Monday April-21 2025 15:41:39

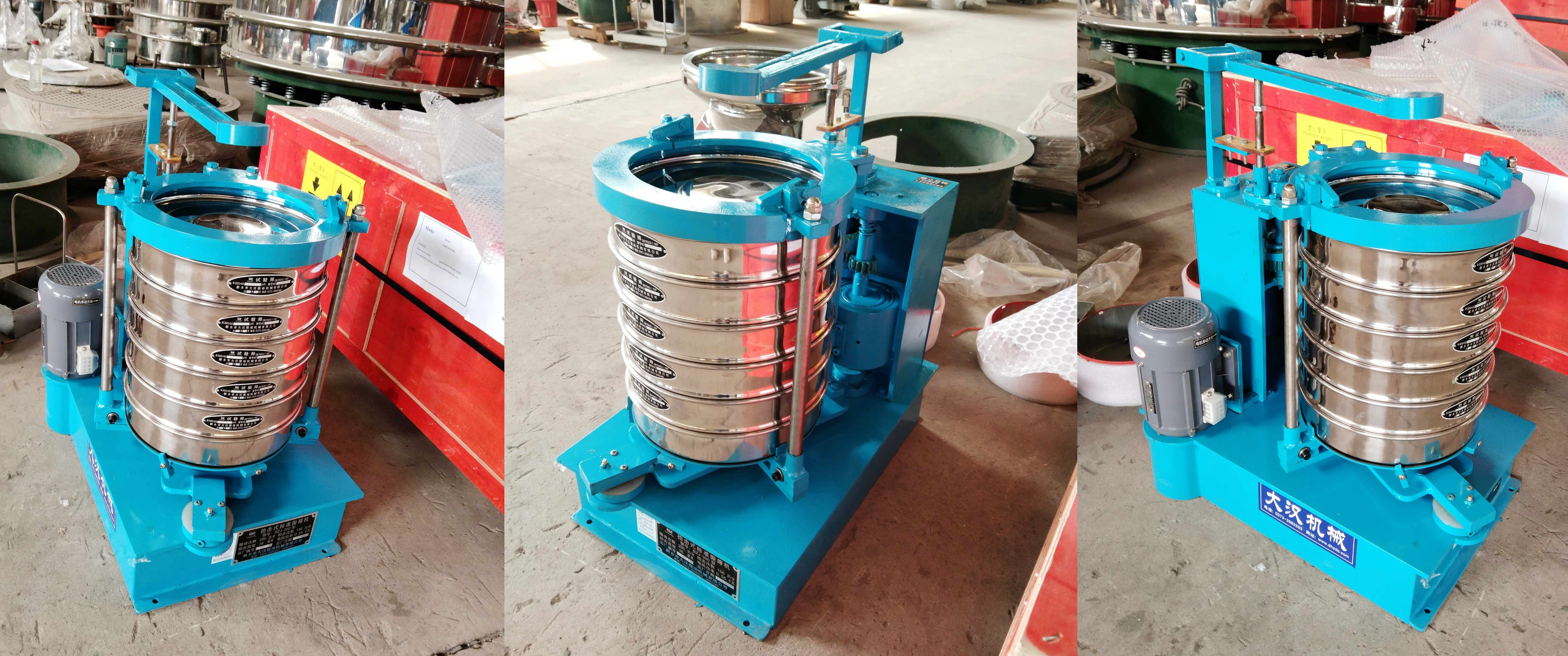

Yeast powder is a commonly used pharmaceutical excipient, widely used in fermentation preparations, nutritional supplements or as a component of microbial culture medium. Yeast powder has unique physical and chemical properties (such as hygroscopicity, stickiness, fine particle size, etc.), and has high requirements for screening equipment and mesh number. The yeast powder slapping sieve is a screening equipment designed for screening light and easy-to-clump powders such as yeast powder. By using the composite drive mode of slapping and vibration, the yeast powder is evenly screened to meet the requirements of particle size control, quality inspection or ingredient accuracy.

The motor drives the gear to change speed through the synchronous belt to make the main shaft rotate.

The main shaft drives the eccentric wheel, so that the slide plate drives the screen frame to shake left and right, and at the same time, the top rod gear hits the top rod through the cam, so that the hammer hits the screen frame up and down.

The material reciprocates and vibrates up and down on the screen, and particles smaller than the screen aperture pass through the screen to achieve particle size classification.

Structural design that resists moisture absorption and agglomeration: The sieve body is made of stainless steel (such as 316L), and the top is equipped with a frequency-adjustable slapping rod. By periodically slapping the screen cover (frequency 50~200 times/minute), a vertical impact force is generated to break the yeast powder agglomerates (especially wet materials with a moisture content of >8%).

Low-damage gentle screening movement: Combined movement is adopted, and the screen box performs horizontal circular motion (amplitude 2~8mm, speed 100~300r/min), so that the material is evenly dispersed on the screen surface, avoiding the violent shaking of the traditional slapping sieve that causes yeast cell breakage.

Precise control ability of particle size classification: The yeast powder slap slapping sieve adopts stainless steel woven mesh or punching plate, with surface polishing (roughness Ra≤0.8μm) or Teflon (PTFE) coating to reduce material adhesion and improve screening efficiency (such as the pass rate is 20% higher than that of ordinary sieves).

Laboratory and small batch applicability: The equipment is small in size and easy to operate, suitable for laboratory or small-scale production. The yeast powder slapping sieve meets the needs of R&D or quality control (such as 200-325 mesh particle size analysis).

The mesh number (mesh) indicates the aperture of the sieve. The mesh number selection of yeast powder depends on its application and particle size distribution:

Common mesh number range:

Coarse sieve (removal of impurities): 100-150 mesh (100-150μm), used to remove agglomerates or larger foreign matter, suitable for fermentation preparations or granules.

Fine sieve (uniform particle size): 200-325 mesh (45-75μm), used to prepare highly uniform yeast powder, suitable for culture medium or tablet/capsule filling.

Ultrafine sieve (special purpose): 325-400 mesh (38-45μm), used for ultrafine yeast powder (such as nano-grade fermentation excipients), commonly used in high-end nutritional supplements.

Multi-stage screening requirements: Due to the wide particle size distribution of yeast powder (such as 10-150μm), multiple layers of sieves (such as 100 mesh + 200 mesh + 325 mesh) are often required to achieve classification.

Raw material pretreatment stage: Before yeast powder enters the production process as an auxiliary material, it needs to be pre-screened to ensure uniform particle size and remove impurities or agglomerates. The yeast powder slapping sieve can screen out particle sizes that meet process requirements (such as 100-325 mesh, 45-150μm) to ensure the consistency of yeast powder in subsequent mixing, fermentation or formulation.

Laboratory R&D and formula optimization stage: Yeast powder is often used in the test of fermentation preparations or nutritional supplements, and small batches of precise screening are required to determine the optimal particle size or verify process parameters. By ensuring that the yeast powder particle size meets the test requirements (such as 200-325 mesh), the repeatability and reliability of the experimental results are improved.

Preparation of culture medium in fermentation preparation production: Yeast powder is often used as a nitrogen source or nutrient component of microbial culture medium. It needs to be sieved before the culture medium is prepared to ensure uniformity and purity. By screening out consistent particle sizes (such as 150-200 mesh, 75-100μm), the culture medium components are ensured to be mixed evenly and the growth of microorganisms is promoted.

Excipient preparation in tablet or capsule production: Yeast powder is used as an active excipient in tablets or capsules of some nutritional supplements and needs to be sieved to meet tableting or filling requirements. Screen out the particle size suitable for tableting (200-325 mesh, 45-75μm) or capsule filling (150-200 mesh, 75-100μm) to improve mixing and fluidity.

Yeast powder slapping sieve is a professional sieving equipment designed for the viscosity, hygroscopicity, poor fluidity and static electricity of yeast powder (particle size 10-150μm, mesh size 100-400 mesh). The slap screen is particularly suitable for screening yeast powder in laboratories or small-scale production to ensure uniform particle size, purity and no impurities. If you need a mesh size or equipment configuration recommended for a specific yeast powder (such as a certain brand or use), you can provide us with more details (such as particle size distribution, output or production environment), and we will provide you with specific information and quotes.

Phosphate Test Sieve is an experimental tool used to screen different particle sizes in phosphate samples and detect the phosphate...

Vitamin powder slapping screen

Vitamin powder slapping screen is a device used to screen vitamin powder. It screens materials through mechanical vibration and slapping...

Stainless steel sieve shaker model features

Stainless steel sieve shaker is an important tool for particle size analysis. Its model features are mainly reflected...

What is the wet sieving process?

Wet sieving process is a sieving process assisted by a liquid (usually water or a solution containing a dispersant) to more effectively...

Brass Sieve Shaker manufacturer

One of the manufacturers of brass sieve shakers is Xinxiang Dahan Vibration Machinery Co., Ltd. (referred to as "Dahan Machinery"). Our company...

Fines content tester can be defined as an instrument used to quantitatively determine the content of fines powder components of a specific fineness...

Apr 21, 2025

A laboratory or small batch screening equipment designed for fine, sticky or hygroscopic pharmaceutic...

Apr 17, 2025

Fines content tester is a device used to quickly and quantitatively analyze the fines powder content ...

Apr 15, 2025

Nylon sieve shaker mesh is a mesh filter material woven from nylon material (usually nylon 6, nylon 6...

Apr 14, 2025

Stainless steel frame and woven cloth

The stainless steel frame provides a sturdy support structure, while the precision-woven stainless st...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap