![[field:title/]](/uploads/allimg/250522/2-2505221550360-L.png)

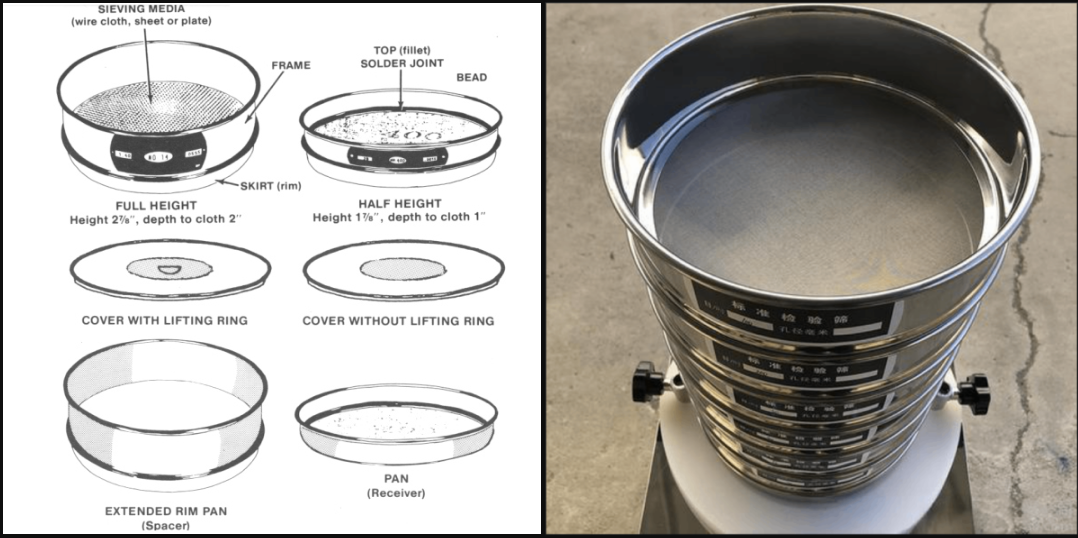

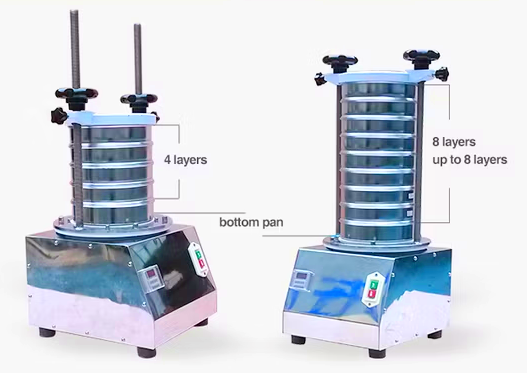

Glass bead test sieve is a special testing tool designed based on the characteristics of glass beads, such as high hardness, brittle texture, small particle size and strict distribution requirements. It is used to accurately measure the particle size distribution and particle size uniformity of glass beads. It is usually composed of 7 layers of sieves with different apertures, from top to bottom, 2.00mm, 1.18mm, 0.85mm, 0.60mm, 0.30mm, 0.18mm and chassis, and the glass beads are naturally layered according to the particle size through vibration.

Diameter: 75mm/100mm/200mm/300mm

Sieving fine to 0.025-3mm

Timed automatic shutdown to ensure test repeatability

A granular material can be accurately separated into 2-7 particle segments at the same time

Glass bead test sieve, also known as test sieve or analysis sieve, is a device specially used to accurately measure the particle size distribution of glass beads. Considering the roundness, brittleness, fluidity and high requirements for particle size uniformity of glass beads, the test screen is usually composed of a series of standard precision screens, the apertures of which are arranged from coarse to fine, generally 2 to 8 layers, and used in conjunction with an electric vibrating screen.

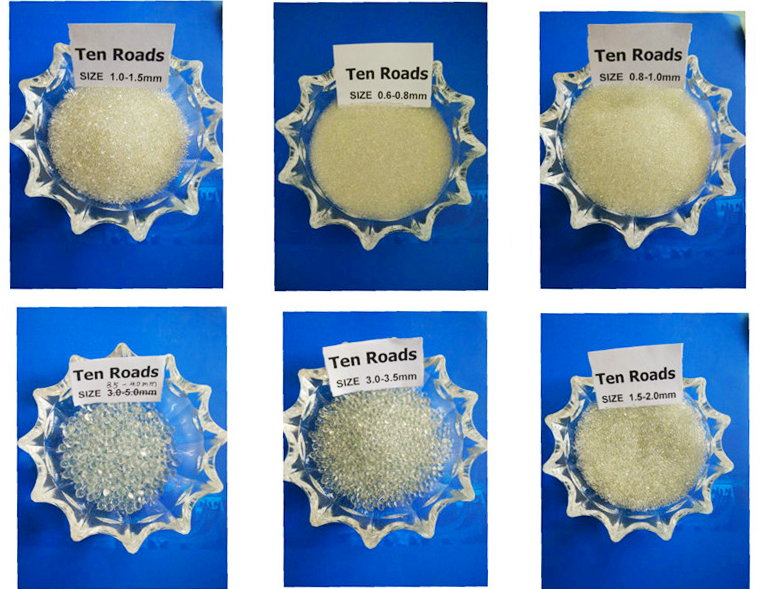

The glass beads are separated step by step in each layer of the screen through vibration, and the particle size distribution is finally analyzed based on the mass of the material on and under the screen. The screen aperture range usually covers from 100 microns to 2 mm, which can meet the detection needs of different particle size specifications such as reflective beads for road markings and glass beads for shot peening. This equipment is suitable for particle size detection and quality control of small and medium batch samples in scientific research laboratories, quality inspection departments and production enterprises, and is an important tool to ensure the consistency and application performance of glass bead products.

|

Project |

Glass bead test sieve (experimental test) |

Glass bead screening machine (industrial screening) |

|

Image |

|

|

|

Main function |

Laboratory-level precision test and analysis of glass bead particle size |

Industrial continuous grading and screening of large quantities of glass beads |

|

Applicable scenarios |

Laboratories, quality inspection departments, R&D units |

Factory production lines, material pretreatment, product grading links |

|

Screening speed |

Generally 5~10 minutes/batch (sample volume is about 100g) |

500~5000kg per hour, depending on the machine model |

|

Screening capacity |

The sample volume of each batch is about 50~300 grams |

Strong industrial continuous processing capacity, suitable for large-scale material processing |

|

Screening accuracy |

Extremely high, the error is controlled within ±2%, in line with the test standards |

Medium and high level, the error is usually around ±5% |

|

Screening efficiency |

Relatively low, dependent on vibration screening time and manual participation |

High Efficiency, can run continuously for a long time, automatic screening and discharging |

|

Number of screening layers |

usually 2~8 layers of standard test sieves |

mostly 1~5 layers of industrial sieves, customized according to grading requirements |

|

Sieve hole specifications |

strictly follow the standard aperture (such as 150μm, 300μm, etc.) |

customizable aperture, adapted to different particle size grading requirements |

|

Representative equipment |

Φ200mm stainless steel test sieve + electric standard vibrating screen |

three-dimensional vibrating screen, linear vibrating screen, drum screen, etc. |

|

Whether to operate continuously |

no, a single operation is a batch test |

yes, can run continuously for a long time |

|

Result processing method |

manually weigh the mass of each layer of the sieve, calculate the particle size distribution |

automatic grading and screening, collect materials of different particle sizes through the discharge port |

Glass bead detection sieve focuses on particle size detection, emphasizes high precision and standardization, suitable for small sample analysis, glass bead screening machine tends to be high-efficiency, large-scale screening operation, suitable for grading processing in the production process

The working principle of glass bead test sieve is based on physical screening and particle size classification technology. Its core is to achieve accurate stratification of glass beads according to particle size through vibration or shaking of multiple layers of standard aperture sieves.

It consists of a group of vertically stacked sieves, and the sieve apertures are arranged in order from large to small (such as 2.00mm, 1.18mm, 0.85mm to 0.18mm).

Pour the glass bead sample to be tested into the top sieve, and through mechanical vibration or manual shaking of the equipment, the spherical structure of the glass beads and the action of gravity make the particles roll and jump on the sieve surface. Glass beads with larger particle sizes are intercepted by the upper sieve, and smaller particles fall into the lower layer through the sieve holes, and finally stratification by particle size is achieved.

Glass bead test sieve is a special test equipment for measuring the particle size distribution of glass beads. It consists of a set of standard sieves with different apertures (stacked from large to small according to particle size), usually including sieve frame, sieve, bottom plate and cover. Through mechanical vibration or manual shaking, the glass beads are layered according to particle size to analyze their particle size distribution.

Screen: woven from metal wire (such as stainless steel), the aperture size strictly follows the standard, and common specifications are 45μm, 75μm, 106μm, 150μm, 212μm, etc.

Screen frame: generally a circular metal frame (such as aluminum alloy or stainless steel), fixed sieve and easy to operate, the diameter is commonly 200mm or 300mm.

Matching components: including base, top cover, vibrating screen machine (used to assist screening and improve efficiency), etc.

|

Mesh number |

Aperture (mm) |

Mesh number |

Aperture (mm) |

Mesh number |

Aperture (mm) |

|

2 mesh |

12.5 |

45 mesh |

0.4 |

220 mesh |

0.065 |

|

3 mesh |

8 |

50 mesh |

0.355 |

240 mesh |

0.063 |

|

4 mesh |

6 |

55 mesh |

0.315 |

250 mesh |

0.061 |

|

5 mesh |

6 |

60 mesh |

0.28 |

280 mesh |

0.055 |

|

6 mesh |

4 |

65 mesh |

0.25 |

30 0 mesh |

0.050 |

|

8 mesh |

3 |

70 mesh |

0.224 |

320 mesh |

0.045 |

|

10 mesh |

2 |

75 mesh |

0.2 |

325 mesh |

0.043 |

|

12 mesh |

1.6 |

80 mesh |

0.18 |

340 mesh |

0.041 |

|

14 mesh |

1.43 |

90 mesh |

0.16 |

360 mesh |

0.040 |

|

16 mesh |

1.25 |

100 mesh |

0.154 |

400 mesh |

0.0385 |

|

18 mesh |

1 |

110 mesh |

0.15 |

5 00 mesh |

0.0308 |

|

20 mesh |

0.9 |

120 mesh |

0.125 |

600 mesh |

0.026 |

|

24 mesh |

0.8 |

130 mesh |

0.112 |

800 mesh |

0.022 |

|

26 mesh |

0.71 |

140 mesh |

0.105 |

900 mesh |

0.020 |

|

28 mesh |

0.68 |

150 mesh |

0.100 |

1000 mesh |

0.015 |

|

30 mesh |

0.6 |

160 mesh |

0.096 |

1800 mesh |

0.010 |

|

3 2 mesh |

0.58 |

180 mesh |

0.09 |

2000 mesh |

0.008 |

|

35 mesh |

0.50 |

190 mesh |

0.08 |

2300 mesh |

0.005 |

|

40 mesh |

0.45 |

200 mesh |

0.074 |

2800 mesh |

0.003 |

Glass bead test sieve has two types of mesh: wire woven mesh with mesh size GB6003.1-1997 and punched plate mesh with mesh size GB6003.2-1997.

Basic mesh size w\Basic mesh size w\Basic mesh size w\Wire diameter d\Screening area percentage A0%\Basic mesh size\Basic mesh size\Basic mesh size\Wire diameter d\Screening area percentage A0%

|

Basic mesh size |

Wire diameterd |

Screening area percentage A0% |

Basic mesh size |

Wire diameter d |

Screening area percentage A0% |

||||

|

Main size |

Supplementary size |

Main size |

Supplementary size |

Supplementary size |

|||||

|

R20/3 |

R/20 |

R40/3 |

R20/3 |

R/20 |

R40/3 |

||||

|

|

900 |

|

500 |

41 |

180 |

180 |

180 |

125 |

35 |

|

|

|

850 |

500 |

40 |

|

160 |

|

112 |

35 |

|

|

800 |

|

450 |

41 |

|

|

150 |

100 |

36 |

|

710 |

710 |

710 |

450 |

37 |

|

140 |

|

100 |

34 |

|

|

630 |

|

400 |

37 |

125 |

125 |

125 |

90 |

34 |

|

|

|

600 |

400 |

36 |

|

112 |

|

80 |

34 |

|

|

560 |

|

355 |

37 |

|

|

106 |

71 |

33 |

|

500 |

500 |

500 |

315 |

38 |

|

100 |

|

71 |

34 |

|

|

450 |

|

280 |

38 |

90 |

90 |

90 |

63 |

35 |

|

|

|

425 |

280 |

36 |

80 |

|

|

56 |

35 |

|

|

400 |

|

250 |

38 |

|

|

75 |

50 |

36 |

|

355 |

355 |

355 |

224 |

38 |

|

|

75 |

50 |

34 |

|

|

315 |

|

200 |

37 |

63 |

63 |

63 |

45 |

34 |

|

|

|

300 |

200 |

36 |

|

56 |

|

40 |

35 |

|

|

280 |

|

180 |

37 |

|

|

53 |

36 |

35 |

|

250 |

250 |

250 |

160 |

37 |

|

50 |

|

36 |

34 |

|

|

224 |

|

160 |

34 |

45 |

45 |

45 |

32 |

35 |

|

|

|

212 |

140 |

36 |

|

40 |

|

32 |

31 |

|

|

200 |

|

140 |

35 |

|

|

38 |

30 |

31 |

Glass bead test sieve has a wide range of applications, closely surrounding various application scenarios of glass beads. In the field of transportation, it is used to detect glass beads for road markings to ensure that their particle size meets the standards, ensure good reflective performance, and improve night driving safety; in industrial grinding, it detects the particle size of abrasive glass beads to ensure grinding efficiency and accuracy. When producing optical instruments, the particle size of optical glass beads is tested to ensure the stability of their optical properties such as refraction and focusing. In the cosmetics industry, glass beads used to make fillers are tested to ensure that their particle size is uniform to avoid irritation to the skin. In addition, the fields of architectural coatings and 3D printing materials also rely on glass bead detection screens to control the particle size of glass beads, ensure the quality of finished products, and meet the stringent requirements of different industries for the particle size of glass beads.

Test Analysis Sieve is a sieve for separating mixtures. It mainly makes the mixture of particles of different...

Sieve Analysis Test is mainly used for grading the particle size composition of various powder materials,...

Soil Test Sieve can be used for soil grading, screening, analysis, testing, filtering various soils, widely used...

Standard Sieves standard sieve is a tool for particle size classification and particle size detection of material...

stainless steel pollen laboratory test sieve

Stainless steel pollen laboratory test sieve is a precision tool for pollen separation, classification and purity testing. It is an ideal choice because of its stable material, corr...

The low-priced coffee test sieve is a key tool for evaluating the particle size distribution of coffee powder, which directly affects the extraction and flavor of coffee. It is main...

Laboratory test sieve used for fertilizer particle screening

Laboratory test sieve is a precision screening equipment widely used for detecting the particle size distribution of fertilizer particles, ensuring that the finished product meets q...

Lab Sieve Analysis Equipment for Calcium Carbonate

lab sieve equipment for calcium carbonate is a key instrument for accurately analyzing and grading the particle size distribution of different types of calcium carbonate (such as he...

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap