Tuesday December-16 2025 17:56:15

test sieve for powder and material is used to perform particle size distribution analysis, grading, or impurity inspection of powdered materials according to sieving requirements. Its design, manufacture, and use comply with international standards such as ISO 3310-1 and ASTM E11, thus providing accurate and repeatable sieving results.

Test sieves for powder and material are available in different diameters, including 200mm, 300mm, and 450mm, sieving powders and other materials with particle sizes ranging from 125mm to 20μm. The sieve can be equipped with 1-12 layers of sieve frames. The commonly used 125mm sieve frame material is 304 or 316 stainless steel; for some special powder materials, brass, nickel-plated steel, or nylon are also used.

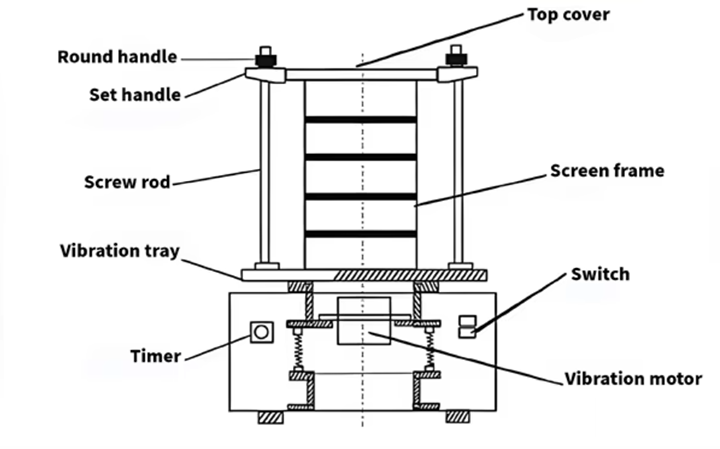

The test sieve for powder and material includes components such as sieve frames, sieve mesh, and support structure. Half-height or full-height sieve frames can be selected to accommodate different sample volumes. The sieve is precision-woven from stainless steel wire; for extremely fine powders, electroformed microporous sieves are also used. The supporting structure ensures the sieve does not deform during vibration or shaking. The test sieve separates powder components of different particle sizes by vibrating or shaking the powder material through the sieve openings.

Sieving removes larger or agglomerated materials from powders, resulting in a uniform particle size distribution. This is crucial for powder flowability, compaction, and mixing uniformity. Uniform particle size can improve the chemical reaction rate and heat treatment effect of materials. For example, in metal powder metallurgy or ceramic sintering, uniform particle size contributes to densification and structural homogeneity. For powders that are easily hygroscopic or oxidized, sieving also prevents agglomeration and clumping, maintaining the powder's processability and stability. Standardized testing procedures ensure repeatable and comparable data, providing objective evidence for powder material quality control and formulation optimization.

Based on the sieve material, aperture shape, and application method, test sieves for powder and material can be divided into several types, suitable for different types of powder materials.

Metal wire mesh sieves are usually woven from stainless steel or brass wire. They have uniform apertures and are wear- and corrosion-resistant, suitable for dry powder materials such as chemical powders, ceramic powders, or metal powders.

Perforated plate sieves are made by punching holes in a metal plate. The holes are mostly round, and the structure is robust and durable, suitable for high-hardness powder materials such as ore powders and abrasive powders.

Nylon or polyester sieves are suitable for wet screening or handling easily corroded chemical powders. They are lightweight and rust-resistant. During wet screening, the powder material easily passes through the sieve without being damaged by adhesion or corrosion.

According to aperture shape, they can be divided into square-hole sieves and round-hole sieves. Square-hole sieves are suitable for analyzing the uniformity of powder materials, ensuring accurate measurement of particle size distribution; round-hole sieves are suitable for powder materials with good flowability, such as food powders or pharmaceutical powders.

According to application method, they can be divided into vibrating sieves and hand-cranked sieves. Vibrating sieves rapidly sieve large quantities of powder using mechanical vibration, suitable for large batches of samples in industrial or laboratory settings. Hand-cranked sieves are suitable for fine analysis of small quantities of laboratory samples, offering simple operation and controllable sieving time and intensity.

When operating a test sieve for powder and material, the appropriate sieve and material should be selected based on the powder's particle size distribution, flowability, and adhesiveness. Powders prone to agglomeration should be pre-treated to break up the particles and prevent clogging. Light powders should be processed in a sealed sieve box to reduce dust and material loss. For sticky powders, the vibration frequency can be appropriately reduced to prevent material adhesion to the sieve surface. Before starting the equipment, the powder should be evenly spread on the top sieve, ensuring the feed rate does not exceed 1/3 of the effective sieve area to avoid accumulation affecting sieving accuracy. During sieving, set a reasonable time according to the powder characteristics; fine powders can have a longer sieving time. After completion, promptly clean the sieve of any residual powder and regularly check the sieve aperture accuracy to ensure accurate and reliable test data.

The price of a test sieve for powder and material depends on factors such as material, mesh size, and diameter. For a standard 200mm diameter sieve, the price typically ranges from $40 to $180. Common mesh sizes from 100 to 325 mesh are less expensive, while extremely fine or coarse sieves are more expensive due to complex manufacturing processes. A laboratory vibrating sieve system with a diameter of 200-300mm, supporting 1-8 layers of sieving, costs between $130 and $800 per unit. The price of sieves made with special materials is typically 20%-50% higher than those made with 304 stainless steel.

Test sieves for powder and material are used for particle size analysis, uniformity testing, and quality control of powders. Screening machines can classify the particle size of plastic powder, pigment powder, catalyst powder, etc.; they are used for particle distribution detection of traditional Chinese medicine powder, tablet powder, or chemical powder; they can screen flour, milk powder, seasoning powder, etc., removing lumps or foreign matter to ensure product taste; and they are used for particle size analysis of cement, ceramic powder, or metal powder to optimize processing technology and material properties.

Through the test sieve for powder and material, high-precision and repeatable powder particle size measurement can be achieved, making it an indispensable tool in powder research and development, production, and quality control. Furthermore, its rigorous operating procedures are a crucial link in ensuring reliable data, optimizing processes, and controlling product quality in fields ranging from food quality to new material performance.

vibration screening test sieve

vibration screening test sieve is a sieving device used to determine the particle size of dry, wet, or free-flowing materials....

vibration sieve for material testing

vibration sieve for material testing determine particle size distribution to assess material homogeneity and quality stability...

Sieve Mesh is a precision tool made of metal, nylon, or other synthetic materials, with a uniform pore size...

For Laboratory Sieves Price from $200 to $60 USD, depending on the sieve diameter, mesh range, material, and quantity...

Dec 16, 2025

test sieve for powder and material

Test sieve for powder and material is used to perform particle size distribution analysis, grading, o...

Dec 09, 2025

Electric sieve shakers price from $200.00 to $680.00, depending on factors such as the material, mode...

Dec 04, 2025

Chemical Material Standard Laboratory Vibrating Sifter

Chemical Material Standard Laboratory Vibrating Sifter is a device used to determine the particle siz...

Dec 02, 2025

vibration screening test sieve

Vibration screening test sieve separates materials through vibration, thereby determining the particl...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap