Wednesday May-14 2025 16:10:11

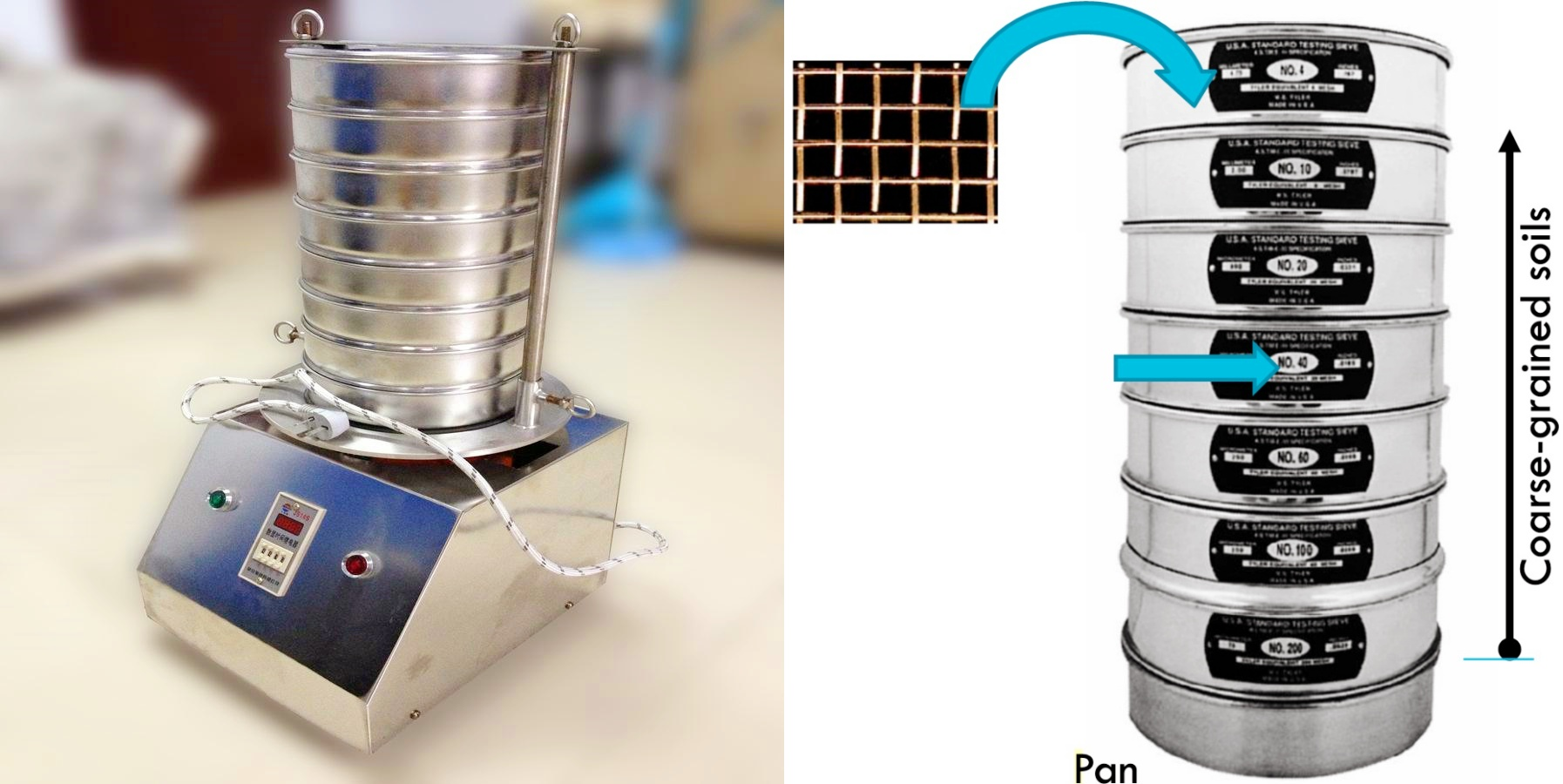

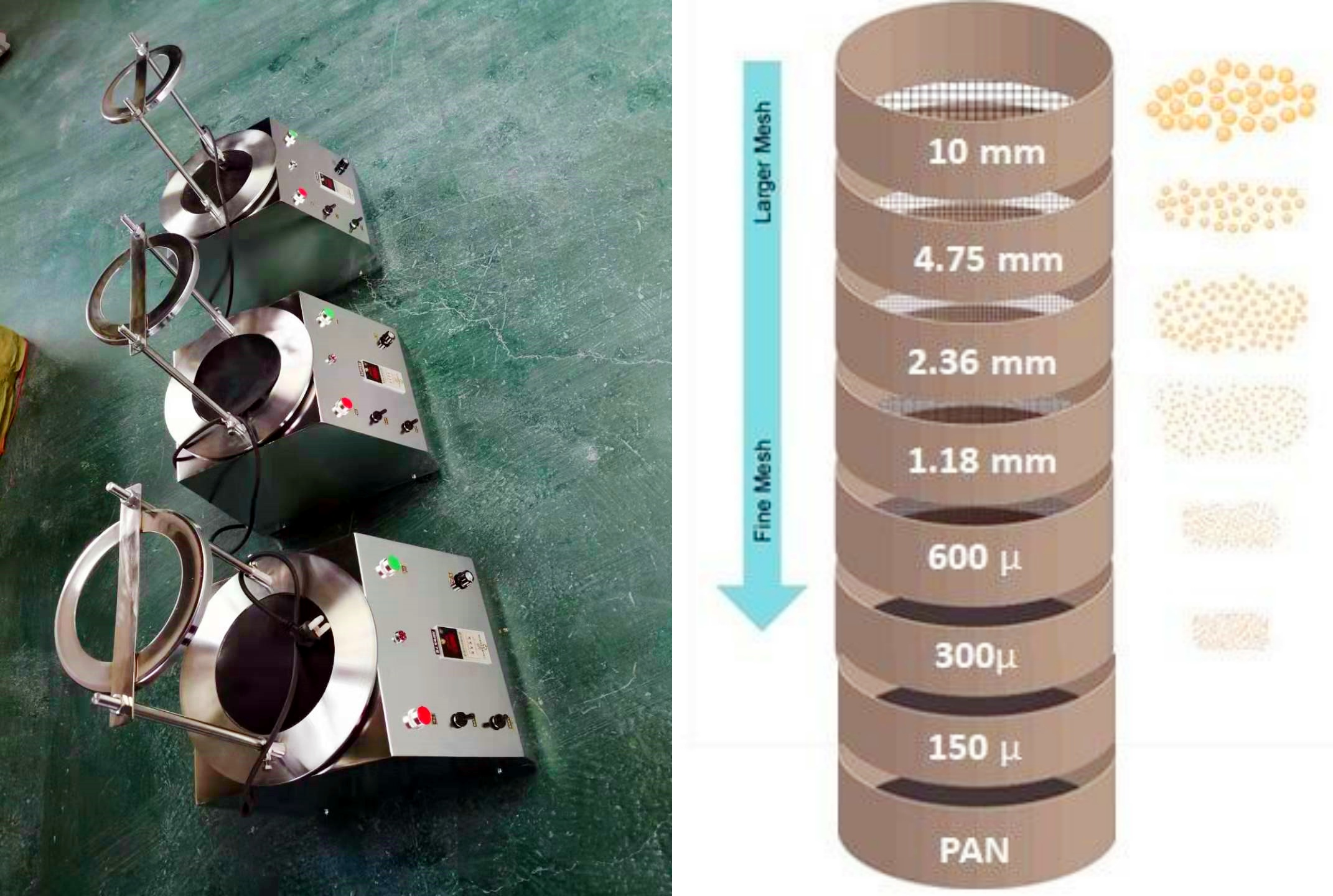

The test sieve for aggregate particle size is a set of wire mesh sieves that meet specific standards, designed to separate aggregate samples into different particle size ranges, so as to determine the particle size distribution of aggregate particles such as sandstone and crushed stone. These sieves are usually stacked from large to small according to the aperture size, and the aggregate particles are forced through the corresponding sieves by mechanical vibration. Commonly used sieve meshes include 4 mesh (aperture 4.75mm), 8 mesh (2.36mm), 16 mesh (1.18mm), 30 mesh (0.6mm), 50 mesh (0.3mm) and 100 mesh (0.15mm), etc., covering the detection needs of coarse aggregate to fine aggregate.

By screening the aggregate through the test sieve, its particle gradation (the distribution ratio of particles of different particle sizes) can be determined, and then:

Evaluate the quality of aggregate: whether it meets the engineering standards (such as the requirements of concrete and asphalt mixtures for aggregate gradation).

Guide the mix design: optimize the strength and durability of materials such as concrete and asphalt.

Quality control: ensure the stability of the particle size distribution of aggregates during production or construction.

①The test sieve consists of a series of sieves with different mesh sizes stacked in sequence.

②When the aggregate is placed on the top layer of the sieve and subjected to vibration, the aggregate particles smaller than the mesh size of this layer will pass through the mesh and fall to the next layer of the sieve, while the particles larger than the mesh size will be retained on this layer of the sieve. In this way, the aggregate will be retained on different sieve layers according to the particle size, and finally the purpose of grading by particle size is achieved.

③For example, when screening and analyzing coarse aggregate, the 5mm sieve will keep aggregate particles larger than 5mm in the upper layer, while particles smaller than 5mm will pass through the sieve holes and enter the next layer for further screening.

|

Sieve hole type |

sieve hole size (mm) |

mesh number (Mesh) |

nominal diameter range (mm) |

typical application scenarios |

|

Square hole sieve |

50.0 |

0.35 |

50.0 |

coarse aggregate (large particle size) |

|

37.5 |

0.5 |

37.5 |

concrete coarse aggregate |

|

|

25.0 |

0.71 |

25.0 |

asphalt mixture |

|

|

19.0 |

1 .0 |

19.0 |

roadbed materials |

|

|

9.5 |

2.0 |

9.5 |

ordinary concrete |

|

|

4.75 |

4.0 |

4.75 |

fine aggregate boundary |

|

|

2.36 |

8.0 |

2.36 |

sand for mortar |

|

|

1.18 |

16.0 |

1.18 |

fine sand gradation |

|

|

0.6 |

30.0 |

0.6 |

fine aggregate for cement concrete |

|

|

0.3 |

50.0 |

0. 3 |

Fly ash gradation |

|

|

0.15 |

100.0 |

0.15 |

Ultrafine material |

|

|

Round hole sieve |

53.0 |

0.35 |

53.0 |

Standard coarse aggregate |

|

37.5 |

0.5 |

37.5 |

Railway ballast |

|

|

31.5 |

0.6 |

31.5 |

Commercial concrete |

|

|

16.0 |

1.25 |

16.0 |

Ordinary sand and gravel |

|

|

5.0 |

4. 0 |

5.0 |

masonry mortar |

|

|

Square hole sieve |

63.0 |

0.25 |

63.0 |

standard coarse aggregate |

|

31.5 |

0.6 |

31.5 |

asphalt pavement |

|

|

16.0 |

1.25 |

16.0 |

concrete fine aggregate |

|

|

8.0 |

2.5 |

8.0 |

filter material |

|

|

4.0 |

5.0 |

4.0 |

cement mortar |

Manual operation error: The screening process of the test sieve usually requires manual operation, including placing the aggregate sample on the sieve, vibrating the sieve, and weighing the weight of the aggregate on and under the sieve. Manual operation may cause some errors, such as uneven sample placement, inconsistent vibration intensity and time, and weighing errors, which will affect the accuracy and repeatability of the particle size results.

Insufficient sample representativeness: If the test sieve for aggregate particle size is not adequately sampled or the particles are stratified during screening (such as vibration causing fine particles to sink), the results may deviate from the true distribution. The sample may not be used for other experiments after screening (such as fragile particles being destroyed).

Limited particle size range: The minimum sieve hole limit of the test sieve is usually 75μm (200 mesh), and finer particles (such as powders) cannot be effectively separated and need to rely on sedimentation methods. The upper limit of large particles is fixed, the maximum sieve size is limited, and oversized particles need to be crushed in advance or other methods are used.

Not suitable for some special aggregates: For some aggregates with irregular shapes, high viscosity or special physical properties, the screening effect of the test sieve may not be ideal. For example, flake or needle-shaped aggregates may get stuck at the sieve hole, affecting the smooth screening; viscous aggregates are easy to agglomerate and difficult to pass through the sieve hole, resulting in inaccurate particle size results.

In concrete production, aggregate particle size can optimize aggregate grading to make concrete have good workability, strength and durability. For road engineering, suitable aggregate particle size distribution can ensure the flatness, skid resistance and bearing capacity of the road surface.

In mining, test sieves for aggregate particle size help to understand the particle size distribution of ore, provide a basis for ore dressing processes such as crushing and grinding, and improve ore dressing efficiency and resource recovery rate.

In industries such as glass manufacturing and ceramic production, particle size of raw aggregates is also crucial, which affects the quality and performance of products. For example, in glass production, precise control of the particle size of aggregates such as quartz sand can improve the transparency and uniformity of glass.

In the field of building material testing, test sieve for aggregate particle size usually refer to a set of standard sieves used to perform particle size distribution analysis of coarse aggregates (such as crushed stone, sand and gravel) or fine aggregates (such as sand) by screening. By properly applying the test sieve, accurate control of aggregate particle size distribution can be ensured, thereby improving the performance of engineering materials and construction quality.

What is the wet sieving process?

Wet sieving process is a sieving process assisted by a liquid (usually water or a solution containing a dispersant) to more effectively...

Fines content tester can be defined as an instrument used to quantitatively determine the content of fines powder components of a specific fineness...

Micro silica powder particle size analysis test sieve

Micro silica powder, also known as silica fume, is an ultrafine active silica material with a very small particle size, usually between 0.1-0.3 microns, which...

Agricultural gruesos Test sieves

Agricultural gruesos test sieves are experimental equipment used for particle size analysis, grading and testing of agricultural soil, gruesos...

Stainless steel frame and woven cloth

The test sieve is a laboratory equipment used for particle size analysis. Its core components usually include a stainless steel frame and woven cloth (also called a sieve)...

Test sieve for pharmaceutical powder

Test sieve for pharmaceutical powder is a special equipment used in the pharmaceutical industry for screening and detecting the particle size of pharmaceutical powder. Its main...

May 14, 2025

test sieve for aggregate particle size

The test sieve for aggregate particle size is a standard sieve used to evaluate the particle size dis...

May 13, 2025

Test sieve for pharmaceutical powder

Test sieve for pharmaceutical powder is a special equipment used in the pharmaceutical industry for a...

May 12, 2025

Test sieve for cement fineness

Test sieve for cement fineness is a key tool for evaluating cement particle size distribution and gri...

May 10, 2025

The test sieve for sand grading is a device that uses mechanical vibration and multi-layer standard s...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap