Saturday May-10 2025 18:14:00

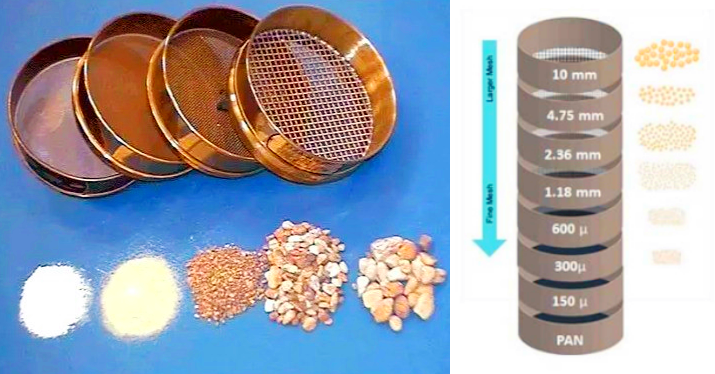

Test sieve for sand grading is a test device that separates sand particles by sieve hole size. It is used to analyze the particle grading and fineness modulus of sand. It is widely used in building materials, engineering and mining fields. Its core is a multi-layer standard sieve. The commonly used test sieve aperture is 200mm or 300mm. The sieve aperture size (mesh number) ranges from 4 mesh (4.75mm) to 200 mesh (0.075mm), which can accurately adjust sand, river sand, etc.

The purpose of test sieve for sand grading is to determine the content ratio of particles of different particle sizes in sand, which is called particle size distribution or grading. sieveing analysis through standard sieves can evaluate the quality of sand and determine whether it meets specific engineering or production requirements. For example, in concrete production, the grading of sand directly affects the density, strength, working performance and economy of concrete.

The working principle of the sand grading test sieve is mainly based on mechanical vibration and standard sieves to separate the sand samples by particle size. The core is to use standard sieves with different aperture sizes to make the sand particles move on the sieve surface by applying vibration, so as to achieve grading by particle size.

①Effectively intercept impurities in sand

The detection sieve can effectively intercept impurities mixed in the sand. Impurities such as soil, stones, and wood chips usually have different particle sizes from sand. During the sieveing process, these impurities will be retained on the surface of the sieve or separated through sieves with different apertures, avoiding impurities from entering the subsequent conveying process and improving the purity and quality of the sand.

②Reduce differential wear of sand particles

Unclassified sand contains a mixture of large and small particles. During the conveying process, large particles of sand may cause greater wear on the conveying equipment, while small particles of sand may accumulate in the gaps of the equipment, accelerating the damage of the equipment. After the detection sieve classifies the sand, the particle size of the sand entering the conveying equipment is relatively uniform, reducing the uneven wear of the equipment caused by differences in particle size.

③Solve the uneven size of sand particles

The detection sieve has sieves with different apertures, which can accurately classify the sand according to its particle size. For example, common test sieves for sand grading have sieve holes of different specifications such as 4.75mm, 2.36mm, and 1.18mm. Through the combination of multiple layers of sieves, sand can be accurately divided into grades with different particle size ranges, such as coarse sand, medium sand, and fine sand, thereby solving the problem of uneven sand particle size and meeting the strict requirements of different projects for sand particle size.

④ Improve the pertinence of transportation

The sand after being graded by the test sieve has a more uniform particle size. During the transportation process, appropriate conveying equipment and conveying parameters can be selected according to the characteristics of different particle size grades. For example, for coarse sand, a conveyor belt with a larger diameter can be used to reduce the possibility of blockage; for fine sand, the conveying speed and conveying volume can be appropriately adjusted to avoid sand flying due to too fast flow rate or poor conveying due to too large conveying volume.

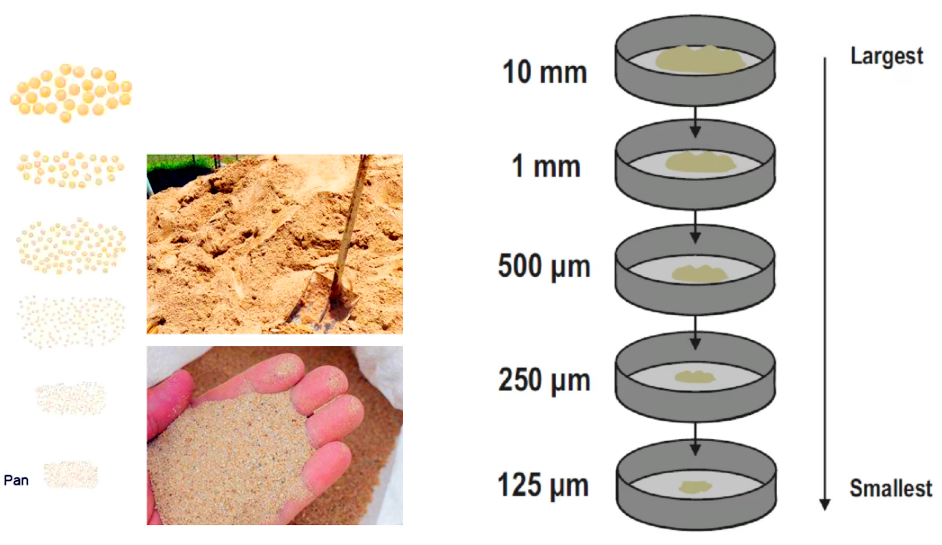

Sand grading is usually carried out using a set (series) of standard sieves. This set of sieves is stacked in descending order of sieve hole size, with the largest sieve on top and the smallest sieve on the bottom. A sieve bottom plate is placed at the bottom to collect fine material passing through all sieves. Typical sieving steps include:

Prepare a certain amount of representative dry sand sample.

Put the sand sample into the sieve on top of the stacked standard sieves.

The commonly used mechanical sieving instrument vibrates the sieve stack. The vibration causes the sand particles to move on the sieve surface, and particles smaller than the sieve holes pass through the sieve holes and fall onto the next sieve, while particles larger than the sieve holes remain on the current sieve. After a certain period of sieving, weigh the mass of sand remaining on each sieve and in the sieve bottom plate.

According to the mass of sand retained on each sieve and the mass of sand passing through the sieve bottom, calculate the percentage of sand in each particle size (particles passing through a certain sieve but retained on the next sieve), and thus obtain the particle size distribution curve of the sand.

Sand grading for concrete and mortar: Construction sand must meet the particle size requirements of concrete or mortar, usually requiring the sand particle size to be between 0.15-4.75 mm, and is divided into coarse sand, medium sand, and fine sand. If the sand contains too much fine powder or large particles, it will affect the strength of concrete or the fluidity of mortar. Through vibration sieveing, the sand is divided into different grades according to the particle size (such as medium sand 0.5-1 mm, fine sand 0.15-0.5 mm) to avoid uneven particles leading to insufficient concrete strength or mortar cracking.

Mining and machine-made sand production: Machine-made sand is made by crushing stones (such as granite and lime), containing a large amount of stone powder (<0.075 mm) or size stone particles, and needs to be graded for different uses (such as highways and railway ballast). The test sieve for sand grading can solve the problem of excessive sand caused by excessive stone powder; realize the production of multi-specification sand to meet different engineering needs; reduce equipment blockage and improve continuous production capacity.

Sand classification for river dredging: The sand produced by river dredging has a high water content and is mixed with large silt, shells, etc. It needs to be layered before being used for dam construction or land reclamation. The detection sieve used for sand classification can classify and grade wet sand, and sieve out silt and shells. The role of the grading sieve is suitable for processing sand in the aperture, solving the problem of large wet sand sieveing entrance and high mud content; achieving rapid blocking and grading, and improving sand utilization.

Test sieve for sand grading is one of the core equipment in the sand processing process. It sieves and grades sand according to particle size by physical and mechanical means. In different application scenarios, the model, number of layers, sieve material and mesh size of the detection sieve will be specially designed and adjusted according to the required sand specifications and processing volume. For specific scenarios (such as sand production lines), in-depth discussion of equipment selection or parameter optimization is required. Please provide more details so that we can further analyze the mechanism!

What is the wet sieving process?

Wet sieving process is a sieving process assisted by a liquid (usually water or a solution containing a dispersant) to more effectively...

Fines content tester can be defined as an instrument used to quantitatively determine the content of fines powder components of a specific fineness...

Micro silica powder particle size analysis test sieve

Micro silica powder, also known as silica fume, is an ultrafine active silica material with a very small particle size, usually between 0.1-0.3 microns, which...

Agricultural gruesos Test sieves

Agricultural gruesos test sieves are experimental equipment used for particle size analysis, grading and testing of agricultural soil, gruesos...

Stainless steel frame and woven cloth

The test sieve is a laboratory equipment used for particle size analysis. Its core components usually include a stainless steel frame and woven cloth (also called a sieve)...

Test sieve for soil analysis is an important tool for soil particle size distribution analysis. Its main function is to grade and sieve soil samples.

May 10, 2025

The test sieve for sand grading is a device that uses mechanical vibration and multi-layer standard s...

May 09, 2025

Test sieve for soil analysis is a key tool for soil particle size distribution analysis. It grades so...

May 08, 2025

Herbal Powder Lab Sieve Shaker

The herbal powder lab sieve shaker is a laboratory equipment specially used for screening, impurity r...

May 07, 2025

Stainless Steel Grain Granule Test Sieve for Lab

Stainless steel grain granule test sieve for lab is a key analytical tool. Through different mesh siz...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap