Tuesday January-27 2026 16:10:19

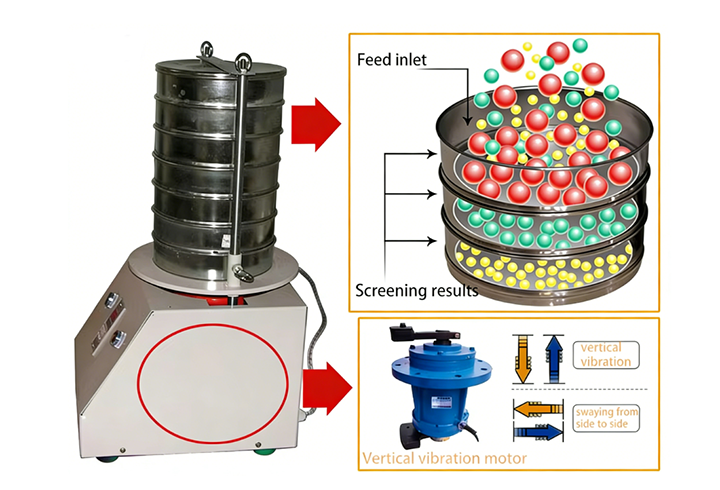

vibratory test sieve with sample loading involves loading the sample to be sieved into a vibrating sieve and then performing a sieving test to determine whether the particle size of the material meets the requirements. The sieving analysis conforms to ASTM standards. The test sieve can measure materials from 0.075mm to 100mm in size; sieves with diameters of 200mm or 300mm can be selected. The sample amount for sieving analysis ranges from 5g to 200g, depending on the sample type and maximum particle size.

Before performing a vibratory test sieve with sample loading, a sieving sample needs to be prepared. A total sample is collected from multiple points in the material pile, conveyor belt, or container using tools such as a sampling shovel or sampler. If the material is wet, it needs to be dried. Then, using a sample divider, the material is evenly divided into two portions, and this process is repeated until the required amount is obtained. The obtained sample is loaded, weighed, and the weight is recorded before proceeding to the next sieving operation.

In the process of vibratory test sieve with sample loading, sieving methods are generally divided into two types based on the application of the material: dry sieving and wet sieving.

Dry sieving requires a test sieve machine to sieve the dried sample. Before sieving, a set of sieves is stacked according to their aperture size. The sample is then loaded onto the top sieve, and sieving is performed for 10-15 minutes. After sieving, the particle size of the sample is measured.

Wet sieving involves loading a wet sample onto a sieve and continuously rinsing it with water. Once the water runs clear, the sample is removed from the sieve and dried. After drying, the sample is weighed, and then the particle size is measured.

| Sample Type | Typical Sample Loading | Common Sieve Sizes |

|---|---|---|

| Sand | 100–500 g | 4.75 mm, 2.36 mm, 1.18 mm, 600 μm, 300 μm, 150 μm |

| Cement | 50–100 g | 90 μm, 75 μm, 45 μm |

| Flour | 50–100 g | 250 μm, 180 μm, 150 μm, 125 μm |

| Soil | 200–500 g | 2 mm, 1 mm, 500 μm, 250 μm, 75 μm |

| Metal Powder | 50–200 g | 150 μm, 106 μm, 75 μm, 45 μm |

| Plastic Pellets | 100–300 g | 4 mm, 2 mm, 1 mm |

| Coal Powder | 50–200 g | 500 μm, 250 μm, 125 μm, 75 μm |

| Pharmaceutical Powder | 20–50 g | 250 μm, 180 μm, 125 μm, 75 μm |

| Fertilizer Granules | 200–500 g | 4 mm, 2 mm, 1 mm |

Vibratory test sieve with sample loading, through quantitative, uniform, and scattered feeding, allows the sample to be evenly spread across the entire effective sieving area of the top sieve. This ensures that the particles are subjected to consistent vibration, resulting in more thorough sieving and more accurate particle size classification. Vibratory sieve testing allows for higher consistency in results from multiple tests conducted under the same parameters, which is beneficial for sample quality control and data comparison. Vibratory sieves can be timed to automatically load samples for sieving, resulting in faster sample separation. During testing, operators only need to set parameters and load samples, avoiding close contact with the vibratory sieve and flying powder, thus preventing mechanical injury and dust inhalation risks. This makes it suitable for testing toxic, harmful, and irritating samples.

Vibratory test sieves with sample loading can be used in laboratory scenarios such as precise particle size detection, raw material incoming quality screening, finished product outgoing verification, production process optimization support, and sample grading.

It can be used for quantitative particle size distribution analysis of powder and granular samples, obtaining particle size data to meet the data analysis needs of experimental research and development and quality testing. In industries such as chemical, food, and pharmaceutical, sieving can be used to remove unqualified impurities from incoming raw materials, verify particle size compliance of finished products, and optimize process parameters by testing intermediate products. It can also utilize sieves of different mesh sizes to separate and collect samples across multiple particle size ranges, meeting subsequent processing needs.

Vibratory test sieves with sample loading improve testing efficiency, saving time compared to manual sieving and providing an advantage for rapid material production. When loading samples, the sample quantity should not be too large to avoid affecting the sieving accuracy of the vibratory sieve test.

When testing samples, sample test sieve machine is typically used to sieve them. Sieving determines whether the sample's particle size...

vibrate test sieve for bulk material

vibrate test sieve for bulk material is a device used for screening or particle size analysis of granular, powdery, and other bulk materials...

test sieve for particle analysis material

test sieve for particle analysis material can be used for sieving and particle size analysis of granular materials such as mung beans, soil, and sand...

material separation test sieve

material separation test sieve separates materials such as powders, granules, and sand through sieving, thereby determining the particle size distribution or removing impurities...

Jan 27, 2026

vibratory test sieve with sample loading

vibratory test sieve with sample loading involves loading the sample to be sieved into a vibrating si...

Jan 20, 2026

When testing samples, a sample test sieve machine is usually used to sieve the samples. By sieving, i...

Jan 14, 2026

test sieve for particle analysis material

test sieve for particle analysis material can be used for sieving and particle size analysis of granu...

Jan 06, 2026

vibrate test sieve for bulk material

vibrate test sieve for bulk material is a device used for screening or particle size analysis of bulk...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap