Wednesday January-14 2026 08:31:22

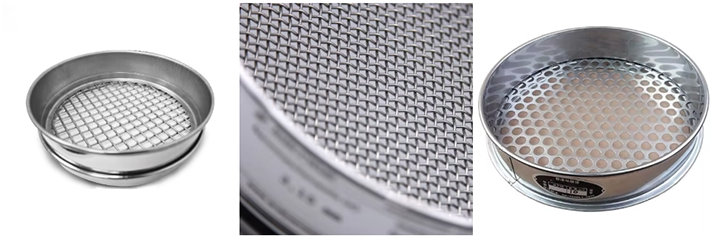

test sieve for particle analysis material can be used for sieving and particle size analysis of granular materials such as mung beans, soil, and sand. Its sieve aperture ranges from 20 micrometers to 125 millimeters. Common sieve frame diameters include 200 millimeters and 100 millimeters, facilitating compatibility with various equipment. The sieve frame is made of corrosion-resistant stainless steel, featuring a robust structure, long service life, and suitability for frequent reuse and easy cleaning and maintenance. The sieve mesh is typically made of high-precision woven metal wire mesh; for micron-level ultrafine sieving, electroformed microporous sieves can also be used. The product conforms to international standards such as ASTM E11 or ISO 3310-1.

When using test sieve for particle analysis material for sieving, stainless steel or brass sieve frames are selected based on the characteristics of the particles. Then, single or multiple sieves are selected and assembled according to the sieving requirements. When selecting multiple sieves, it is important to place the sieve with the largest aperture at the top and the sieve with the smallest aperture at the bottom, so that particles smaller than the aperture can pass through the sieve while particles larger than the aperture are retained. The particles on each sieve are then weighed to calculate the particle size distribution.

Using test sieve for particle analysis material ensures consistent product quality. Particles that are too large or too small can affect usability; sieving ensures that the particle size is within the required range. Particle size can affect material flowability, bulk density, and reaction rate. Through sieving analysis, engineers can control grinding time, avoiding over-grinding or under-grinding, thus optimizing the production process and efficiency. When quality problems arise in the produced products, test sieves can perform particle size analysis to determine which production equipment is malfunctioning. The sieving results from sieves are accurate and reliable, unaffected by particle shape, color, or optical properties. Furthermore, test sieves worldwide have standardized aperture sizes, facilitating data comparison.

| Sieve size (US Sieve #) | Sieve aperture size (mm) | Sieve aperture size (μm) | Mesh (approximately equivalent) |

| 4 | 4.75 mm | 4750 μm | 4 mesh |

| 8 | 2.36 mm | 2360 μm | 8 mesh |

| 10 | 2.00 mm | 2000 μm | 10 mesh |

| 16 | 1.18 mm | 1180 μm | 16 mesh |

| 20 | 0.850 mm | 850 μm | 20 mesh |

| 30 | 0.600 mm | 600 μm | 30 mesh |

| 40 | 0.425 mm | 425 μm | 40 mesh |

| 50 | 0.300 mm | 300 μm | 50 mesh |

| 60 | 0.250 mm | 250 μm | 60 mesh |

| 70 | 0.212 mm | 212 μm | 70 mesh |

| 100 | 0.150 mm | 150 μm | 100 mesh |

| 140 | 0.106 mm | 106 μm | 140 mesh |

| 200 | 0.075 mm | 75 μm | 200 mesh |

| 230 | 0.063 mm | 63 μm | 230 mesh |

| 325 | 0.045 mm | 45 μm | 325 mesh |

| 400 | 0.038 mm | 38 μm | 400 mesh |

When sieving particulate materials, dry sieving or wet sieving can be chosen depending on the state of the material. Dry sieving is simpler to operate, while wet sieving is more time-consuming. Below are the differences between the two types of test sieves for particle analysis materials.

Dry sieving involves passing dry, free-flowing particulate materials through a series of sieves with different aperture sizes without liquid assistance. It is suitable for dry, non-agglomerated particles that are not prone to static electricity.

Wet sieving involves passing slurry or suspended materials through a sieve with the assistance of water or other liquids. It can be used to remove fine powder or separate different particle size components. It is suitable for moist, easily agglomerated particles, particles with high mud content, particles with a lot of powder, and particles that do not dissolve or chemically react in water.

Below is a comparison table of dry and wet sieving:

| Comparison Item | Dry Sieving | Wet Sieving |

| Use of Liquid | Does not use liquid | Uses water or other liquids |

| Suitable Particles | Dry, non-sticky particles | Sticky, agglomerated or fine powder particles |

| Common Sieve Materials | Stainless steel, brass | Nylon, stainless steel, polyester |

| Minimum Effective Particle Size | Generally ≥ 75 μm | Can be < 75 μm |

| Analysis Accuracy | Medium | High |

| Prone to Sieve Blockage | Yes (when there is fine powder) | No (rinsed in liquid) |

| Operation Complexity | Simple | Relatively complex |

| Equipment Requirements | Sieve shaker or hand sieve | Wet sieving device, water source |

| Sample Pretreatment | Usually dried | Generally no need for complete drying |

The test sieve for particle analysis is suitable for various granular materials of different shapes and properties, including large and small particles, such as dry sand, gravel, grains, plastic granules, certain mineral powders, cement, clay, silt, soil, finely ground minerals, pigments, and slurries.

As a machine for analyzing granular materials, the test sieve for particle analysis can be selected for manual sieving or a test sieve machine. When using a manual sieve, ensure even shaking to prevent material scattering. When using a test sieve machine, set an appropriate time, such as 10-15 minutes, to ensure complete sieving. If you are unsure how to choose, you can contact DaHan Machinery online for recommendations on suitable materials and sieve mesh sizes.

material separation test sieve

material separation test sieve separates materials such as powders, granules, and sand through sieving, thereby determining the particle size distribution or removing impurities...

automatic vibrating test sieve with sample

The Automatic Vibrating Test Siev with Sample uses a motor to vibrate the sieve, ensuring the sample is evenly distributed within the sieve and sieving according to particle size...

test sieve for powder and material

test sieve for powder and material is used to perform particle size distribution analysis, grading...

vibration screening test sieve

vibration screening test sieve is a sieving device used to determine the particle size of dry, wet, or free-flowing materials....

Jan 14, 2026

test sieve for particle analysis material

test sieve for particle analysis material can be used for sieving and particle size analysis of granu...

Jan 06, 2026

vibrate test sieve for bulk material

vibrate test sieve for bulk material is a device used for screening or particle size analysis of bulk...

Dec 30, 2025

automatic vibrating test sieve with sample

automatic vibrating test sieve with sample uses a motor to drive the sieve to vibrate, so that the sa...

Dec 30, 2025

material separation test sieve

Material separation test sieve separates materials such as powder, granules, and sand by screening, t...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap