Tuesday December-02 2025 17:31:21

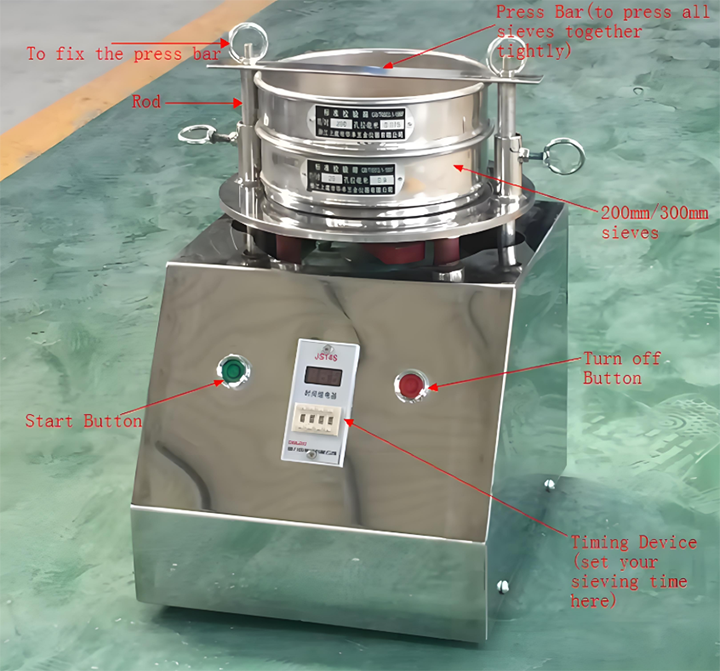

vibration screening test sieve is a sieving device used to determine the particle size of dry, wet, or free-flowing materials. It achieves separation based on particle size through vibration and is used for batch processing or continuous sieving.

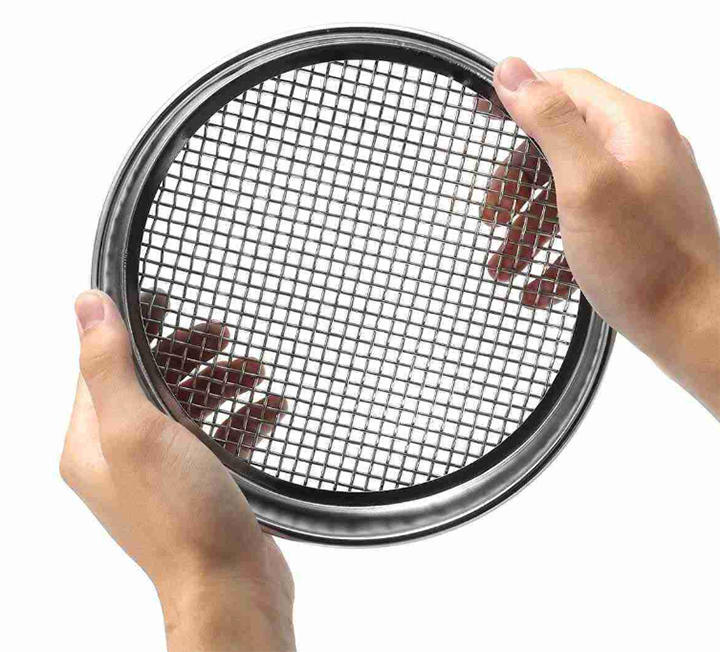

The basic structure of a vibration screening test sieve consists of two parts: a sieve frame and a sieve mesh. The sieve frame is usually circular, with common diameters of 200mm or 300mm, and a height generally between 50mm and 100mm. The sieve frame is mostly made of stainless steel or aluminum alloy; stainless steel is corrosion-resistant and durable, while aluminum alloy is lightweight and easy to move and stack. The sieve mesh is the core component of the test sieve, with a wide range of apertures, from a few micrometers to several millimeters. It typically uses standardized specifications, such as ASTM, ISO, or GB standards, to ensure the comparability and accuracy of the sieving results. The edges of the sieve mesh are fixed to the sieve frame using clamping or welding to prevent loosening or detachment.

A vibration screening test sieve allows particulate material to pass through a sieve opening, either manually or mechanically. Smaller particles fall to the lower layer, while larger particles are retained at the top.

Compared to manual sieving, vibrating sieving provides stable and controllable vibration, making the sieving process faster. Manual sieving is easily affected by operator experience and force, resulting in poor repeatability. Vibrating sieving, through mechanical control, ensures consistent results. For small particles and high-density materials, vibrating sieving significantly improves sieving accuracy, reduces human error, and increases experimental and production efficiency.

Vibration screening test sieves can be classified according to their vibration method into electromagnetic vibrating sieves, mechanical vibrating sieves, and manual vibrating sieves. Electromagnetic and mechanical sieves can be equipped with 1-8 layers of screens for multi-level grading of materials. Manual sieves only require mastering the sieving technique.

Electromagnetic Vibrating Screen: Driven directly by an electromagnetic vibrator, the screen body undergoes linear, high-frequency, micro-vibration. The vibration frequency is typically 1200–3000 times/minute, with an adjustable amplitude of 1–3 mm. It can handle particles and powders with a diameter of 0.02–5 mm. The vibration force and intensity can be easily adjusted by changing the current or frequency. It is suitable for fine sieving and filtration of light, fine, sticky, and micro-powder materials, and operates with low noise during the sieving process.

Mechanical Vibrating Screen: Driven by a motor, an eccentric wheel or spring generates vibration. Common amplitudes are 3–6 mm, and frequencies are approximately 800–1500 times/minute. It is suitable for sieving particles or coarse powders with a diameter of 0.5–20 mm. Materials are thrown and fall on the screen surface, providing strong conveying and dispersing capabilities. It is suitable for medium-scale experimental or industrial sample pretreatment.

Manual Vibrating Screen: Vibrated by hand-cranking or gently tapping the screen frame; no power supply is required. Suitable for small sample volumes or rapid preliminary screening, often used in teaching or sample preparation stages. The sieve frame diameter is commonly 100–200 mm, and the sieve aperture ranges from 0.05–5 mm. Operation is simple but inefficient and has poor repeatability.

A vibration screening test sieve causes the material to diffuse in a spiral motion across the sieve surface, ensuring uniform sample distribution across the entire sieve surface. This increases the chance of particles passing through the sieve apertures and avoids incomplete screening caused by localized accumulation. The vibration frequency and amplitude can usually be adjusted according to sample characteristics such as density and viscosity, resulting in good repeatability and comparability of screening results. The matching sieve frame and sieve mesh strictly adhere to international or national standards, and the sieve mesh aperture, wire diameter, and weaving process are also legally regulated, ensuring rigorous and referable screening results.

The vibration screening test sieve is used for screening dry, wet, and corrosive materials, such as quartz sand, abrasives, metallurgical powders, flour, salt, sugar, tea, coal powder, soil samples, sludge, and solid waste. It screens powders and granules to determine particle size distribution; detects foreign objects or oversized particles to ensure product purity; and simultaneously separates materials into multiple particle size grades for small-batch production or experimental research. It also screens intermediate or finished products to ensure particle size meets process requirements and quality standards.

During use, the vibration screening test sieve can be cleaned periodically using a soft brush, ultrasonic cleaning, or a dedicated screen cleaning device. For sticky materials, a heated screen or an air jet cleaning device can be used. The vibration frequency and amplitude can be calibrated to ensure uniform material distribution and sufficient stratification. Regularly replenish or replace the dedicated lubricating grease and check bearing temperature and seals. Dahan Machinery can provide process optimization solutions and customize equipment for special materials. The equipment conforms to international standards and has a complete quality control system, ensuring long-term stable performance.

Standard Test Method for Particle-Size Analysis of Soils

Standard Test Method for Particle-Size Analysis of Soils (ASTM D422)aims to accurately determine the size distribution of soil particles...

Soil sieve analysis is a soil particle size determination method based on the principle of mechanical separation...

laboratory sieve with material

laboratory sieve with material are the cornerstone tools for particle size analysis...

Laboratory Sieve for Calcining Clay

Laboratory Sieve for Calcining Clay is a precision sieving device used for processing clay and its calcined products...

material particle size test sieve

material particle size test sieve is a tool used to determine the particle size distribution of solid materials...

Dec 02, 2025

vibration screening test sieve

Vibration screening test sieve separates materials through vibration, thereby determining the particl...

Dec 02, 2025

size sieve for soil is made of stainless steel and can sieve out dust and soil. The fine sieve sizes ...

Nov 29, 2025

material particle size test sieve

material particle size test sieve helps generate a reliable material particle size distribution throu...

Nov 27, 2025

Laboratory Sieve for Calcining Clay

Laboratory Sieve for Calcining Clay has a sieve particle size ranging from 63 μm to 250 μm and can ...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap