Tuesday January-20 2026 16:29:34

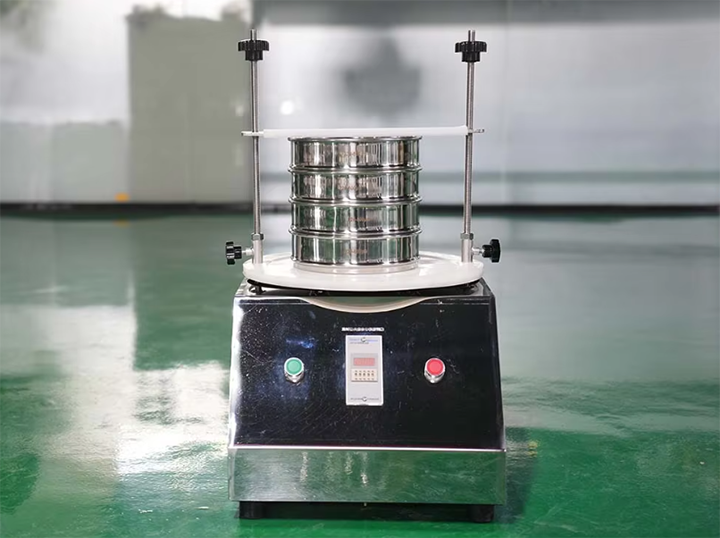

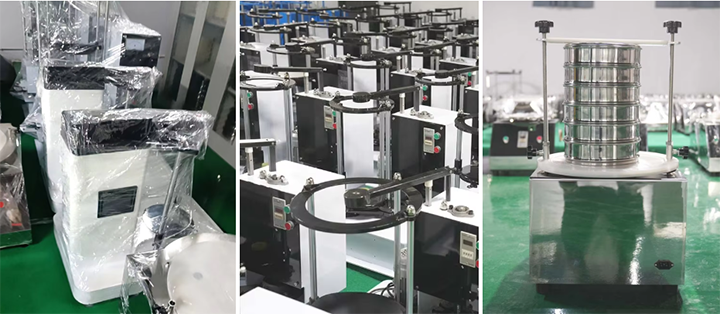

When testing samples, sample test sieve machine is typically used to sieve them. Sieving determines whether the sample's particle size, appearance, and other characteristics meet requirements. Different types of sieve machines can be selected depending on the material state of the sample, such as vibrating test sieves, impact sieves, and ultrasonic test sieves. All three types can install 1-8 layers of sieves simultaneously, achieving multi-level grading. They can also install 200mm or 300mm sieves and offer sieves made of different materials such as stainless steel and nylon.

The particle size of the sieves in a sample test sieve machine conforms to national standards, making it suitable for comparative testing or quality determination of samples. Only a small number of samples are needed for testing; if the sample meets requirements, production can proceed; otherwise, losses from mass production can be avoided. The sample test sieve machine offers fast testing speeds, requiring only a few minutes, and can simultaneously install 1-8 sieves with different aperture sizes, resulting in high sieving efficiency. By conducting sample testing with a sieve machine beforehand, it's possible to determine the most suitable sieve type, aperture, vibration mode, and material. This provides data for formal production and reduces trial-and-error costs.

Sample test sieve machines can be selected from vibrating sieve machines, impact sieve machines, and ultrasonic sieve machines. Each of these three types has its own characteristics. Below is an introduction to the three types of sieve machines, along with a comparison table.

Vibrating sieve machines have a relatively gentle sieving force, allowing the sample to pass through the sieve openings through dispersion and gravity. They are suitable for routine particle size analysis and applications requiring non-destructive sieving. They are suitable for sieving dry, free-flowing particles, but not suitable for sieving samples that easily agglomerate, contain water, oil, have high static electricity, or are fibrous.

Impact sieve machines strike the sample with rotation and vertical force. They have a stronger impact force and are suitable for fine particle samples that easily agglomerate, are sticky, and easily clog the sieve. They are less suitable for brittle, fragile samples or samples requiring preservation of their original crystalline form, as this may cause secondary breakage of the particles.

Ultrasonic test sieve machines, equipped with an ultrasonic system, offer high sieving frequency and relatively low amplitude. This allows them to sieve extremely fine, highly electrostatic, easily agglomerated, sticky, and low-density micro-powder samples. It also reduces sieve clogging during the sieving process.

| Comparison Dimension | Vibrating Test Sieve Shaker | Tap Test Sieve Shaker | Ultrasonic Test Sieve Shaker |

| Working Principle | Motor generates three-dimensional vibration to make samples jump and stratify on the sieve mesh | Mechanical tapping + vertical vibration, simulates manual sieving | Superimposes high-frequency ultrasonic waves on vibration to prevent sample agglomeration |

| Main Movement Mode | horizontal + vertical + tilt | Vertical vibration + periodic tapping | Vibration + high-frequency ultrasonic micro-vibration |

| Applicable Sample Type | General powder, granules, sand | Coarse particles, irregular particles, heavier materials | Ultra-fine powder, lightweight powder, easily agglomerated samples |

| Typical Particle Size Range | 20 μm ~ 125 mm | 50 μm ~ 125 mm | 5 μm ~ 300 μm |

| Adaptability to Agglomerated Samples | General | Poor | Excellent |

| Sieving Efficiency | High | Medium | Very High |

| Sieving Precision | High | Medium | Highest |

| Mesh Blocking Tendency | Medium | High | Extremely Low |

| Damage to Sieve Mesh | Small | Large | Small |

| Noise Level | Medium | High | Medium |

| Single Test Time | 1-10 minutes | 5-15 minutes | 1-5 minutes |

| Common Application Fields | Building materials, chemical industry, food, pharmaceuticals | Coal, metallurgy, grains, soil analysis | Pharmaceuticals, metal powder, battery materials, 3D printing powder |

| Equipment Cost | Medium | Low | High |

| Maintenance Complexity | Low | Medium | High |

The price of a sample test sieve machine depends on factors such as the size and material of the sieve frame, the machine's functions, and the number of sieves. For a vibrating test sieve machine with 5-8 sieve layers and digital timing and speed control, the price is typically between $900 and $1800. For a tapping vibrating sieve machine with basic tapping and rotation functions and mechanical timing or simple digital control, the price is around $800 to $1500. For an ultrasonic test sieve machine with a vibrating sieve main unit, an ultrasonic generator, and 1-2 sieves, the price is typically around $1800 to $3200.

| Sample Name | Common Sieve Mesh (Mesh) | Corresponding Particle Size Range (approx. μm / mm) | Description |

| Soil | 10, 20, 40, 60, 100, 200 | 2.0 mm ~ 75 μm | Commonly used in geotechnical, agricultural, and environmental testing |

| Construction Sand | 4, 8, 16, 30, 50, 100 | 4.75 mm ~ 150 μm | Used for gradation and content analysis |

| Coarse Aggregate | 4, 8, 16, 20, 40 | 4.75 mm ~ 0.45 mm | Often used with vibratory sieve shakers |

| Cement | 80, 100, 200, 325 | 180 μm ~ 45 μm | 325 mesh is commonly used for fineness testing |

| Iron Powder | 60, 100, 200, 300 | 250 μm ~ 48 μm | Powder metallurgy, magnetic materials |

| Flour | 80, 100, 120, 150 | 180 μm ~ 100 μm | Commonly used in the food industry |

| Quartz Powder | 100, 200, 325 | 150 μm ~ 45 μm | Electronics, chemical industry, glass manufacturing |

| Ore Sand | 20, 40, 60, 100, 200 | 850 μm ~ 75 μm | Mineral processing and analysis |

| Fertilizer Granules | 6, 8, 10, 20 | 3.35 mm ~ 0.85 mm | Particle size uniformity testing |

| Pharmaceutical Powder | 80, 100, 200, 325 | 180 μm ~ 45 μm | Complies with pharmacopoeia requirements |

A cement plant needed to test mineral powder samples to observe whether the particle size distribution met production standards. A Sample Test Sieve Machine was used, equipped with 200-mesh, 150-mesh, and 100-mesh sieves. First, the sieve machine was placed on a level surface. Then, the sieve layers were assembled from bottom to top according to mesh size. A 50g sample of mineral powder was placed in the top sieve. The vibration frequency was adjusted to 1200 times/minute, and the sieving time to 10 minutes, then the equipment was started. After sieving, the mass of residual mineral powder sample in each layer was weighed. Calculations showed that the proportion of material passing through the 200-mesh sieve was 92%, which meets the industry standard of ≥90%, thus the batch of mineral powder was deemed qualified.

The sample test sieve machine provides a method for determining particle size and quality for different samples, such as powders and granules. This allows companies to avoid the risk of quality defects caused by mass production by testing samples in advance. If you are having trouble choosing between the three types of sieves – vibrating sieve, tapping sieve, and ultrasonic sieve – as well as the type and material of the sieve mesh, you can contact DaHan Machinery online to find the right sieve for your sample testing.

vibrate test sieve for bulk material

vibrate test sieve for bulk material is a device used for screening or particle size analysis of granular, powdery, and other bulk materials...

test sieve for particle analysis material

test sieve for particle analysis material can be used for sieving and particle size analysis of granular materials such as mung beans, soil, and sand...

material separation test sieve

material separation test sieve separates materials such as powders, granules, and sand through sieving, thereby determining the particle size distribution or removing impurities...

test sieve for powder and material

test sieve for powder and material is used to perform particle size distribution analysis, grading...

Jan 20, 2026

When testing samples, a sample test sieve machine is usually used to sieve the samples. By sieving, i...

Jan 14, 2026

test sieve for particle analysis material

test sieve for particle analysis material can be used for sieving and particle size analysis of granu...

Jan 06, 2026

vibrate test sieve for bulk material

vibrate test sieve for bulk material is a device used for screening or particle size analysis of bulk...

Dec 30, 2025

automatic vibrating test sieve with sample

automatic vibrating test sieve with sample uses a motor to drive the sieve to vibrate, so that the sa...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap