![[field:title/]](/uploads/allimg/250430/2-250430164H70-L.png)

Tap Sieve Shaker is a device used for laboratory particle size analysis. It sieves samples such as powders and granules by simulating manual tapping and vibration. Its price ranges from $20 to $3000.

Number of sieve layers: usually 6-13 layers

Common diameter: 200mm, 300mm, 400mm, etc.

Knocking frequency: about 60 times/minute

Rotation frequency: about 278 times/minute

Power supply: 220V / 50Hz

Rotation stroke: 25mm

Tap Sieve Shaker is a commonly used particle size analysis device in laboratories. It sieves powders and granular samples by combining up-and-down tapping and circular motion. When selecting a model, consider the sample's particle size range, the required screening accuracy, and the characteristics of the material being tested (such as adhesion and static charge). For applications requiring high precision and prone to clogging, the Tap Sieve Shaker is the preferred choice, as its unique tapping function ensures effective sieving.

Tap sieve shaker (also known as a vibrating sieve or sieving machine) is a device that uses a motor or mechanical device to make the sieve vibrate periodically. It uses mechanical vibration or swing to achieve particle material screening, classify particles according to different particle sizes, and make the sieve move on the surface of the sieve to achieve the purpose of screening. It is often used in experiments, mineral processing, chemical industry, pharmaceuticals, food and other fields. Its core function is to achieve classification or purification through the physical properties of different particles (such as density and particle size).

Laboratory shakers and industrial sieving equipment differ significantly in design and application. Laboratory shakers prioritize accuracy and controllability and are typically used in research, quality control, and other applications requiring precise particle size analysis. These devices are equipped with digital control panels. In contrast, industrial sieving equipment prioritizes durability and high throughput. They often operate in harsh production environments and process large volumes of material, thus utilizing more robust construction and powerful drive systems. The mesh size and number of sieving stages can be flexibly customized to meet specific material characteristics and production requirements, enabling rapid material sizing.

|

Classification |

Type |

Features |

Application scenarios |

|

Laboratory sieve shaker |

Circular shaker |

Fixed circular trajectory oscillation, adjustable speed (such as 40-200rpm), suitable for mixing and culture |

Cell culture, molecular hybridization, chemical experiments |

|

Laboratory tap sieve shaker |

Reciprocating shaker |

Linear reciprocating motion, suitable for samples that require strong mixing |

Protein extraction, enzyme reaction |

|

Laboratory sieve shaker |

3D shaker |

3D oscillation, suitable for complex sample mixing or special experimental needs |

Microbial fermentation, tissue culture |

|

Laboratory tap sieve shaker |

microplate shaker |

specially designed for microplate, small oscillation amplitude, high frequency, suitable for high-throughput screening |

drug screening |

|

Classification |

Picture |

Type |

Features |

Application scenarios |

|

Industrial screening shaker |

|

Circular vibrating screen |

Multi-layer screen, eccentric shaft excitation, high screening efficiency, suitable for bulk material classification |

mining, building materials, chemical industry (such as quartz sand, ore screening) |

|

Linear vibrating screen |

|

Linear vibration |

suitable for fine particles or powder materials, high screening accuracy |

food, pharmaceutical, chemical industry (such as flour, plastic particles) |

|

Roller screen |

|

Roller rotation drives material screening |

suitable for sticky or bulk materials |

garbage disposal, preliminary ore sorting |

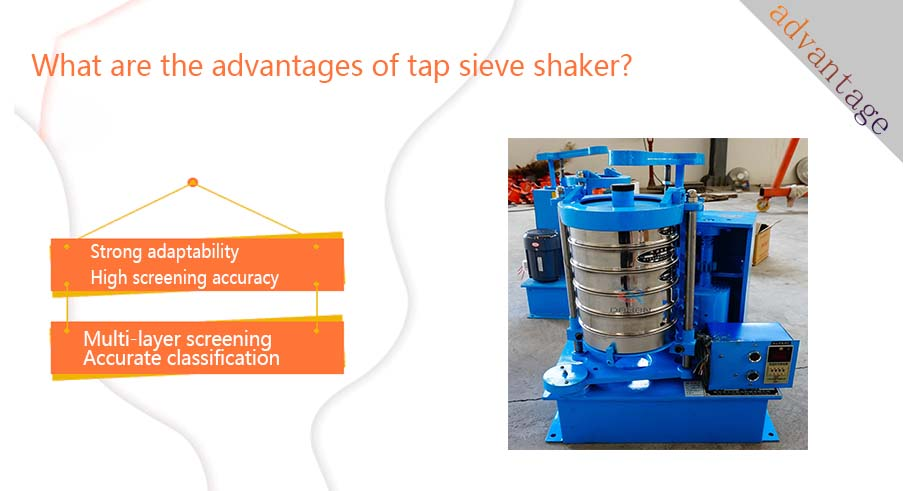

The Tap Sieve Shaker's key features lie in its excellent adaptability, high precision, multi-layer screening capabilities, and accurate classification. It accommodates sieves of varying diameters and number of layers. By combining vibration and tapping, it accurately classifies a variety of materials, including dry powders, wet powders, and granules. It is a powerful tool for particle size analysis in scientific research, quality control, and other fields.

Strong adaptability: It can be equipped with tap sieve shakers of various diameters (such as Φ200mm, Φ300mm) and different numbers of layers, and has good adaptability to dry powder, wet powder and small particles.

High screening accuracy: It adopts electromagnetic or mechanical vibration, and the screening action is stable, which can realize the classification analysis of fine particles, and is particularly suitable for particle size distribution testing, scientific research or precision product screening.

Multi-layer screening: Multi-layer sieves (generally 1~8 layers) can be installed, and multiple particle size levels can be screened at one time, which improves efficiency and saves manpower and screening time.

Accurate classification: Tap sieve shaker uses its own vibration and the effect of water flow to accurately classify the particle size of the material. It can separate particles of different particle sizes more accurately to meet the strict requirements of subsequent processes on the particle size of the material.

|

Technical parameters |

Description/range |

Technical parameters |

Description/range |

|

Sieve diameter |

Ø200mm, Ø300mm, Ø400mm, Ø200mm |

Number of sieve layers |

1–8 layers |

|

Maximum sample loading |

1–3kg (laboratory) |

Vibration mode |

Electromagnetic vibration/mechanical shaking/up and down vibration |

|

Vibration frequency |

1400–3000 times/minute |

Amplitude |

0.5–3mm |

|

Timing function |

0–99 minutes can be set |

Power |

100–400W (laboratory) |

|

Power supply voltage |

220V/50Hz |

Machine weight |

25–60kg (experimental type) |

|

Noise level |

≤ 75dB |

Material |

Stainless steel/carbon steel |

Tap sieve shaker uses a motor to drive the center or weight device to make the screen move horizontally, vertically or in combination. This vibration can help the screen jump on the screen and pass through screens of different apertures to achieve particle size classification.

Through periodic vibration or horizontal/vertical shaking, the material moves on the screen or bed.

The particles are gradually layered due to differences in density and particle size. Fine particles pass through the sieve holes and coarse particles remain on the surface to achieve separation.

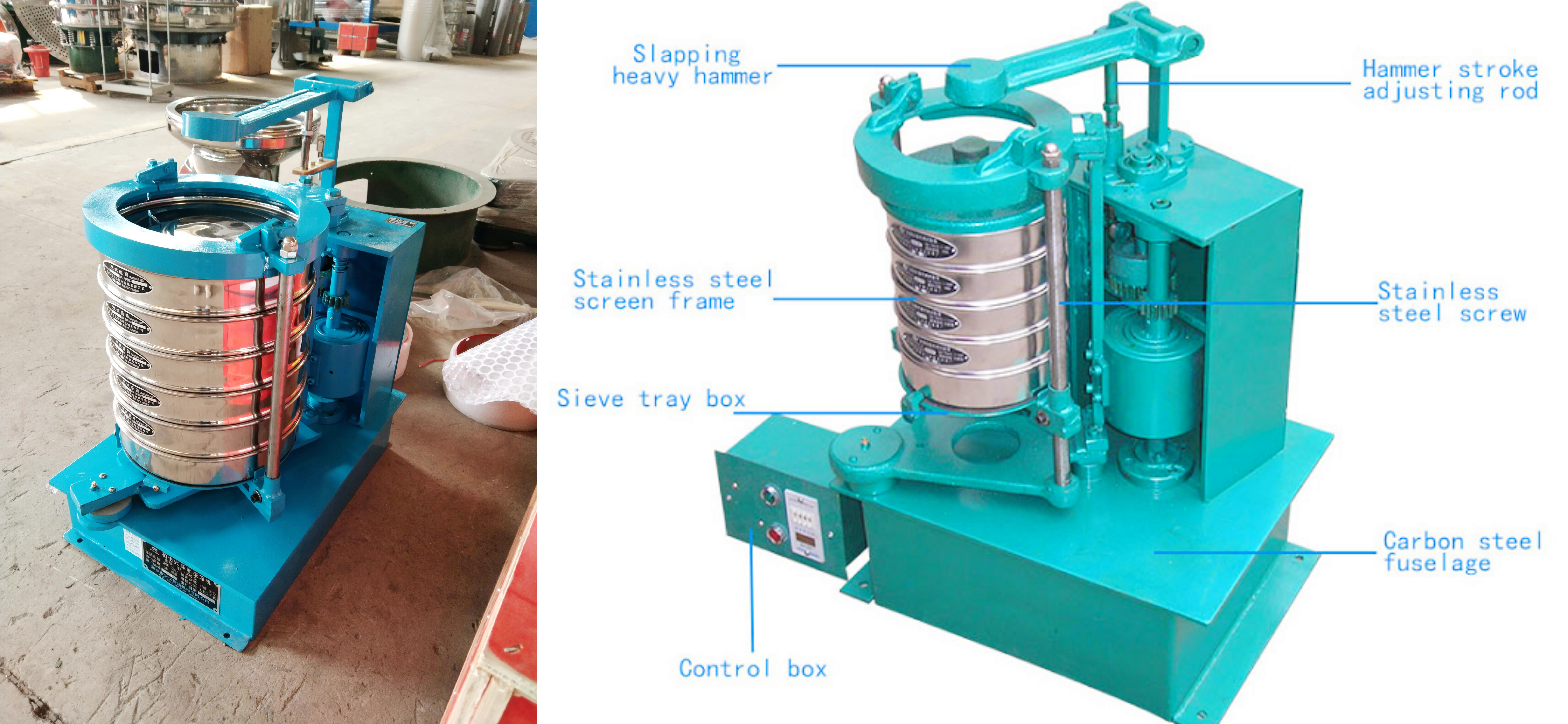

A Tap Sieve Shaker is a particle size analysis device commonly used in laboratories. It consists of four core components: a sieve bed that holds the sieves, a drive unit that provides vibration and impact, a control system for precise control of the sieving process, and a frame that ensures stable operation. These components work together to effectively and accurately sieve a variety of powders and granular materials.

Bed surface: usually a flat or slightly inclined platform on which a screen or container can be installed.

Drive device: provides vibration or shaking power, commonly motor drive, electromagnetic drive or crank connecting rod mechanism.

Control system: adjusts the vibration frequency, amplitude or running time.

Frame: supports the main body of the equipment to ensure stability.

The Tap Sieve Shaker's primary purpose is to accurately screen, grade, and control the quality of various materials. It plays a vital role in a wide range of industries and scenarios, particularly in applications requiring solid-liquid or solid-solid separations, enabling efficient gravity separation based on particle density, size, and shape. It has a wide range of applications, including warehouse material analysis, standard sieving tests, powder grading, quality control, and laboratory research.

Tap Sieve Shaker is widely used for particle size analysis, grading and screening, and quality control of various types of granular material warehouses. It is one of the standard equipment in laboratories and production processes. Tap sieve shaker plays an important role in various fields where solid-liquid or solid-solid separation is required, thanks to its ability to effectively separate materials of different densities, particle sizes and shapes. It has unique advantages in gravity separation of fine-grained materials.

Particle size analysis in warehouses (such as sand, ore, soil)

Standard sieving test

Powder classification

Quality control and experimental research

The Tap Sieve Shaker is a commonly used particle size analysis device in laboratories. Its primary purpose is to accurately sieve and analyze various powders and granular materials.

Precise Particle Size Analysis: Using a series of standard sieves with varying apertures, the Tap Sieve Shaker can separate material samples into distinct particle size ranges. This helps determine the sample's particle size distribution and provides reliable data for evaluating material properties.

Material Separation and Classification: This device can quickly and efficiently separate mixed materials into individual components of varying particle sizes, which is crucial for applications requiring material classification.

Simulated Manual Sieving: The Tap Sieve Shaker's unique combination of up-and-down tapping and flat vibration simulates the motion of manual sieving. It effectively removes particles clogged in the sieve apertures, ensuring a thorough sieving process and consistent results.

Quality Control and Research: The Tap Sieve Shaker plays a key role in any process requiring precise control of material particle size. It can be used for product quality inspection or as a testing tool to determine material properties during new material development. In summary, the Tap Sieve Shaker's primary purpose is to provide a standardized testing method for materials requiring accurate and repeatable screening results. Its core value lies in providing reliable particle size data to serve quality control and research and development.

The price of a Tap Sieve Shaker varies significantly, influenced by a variety of factors. The price of the device primarily depends on model specifications, manufacturing materials, market supply and demand, and customization requirements. These factors collectively determine the market price of different sieve shakers, leading to significant cost differences between small-scale laboratory equipment and large-scale industrial equipment.

The price of the tap sieve shaker varies greatly due to factors such as model, specification, material, manufacturer and market supply and demand.

Model and specification: The price of shakers of different sizes, processing capacity and bed structure varies greatly. For example, the price of a small shaker for laboratory use and a large shaker for industrial use varies greatly.

Material: The quality and cost of the materials used to manufacture the shaker (such as bed material, frame material, etc.) will affect the price.

Market supply and demand: The market supply and demand relationship will also affect the price of the shaker.

Customization requirements: If you have special customization requirements, such as special bed design or material, the price will increase accordingly.

The Tap Sieve Shaker is a commonly used particle size analysis device in laboratories, primarily used for precise screening and particle size analysis of various powders and granular materials. Its core function is to simulate the tapping action of manual sieving, effectively dispersing materials and removing particles clogged in the sieve apertures, thereby ensuring accurate and consistent screening results.

Research and Quality Control: In industries such as chemicals, food, and building materials, the Tap Sieve Shaker is a key device for product quality control and new material development. It helps researchers and quality control personnel determine the particle size distribution of materials, which is crucial for evaluating product performance, stability, and production process reliability.

Soil and Geological Analysis: In geology and civil engineering, the Tap Sieve Shaker is commonly used to analyze particle size distribution in samples such as soil and rock fragments. Sieving can reveal soil composition, providing essential data for projects such as foundation design and roadbed filling. Abrasives and Powder Metallurgy: In the abrasives and powder metallurgy industries, the Tap Sieve Shaker is used to measure the particle size of products such as metal powders and ceramic powders. Precise particle size control is critical for ensuring product hardness, density, and sintering properties.

Food Processing: In the food industry, it is used to sieve flour, starch, spices, grains, and other products to ensure that the product particle size meets standards, which affects the product's taste, solubility, and processing performance.

Test Analysis Sieve is a sieve for separating mixtures. It mainly makes the mixture of particles of different...

Sieve Analysis Test is mainly used for grading the particle size composition of various powder materials,...

Soil Test Sieve can be used for soil grading, screening, analysis, testing, filtering various soils, widely used...

Standard Sieves standard sieve is a tool for particle size classification and particle size detection of material...

What is 4.75mm soil sieve ? The 4.75mm soil sieve is primarily used for particle grading analysis of bulk materials such as soil, sand, gravel, and aggregate. The core component of ...

What is 2mm soil sieve? A 2mm soil sieve is a fundamental and crucial tool. Its primarily used for pre-processing and sorting soil samples, separating coarse particles (larger than ...

Size sieve for soil mainly refers to the sieve frame diameter (commonly used 200mm, 300mm, etc.) and the sieve hole size (ranging from 0.075mm to 60mm). The sieve frame diameter is ...

Soil sieve prices range from $3 to $500. A soil sieve is a tool used to separate materials such as soil, sand, and compost by particle size. It is used in a variety of applications,...

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap