-graded, if Cu is greater than 6 and Cc is between 1 and 3. For gravel to be considered as well-graded, Cu should be greater than 4 and Cc should be between 1 and 3.

From Figure 3.5,

D10= 0.18, D30= 0.35, and D60= 0.61

Uniformity coefficent, Cu=D60/D10=0.61/0.18=3.39

Coefficent of gradation, Cc= (D230)/(D60×D10)=(0.35)2/(0.61×0.18) =1.12

In short, the size of the soil sieve should be determined according to the specific purpose and requirements of the soil analysis. The correct use of the soil sieve can effectively help us understand the physical properties of the soil and provide important data support for the research and application of the soil.

What is the wet sieving process?

Wet sieving process is a sieving process assisted by a liquid (usually water or a solution containing a dispersant) to more effectively...

Fines content tester can be defined as an instrument used to quantitatively determine the content of fines powder components of a specific fineness...

Micro silica powder particle size analysis test sieve

Micro silica powder, also known as silica fume, is an ultrafine active silica material with a very small particle size, usually between 0.1-0.3 microns, which...

Agricultural gruesos Test sieves

Agricultural gruesos test sieves are experimental equipment used for particle size analysis, grading and testing of agricultural soil, gruesos...

Stainless steel frame and woven cloth

The test sieve is a laboratory equipment used for particle size analysis. Its core components usually include a stainless steel frame and woven cloth (also called a sieve)...

Dec 02, 2025

size sieve for soil is made of stainless steel and can sieve out dust and soil. The fine sieve sizes ...

Nov 29, 2025

material particle size test sieve

material particle size test sieve helps generate a reliable material particle size distribution throu...

Nov 27, 2025

Laboratory Sieve for Calcining Clay

Laboratory Sieve for Calcining Clay has a sieve particle size ranging from 63 μm to 250 μm and can ...

Nov 26, 2025

Lab test sieves with materials include brass, stainless steel, or brass frames with stainless steel m...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap