Tuesday December-30 2025 14:44:20

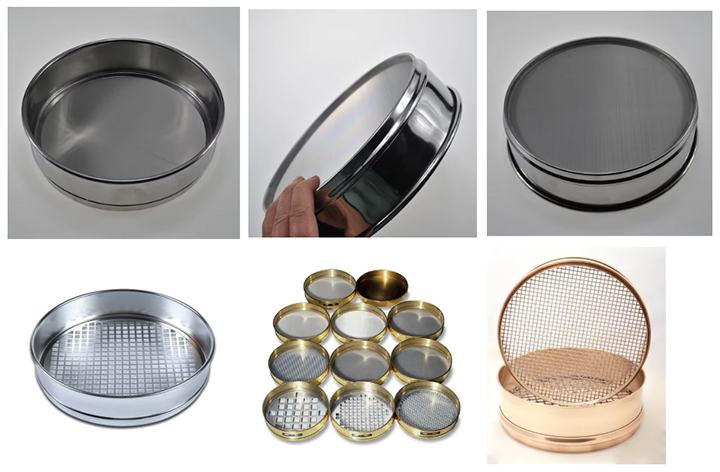

material separation test sieve separates materials such as powders, granules, and sand through sieving, thereby determining the particle size distribution or removing impurities. Test sieves have mesh sizes ranging from 20 μm to 125 mm, meeting the separation needs of materials from ultrafine powders to coarse particles, and are manufactured according to ISO, ASTM, or GB series standards. Test sieves are made of stainless steel, brass, or nylon, and the choice depends on the characteristics of the material.

A material separation test sieve consists of a sieve frame, sieve mesh, and base. The sieve mesh can be made of standard stainless steel wire mesh, wear-resistant steel mesh, brass mesh, or non-metallic mesh such as nylon or polyester used for precision sieving and corrosive materials. Sieve frame diameters are available in 75 mm (3 inches), 100 mm (4 inches), 200 mm (8 inches), and 300 mm (12 inches), with larger diameters allowing for larger sample volumes.

Material separation test sieve methods include dry sieving and wet sieving, depending on the material characteristics. Dry sieving is a commonly used method, suitable for materials with low moisture content, good flowability, and low agglomeration. It is simple to operate and fast. However, for particles smaller than 75μm, materials prone to static electricity, or materials that easily adhere and agglomerate, dry sieving is ineffective, and the screen is easily clogged, leading to distorted results.

Wet sieving uses water or other liquids as a dispersion medium during the separation process. Through the flushing and dispersing action of water flow, it can prevent particle agglomeration, reduce clogging, and wash away fine powder adhering to the particle surface. It can more accurately separate fine materials, providing more reliable results, and is suitable for sludge, clay, slurry, or materials that are not sensitive to moisture. However, the wet sieving process is more complex, requiring a drying step, and the overall time consumption is longer than dry sieving.

Material separation test sieve sieving tests should be performed according to certain standards to ensure the results are reliable. First, the sample is thoroughly mixed and pretreated as necessary, such as drying and impurity removal, to ensure representativeness. Select appropriate sieve apertures according to the testing standards and stack them in descending order of aperture. Pour the sample evenly into the top sieve and sieve manually or mechanically. During sieving, control the time, vibration frequency, and amplitude to ensure complete material separation. Weigh and record the residual material on each sieve layer, and calculate the particle size distribution to provide data support for material performance evaluation.

The price of a material separation test sieve depends on its precision level, material, size, brand, etc. A single stainless steel test sieve costs between $7 and $80, while a single laboratory-grade precision test sieve costs between $50 and $150. A standard 200mm diameter stainless steel sieve set, with 5-8 sieves and a bottom cover, costs approximately between $150 and $400.

On construction sites, material separation test sieves are used to screen gravel and sand, analyzing the ratio of coarse to fine aggregates to ensure concrete strength and workability meet mix design requirements. Cement plants use 0.075mm or 0.045mm square-hole sieves to determine powder fineness, monitor grinding processes, and ensure product setting time and early strength. Geological laboratories use standard sieves to determine soil particle size distribution, providing engineering parameters for roadbed filling or slope design. Flour and milk powder processing companies use food-grade stainless steel sieves to control product fineness, prevent clumping, and ensure good taste and solubility. Pharmaceutical factories use vibrating sieves to separate powdered or granular raw materials, removing impurities and ensuring uniformity of drug composition and accurate dosage. Beyond these applications, material separation tests are also widely used in the food, chemical, and construction industries.

Material separation test sieves transform complex particle groups into precise particle size distribution data. From core sieve aperture and material selection to dry or wet sieving methods, and diverse types, they meet the material separation needs of different industries. In practical applications, whether it's separating materials from impurities or determining the particle size distribution of materials, the material separation test sieve can meet the requirements.

test sieve for powder and material

test sieve for powder and material is used to perform particle size distribution analysis, grading...

vibration screening test sieve

vibration screening test sieve is a sieving device used to determine the particle size of dry, wet, or free-flowing materials....

vibration sieve for material testing

vibration sieve for material testing determine particle size distribution to assess material homogeneity and quality stability...

automatic vibrating test sieve with sample

The Automatic Vibrating Test Siev with Sample uses a motor to vibrate the sieve, ensuring the sample is evenly distributed within the sieve and sieving according to particle size...

Dec 30, 2025

material separation test sieve

Material separation test sieve separates materials such as powder, granules, and sand by screening, t...

Dec 24, 2025

automatic vibrating test sieve with sample

automatic vibrating test sieve with sample uses a motor to drive the sieve to vibrate, so that the sa...

Dec 16, 2025

test sieve for powder and material

Test sieve for powder and material is used to perform particle size distribution analysis, grading, o...

Dec 09, 2025

Electric sieve shakers price from $200.00 to $680.00, depending on factors such as the material, mode...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap