Saturday May-17 2025 16:54:33

The test sieve for sieving corundum is a laboratory screening tool used to detect the particle size distribution of corundum particles. It is widely used in abrasives, building materials, metallurgy and other industries. The sieve is usually composed of a stainless steel sieve frame and a high-precision wire mesh. The standard diameter is mostly 200mm, and the mesh aperture ranges from 0.02mm (about 635 mesh) to 5mm (about 4 mesh). Screens of different mesh sizes can be stacked and used in combination according to the detection requirements. During the screening process, the sample is screened layer by layer in conjunction with a vibrating screen to achieve screening and weighing analysis of corundum of different particle sizes.

The working principle of test sieve for sieving corundum is based on the mechanism of particle screening and physical grading. Vibration is used to make corundum (silicon carbide) particles layered on sieves of different apertures to achieve particle size distribution analysis. The specific steps are as follows:

① Sample placement Placement: Place the dry corundum sample (usually 100-500g) on the top sieve, and the sieves are arranged from top to bottom according to the aperture from large to small (for example, 63mm to 0.045mm, 1/4 inch to 325 mesh).

② Vibration: The equipment generates regular vibrations (usually 100-300 times/minute) through an electric vibrator to move the particles on the sieve. Vibration causes the particles to pass through the sieve holes or stay on the corresponding sieve according to their size.

③ Particle classification: Larger particles are intercepted by the upper large-aperture sieve, and smaller particles pass through the lower small-aperture sieve layer by layer, and finally classified by particle size. The screening time is usually 3-5 minutes to ensure sufficient separation.

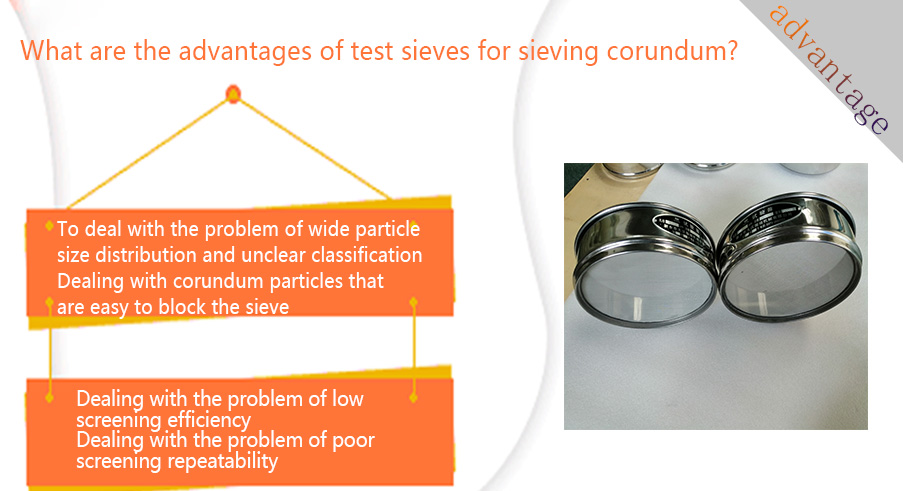

To deal with the problem of wide particle size distribution and unclear classification: corundum is often a mixed particle size material with a large particle size span, which is difficult to classify by a single-layer sieve. Effective grading. The test sieve for sieving corundum adopts a combination of multi-layer standard test sieves (such as 16 mesh, 24 mesh, 36 mesh, 60 mesh, etc.), and is layered from large to small according to the particle size, effectively realizing the step-by-step screening of particles. Precise sieve hole control, the sieve hole error is less than ±0.02mm, ensuring clear screening boundaries.

Dealing with corundum particles that are easy to block the sieve: corundum particles have high hardness and irregular shape, and are easy to get stuck in the sieve holes, especially in fine mesh sieves. The sieve is made of stainless steel woven mesh, which has strong rigidity, good wear resistance, and high anti-blocking performance; it can be used with a vibrating screen machine to force particles out of the sieve holes through high-frequency vibration and reduce the chance of clogging.

Dealing with the problem of low screening efficiency: manual screening takes a long time, has poor accuracy, low efficiency, and is prone to screening leakage or repeated screening. The test sieve for sieving corundum is equipped with an electric standard vibrating screen machine to complete high-efficiency screening within the specified time. Screening improves the particle passing rate; the sieve structure is tightly locked to prevent material leakage or inter-layer material cross-linking during screening.

Dealing with the problem of poor screening repeatability: manual screening operations are inconsistent, and test results of different personnel fluctuate greatly, affecting the accuracy of detection. The sieve and vibrating screening equipment of the test sieve for sieving corundum meet the standards to ensure the uniformity of the screening method; parameters such as screening time, amplitude, and sample volume can be controlled and standardized to ensure that the results have good repeatability and comparability.

The particle size range of corundum is relatively wide, and different uses have different particle size requirements. Therefore, the mesh number of the test sieve should be selected according to the grade and use of corundum. The following is the recommended test sieve mesh number range for common corundum screening, for reference only:

|

Mesh number (mesh) |

corresponding aperture (mm) |

applicable particle size level |

|

4 mesh |

4.75 mm |

coarse grain diamond (such as rail anti-skid, etc.) |

|

8 mesh |

2.36 mm |

coarse grain abrasive |

|

16 mesh |

1.18 mm |

medium coarse abrasive |

|

24 mesh |

0.71 mm |

medium abrasive |

|

36 mesh |

0.425 mm |

medium fine abrasive |

|

60 mesh |

0.25 mm |

fine abrasive |

|

80 mesh |

0.18 mm |

ultra-fine sandblasting/polishing |

|

100 mesh |

0.15 mm |

fine diamond |

|

150 mesh |

0.106 mm |

ultra-fine particle detection |

|

200 mesh |

0.075 mm |

Sieving of ultra-fine powder |

(Note: The specific mesh number and aperture of the sieve should be determined according to the particle size range of corundum)

It is generally recommended to combine 6~8 layers of sieves (such as: 10 mesh, 16 mesh, 24 mesh, 36 mesh, 60 mesh, 100 mesh, 200 mesh) to cover a wider particle size range;

The bottom is equipped with a material tray and the top is equipped with a sieve cover to prevent leakage and splashing;

For specific particle size grades (such as 24# corundum), it is recommended to select a combination of 2~3 meshes adjacent to each other to ensure screening accuracy.

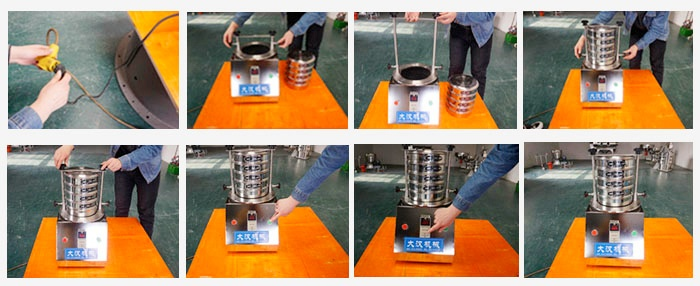

The use of the test sieve for sieving corundum mainly includes the following steps to ensure efficient and accurate particle size analysis:

Preparation: Confirm that the test sieve is intact and the sieve is not damaged or blocked. The commonly used sieve aperture range is 0.045mm (325 mesh) to 63mm (1/4 inch). According to the corundum particles According to the particle size requirements, select the appropriate mesh size (such as 60 mesh, 120 mesh, 200 mesh, etc.), and stack them from top to bottom according to the aperture from large to small. Take 100-500g of dry corundum sample, avoid moisture to prevent the sieve hole from being blocked.

Combined sieve: According to the required particle size range, stack several test sieves with different apertures in order from large to small, and place the receiving tray on the bottom layer. Adjust the equipment parameters, the vibration frequency is generally set to 100-300 times/minute, and the screening time is 3-5 minutes.

Screening operation: Put the sample evenly into the top sieve, start the equipment, vibrate or tap to make the particles stratify by size. Ensure that there is no overflow during the screening process, and screen in batches if necessary.

Result collection: After the screening is completed, collect the particles on each layer of the sieve and weigh them separately.

Weighing analysis: After the screening is completed, weigh the sieve residues on each layer and calculate the proportion of each particle size grade.

Carbon sand production and processing industry: used to detect whether the particle size of the newly purchased corundum raw materials meets the production requirements, and to prevent unqualified raw materials from entering the production process. In the production links of corundum such as crushing, grinding, and grading, the test sieve is regularly used to monitor the particle size distribution of the product to ensure the stability of the production process and the consistency of product quality. The test sieve for sieving corundum can also be used to analyze the particle size characteristics of corundum produced under different process conditions, and provide data support for the research and development of new products.

Abrasives and abrasive tools industry: Accurately sort corundum abrasives of different particle sizes for the manufacture of various specifications of grinding wheels, sandpaper, sanding belts and other abrasive products. Detect whether the particle size distribution of corundum abrasives in abrasive tools is uniform to ensure the grinding performance and service life of abrasive tools.

Polishing materials industry: used to control the particle size of corundum polishing powder to meet the polishing requirements of different materials and surface finishes. Light requirements, such as precision polishing of metals, glass, ceramics, etc.

Wear-resistant materials industry: When preparing materials such as corundum wear-resistant floors and wear-resistant coatings, analyze the particle size of corundum fillers to optimize the performance of the materials.

Scientific research and education: In the field of material science research, it is used to study the influence of the particle size characteristics of corundum on its physical and chemical properties. The test sieve can also be used as a common tool for particle size analysis and used in teaching experiments of related majors.

In short, the test sieve for sieving corundum minimizes the problems that may occur during the screening process through precise manufacturing, reasonable structural design, professional screening equipment and scientific operation methods, and ensures the accuracy and reliability of corundum particle size analysis. At the same time, operators also need to pay attention to daily maintenance and timely discover and solve potential problems to ensure the good operation of the test sieve.

What is the wet sieving process?

Wet sieving process is a sieving process assisted by a liquid (usually water or a solution containing a dispersant) to more effectively...

Fines content tester can be defined as an instrument used to quantitatively determine the content of fines powder components of a specific fineness...

Micro silica powder particle size analysis test sieve

Micro silica powder, also known as silica fume, is an ultrafine active silica material with a very small particle size, usually between 0.1-0.3 microns, which...

Agricultural gruesos Test sieves

Agricultural gruesos test sieves are experimental equipment used for particle size analysis, grading and testing of agricultural soil, gruesos...

Stainless steel frame and woven cloth

The test sieve is a laboratory equipment used for particle size analysis. Its core components usually include a stainless steel frame and woven cloth (also called a sieve)...

Test Analysis sieves For Fine-Grained Soil

The test analysis sieve for fine-grained soil (sieving method) is an important method for determining the particle size distribution of soil in geotechnical tests. It is...

May 17, 2025

test sieve for sieving corundum

The test sieve for sieving corundum is a laboratory tool widely used in abrasives, building materials...

May 16, 2025

Test Analysis sieves For Fine-Grained Soil

The test analysis sieve for fine-grained soil is a key tool for determining the particle size distrib...

May 15, 2025

Test sieve for flour quality control

The test sieve is an indispensable key screening equipment in flour quality control. It can grade and...

May 14, 2025

test sieve for aggregate particle size

The test sieve for aggregate particle size is a standard sieve used to evaluate the particle size dis...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap