Friday November-21 2025 15:10:15

Material screening test sieves are tools used in laboratories and industry for particle size analysis of particulate materials. The sieve mesh sizes range from coarse sieves (125mm, 150mm) to fine analytical sieves (20µm, 38µm), conforming to standards such as ASTM E11 and ISO 3310-1. Sieves are made of materials including stainless steel, nickel, electroformed mesh, and brass, and frame diameters are typically 200mm, 300mm, and 400mm. Frame heights are available in full-height and half-height versions; full-height frames offer greater sample capacity, while half-height frames facilitate stacking and multi-stage sieving, saving space. The equipment conforms to international standards including ASTM E11 (USA), ISO 3310-1 (Europe), and GB/T 6003.1 (China), ensuring sieve manufacturing precision and comparability of test results globally.

A material screening test sieve utilizes mechanical vibration, impact, or gravity to cause relative movement of materials on the sieve surface. Particles pass through sieve layers with different apertures according to their size, achieving grading and particle size distribution measurement. The sieving process typically includes: sample preparation, stacking sieves from largest to smallest aperture (top to bottom), setting the vibrating sieve parameters, sieving, and weighing the material remaining on the sieve. The sample input should be determined according to industry standards or the equipment manual, generally 1/4 to 1/2 of the sieve frame volume to avoid clogging and affecting sieving efficiency. The sieving time is typically 5 to 20 minutes, adjusted according to the material characteristics; lighter and more easily agglomerated powders require longer times.

| Description. | Overall Dia. | Hole Dia. | Material |

| Sample Preparation Sieve | 700x500x150mm | 150-3mm | Stainless Steel / Wood Frame |

| Sample Preparation Sieve | Φ450x100mm | 25-1mm | Stainless Steel |

| Sample Preparation Sieve | Φ300x60mm | 6-0.2mm | Stainless Steel |

| Sample Preparation Sieve | Φ200x50mm | 6-0.045mm | Double Layer Stainless Steel |

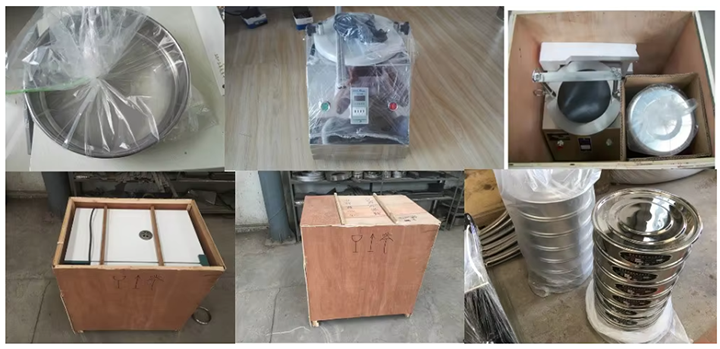

A material screening test sieve kit typically includes multiple layers of test sieves, sieve covers, and a base. Vibrating sieve machines are available in electromagnetic, mechanical, and ultrasonic types. They provide standardized, repeatable motion patterns for the stacked sieve arrays through mechanical devices. The base, located at the bottom of the sieve assembly, receives all the final undersize material passing through the finest sieve, preventing material loss and facilitating collection. The sieve cover, on the top layer, prevents sample leakage during vibration and also prevents environmental contaminants from entering. Spacer rings connect and seal the sieve frames. A brush cleans the sieves; a soft-bristled brush should be used to avoid damaging the fine sieve. A balance weighs the oversize and undersize materials at each sieve layer and records and analyzes the data.

Material screening test sieves are used in almost all industries involving granular and powdered materials. In building materials, they analyze the gradation of sand, gravel, cement, and asphalt mixtures, which is fundamental to ensuring concrete strength and pavement quality. In chemicals and plastics, they determine the particle size distribution of resins, pigments, powder coatings, and various chemical raw materials, directly affecting product flowability, reactivity, and final properties. In the food industry, they are used for particle size control of flour, sugar, salt, spices, and grains to ensure taste and processing characteristics. The pharmaceutical industry has extremely strict requirements for particle size. Material screening test sieves are used to monitor the particle size of active pharmaceutical ingredients (APIs) and excipients, as this directly affects drug dissolution rates and bioavailability.

Some suppliers provide material screening test sieves and related equipment. Others specialize in manufacturing high-precision, durable equipment. Our factory provides test sieves that meet ISO and ASTM standards, offering advantages such as high cost-effectiveness and strong customization capabilities. We also provide sieve customization services, including special aperture sizes, special materials, electroformed mesh, and high-temperature corrosion-resistant materials, to meet various needs in laboratory and production environments.

Material screening test sieves consist of sieves fixed within a circular metal frame, offering a variety of mesh sizes. The sieves use metal wire mesh mounted on a rigid frame, coupled with a robust stainless steel sieve frame, providing high stability. From its precise aperture range and durable material selection to its standardized frame design; from rigorous screening procedures to a complete system consisting of a vibrating screen, chassis, and screen cover, every aspect reflects a pursuit of data accuracy and comparability, making it a reliable testing solution for product and material testing.

Mechanical Sieve Shaker for Particle Analysis

Mechanical Sieve Shaker for Particle Analysis plays a central role in this process...

Wet sieving concrete is a test method that involves grading freshly mixed concrete or concrete samples through a sieve in water...

lab test sieve with material is used for sieving powders with uniform particle size and relatively regular shape...

material test sieve with sample

material test sieve with sample analyzes samples such as sand, quartz, fertilizer, and seeds to analyze particle size...

material test sieve with sample

material test sieve with sample analyzes samples such as sand, quartz, fertilizer, and seeds to analyze particle size...

Dahan Machinery provides soil sieves of various specifications and models to meet the screening needs of different particle sizes and...

Laboratory Sieve Shaker Machine Price

Laboratory sieve shaker machine is a device used for laboratory sieving and particle analysis...

Nov 21, 2025

material screening test sieve consists of a robust stainless steel sieve frame and a wire mesh, with ...

Nov 20, 2025

vibration sieve for material testing

Vibration sieve for material testing is used for sample preparation of solid or bulk materials, enabl...

Nov 19, 2025

Lab test sieves with materials include brass, stainless steel, or brass frames with stainless steel m...

Nov 18, 2025

Wet sieving concrete is a sample pretreatment procedure that removes coarse aggregate from fresh conc...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap