Tuesday February-03 2026 17:34:10

Aggregate Testing Equipment for Construction Materials is used in construction engineering to conduct a series of performance tests and quality assessments on aggregate raw materials and finished products. Its function is to control aggregate quality, ensuring it meets the needs of different construction projects and providing a foundation for the stability, safety, and durability of engineering structures. Aggregates are the most abundant basic materials in construction engineering, made from rocks, ores, etc., through crushing and screening. They are divided into coarse and fine aggregates and are important components of concrete, mortar, asphalt mixtures, and other materials.

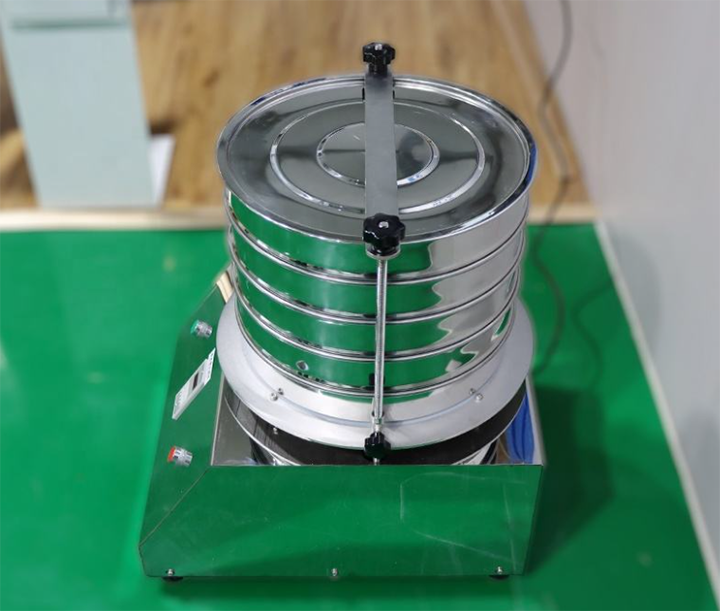

Aggregate testing focuses on indicators such as particle size distribution and mud content to determine whether the aggregates meet construction requirements. Testing sieves are used to test aggregate particle size distribution, separating the aggregates through vibration to help understand the particle size distribution. The sieves are generally made of stainless steel or brass, which are wear-resistant and corrosion-resistant, with precise mesh sizes. Common diameters are 200mm and 300mm, and apertures range from 0.075mm to 63mm, suitable for screening aggregates of different particle sizes.

Various tools and equipment are used when measuring aggregates. Aggregate Testing Equipment for Construction Materials is divided into two categories: basic testing tools and specialized testing equipment. Basic tools include sieves of different sizes used in conjunction with testing sieves to separate aggregates into layers through vibration. Soft brushes are used to clean residual powder from the sieve openings to prevent clogging and affecting results. Trays and scoops facilitate sampling, loading, and handling. Specialized equipment is more diverse. In addition to testing sieves, there are electronic balances for weighing aggregates, forced-air drying ovens for drying, Leigh flasks for measuring apparent density, sand and gravel mud content analyzers and electric vibrating sieves for checking mud content and particle shape, and needle-and-flaky particle gauges for measuring the needle-and-flaky particle content of coarse aggregates. Using these devices together allows for accurate assessment of various aggregate indicators.

Using Aggregate Testing Equipment for Construction Materials offers numerous benefits, including improved project quality and cost-effectiveness. These devices provide accurate and highly repeatable data, unlike manual judgment which is prone to subjective errors. The equipment operates according to national or international standards, ensuring more reliable test results. By testing aggregate particle size distribution, impurity content, and other indicators, engineers can adjust concrete mix proportions to improve structural compressive and flexural strength, reducing cracking and spalling. Furthermore, the system's testing helps engineers utilize aggregates of different sizes efficiently, minimizing waste. Timely testing during material procurement can prevent the use of substandard aggregates, avoiding rework or additional costs associated with later maintenance. The equipment is easy to operate, highly automated, fast-paced, and has a short testing cycle, ensuring timely project progress.

Currently, suppliers of aggregate testing equipment for construction materials include professional instrument manufacturers and comprehensive construction testing equipment companies. Some suppliers also offer customized equipment to suit different testing scenarios. Dahan Machinery has mature manufacturing and production capabilities, providing a complete set of aggregate testing equipment that meets national testing standards. The equipment is guaranteed in terms of accuracy, stability, and durability. The company also has a pre-sales technical consulting team that will recommend suitable equipment configurations based on the client's construction needs and testing scale, and provide after-sales service. When selecting equipment, customers need to examine the supplier's qualifications and service system to ensure that the purchased equipment is easy to use and maintain.

Aggregate Testing Equipment for Construction Materials is frequently used in engineering construction. In large infrastructure projects, such as highways, high-speed railways, cross-sea bridges, or airport runways, this equipment is used to test aggregate quality to ensure that concrete can withstand vehicle loads and weathering. In real estate development, from foundation treatment to main structure construction, supervision units also check aggregate particle size, mud content, and other indicators. In commercial concrete mixing plants, each batch of aggregate undergoes screening and mud content testing before use to ensure stable concrete performance. The equipment is also commonly used in geological exploration, mining, or building materials quality inspection centers. During use, relevant standards such as ASTM C136 and ASTM C131 must be followed to ensure concrete quality and provide reliable data support for project safety.

Aggregate Testing Equipment for Construction Materials plays a fundamental role in ensuring the quality of construction projects. As a component of building materials, aggregate performance needs to be evaluated using sieves, testing sieves, and various auxiliary equipment. The material and aperture precision of the sieves significantly impact the accuracy of gradation analysis results. Common tools range from soft brushes for cleaning sieves to abrasion testing machines for assessing aggregate durability; each piece of equipment serves a specific purpose in the testing process. Using these devices not only helps improve structural safety but also reduces material waste. Users must select equipment from different suppliers based on actual process requirements, production capacity, and relevant standards, adhering to national and international regulations during construction and testing to ensure reliable test data and support stable and continuous improvement of project quality.

When testing samples, sample test sieve machine is typically used to sieve them. Sieving determines whether the sample's particle size...

vibrate test sieve for bulk material

vibrate test sieve for bulk material is a device used for screening or particle size analysis of granular, powdery, and other bulk materials...

test sieve for particle analysis material

test sieve for particle analysis material can be used for sieving and particle size analysis of granular materials such as mung beans, soil, and sand...

material separation test sieve

material separation test sieve separates materials such as powders, granules, and sand through sieving, thereby determining the particle size distribution or removing impurities...

Feb 03, 2026

Aggregate Testing Equipment for Construction Materials

Aggregate Testing Equipment for Construction Materials is equipment used to perform performance testi...

Feb 02, 2026

International Standard Laboratory Stainless Steel Test Sieve

International Standard Laboratory Stainless Steel Test Sieve is a screening tool used to analyze the ...

Jan 27, 2026

vibratory test sieve with sample loading

vibratory test sieve with sample loading involves loading the sample to be sieved into a vibrating si...

Jan 20, 2026

When testing samples, a sample test sieve machine is usually used to sieve the samples. By sieving, i...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap